Preparation system for high-performance concrete

A high-performance concrete and preparation system technology, applied in the field of improvement invention, can solve problems such as high cost, low efficiency, unreasonable proportioning, etc., and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

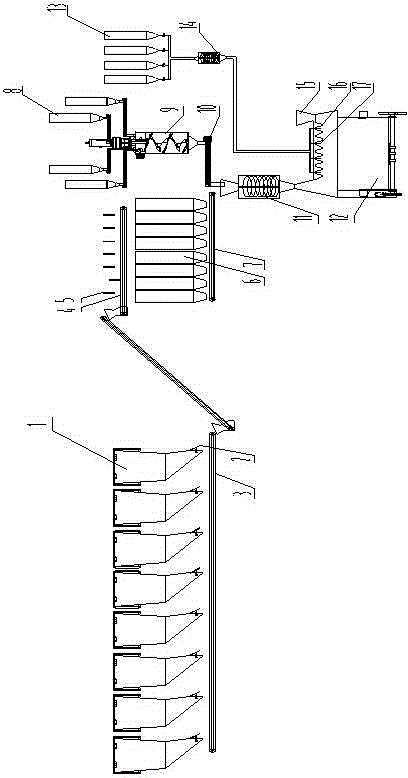

[0014] Accompanying drawing has shown structure of the present invention, further illustrates its relevant details below again in conjunction with accompanying drawing. The high-performance concrete preparation system includes a mixer 12, a conveying device and a power source. The power source is a motor that drives the mixer 12 and the conveying device. The mixer 12 is provided with a water inlet 15. The concrete preparation device also includes a silo 1 , aggregate bin 6, powder bin 8 and liquid tank 13, the first belt conveyor 3 is provided below the bin 1, and the bottom of the bin 1 is provided with a discharge control port 2, preferably a pneumatic bin door; The upper port of the aggregate bin 6 is correspondingly provided with the second belt conveyor 4, and the lower port of the aggregate machine is correspondingly provided with the third belt conveyor 7, that is, the second belt conveyor 4 is provided above the aggregate bin 6, and the third belt conveyor is provided b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com