A thin coal seam quick change dump trailer

A technology for unloading trailers and thin coal seams, which is applied to the arrangement of loading and unloading vehicles, motor vehicles, vehicles with push plates, etc. The effect of widening and reducing the acquisition cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

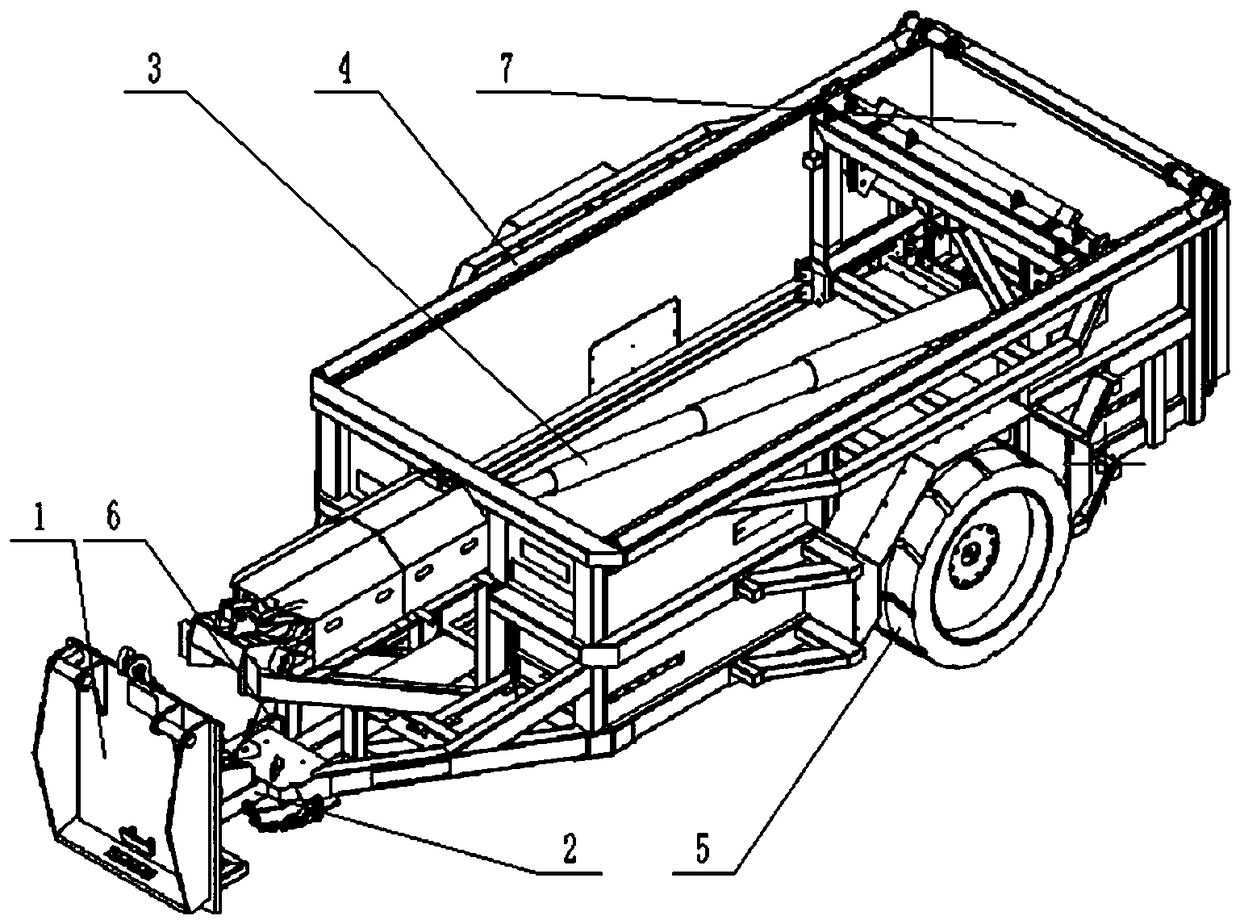

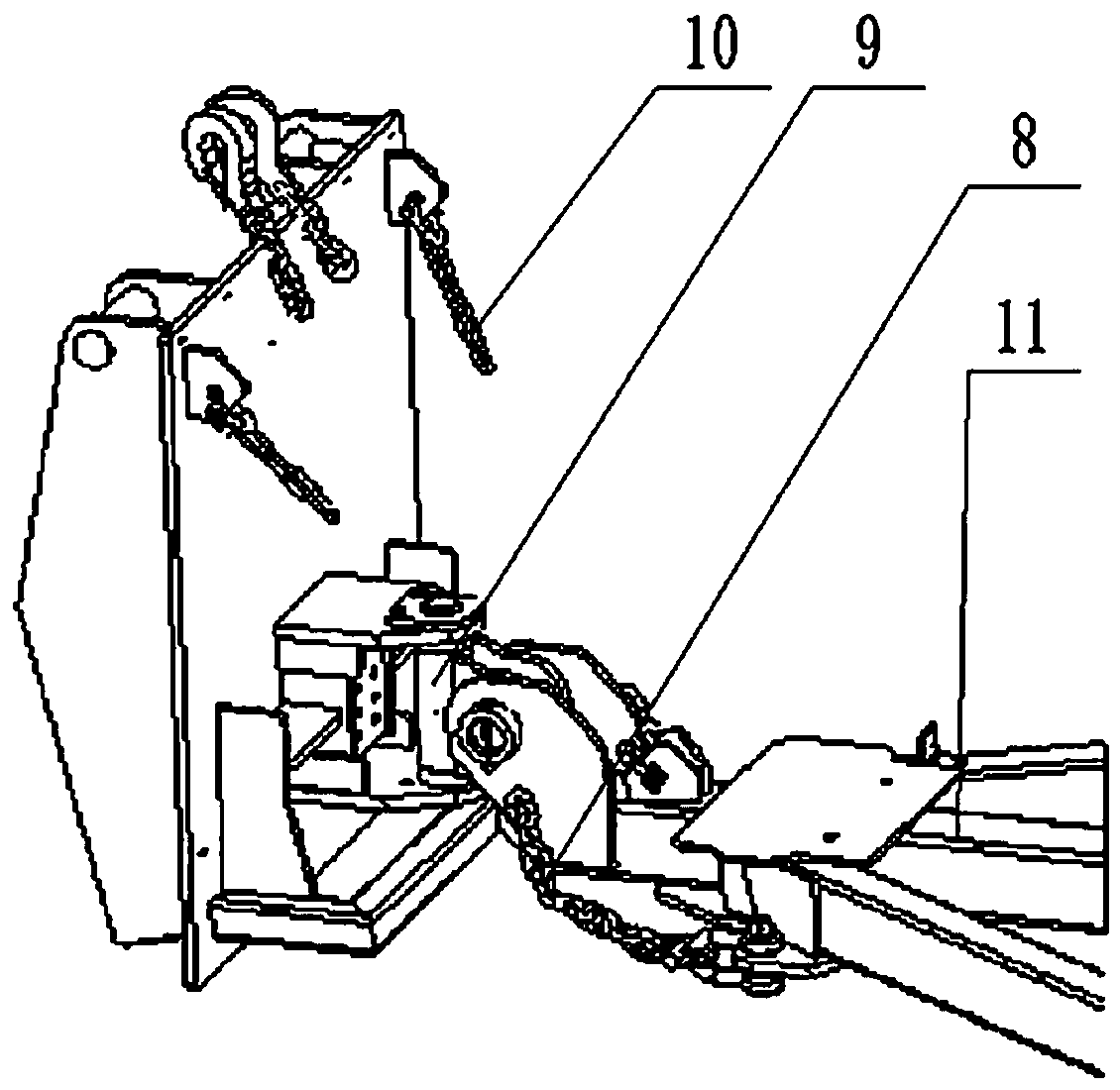

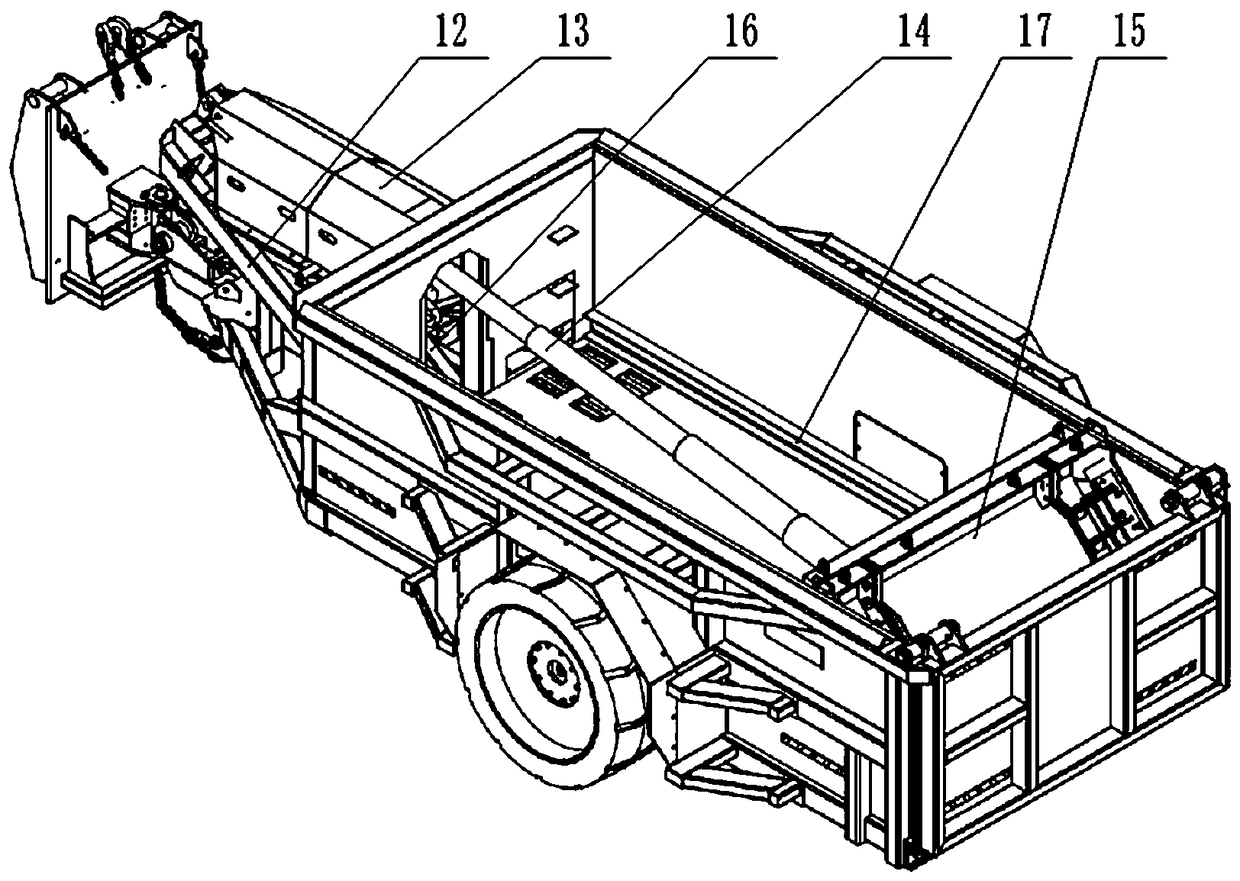

[0024] like figure 1 , 3 The shown thin coal seam quick-change dump trailer includes a car body 4, a traveling device 5 and a hydraulic device 6. The tail of the car body 4 is provided with a bottom-opening unloading door 7, and the triangular support beam 11 at the front end of the car body 4 passes through the connecting device. 2 is connected with a quick-change device 1; the car body 4 is provided with an outward-moving push plate pushing device 3, and the outward-moving push plate pushing device 3 includes a reverse-thrusting three-stage oil cylinder 14 and a push plate 15, and the push plate 15 is horizontally Placed in the vehicle body 4 and connected with the piston rod of the reverse thrust three-stage oil cylinder 14 , the traveling device 5 and the reverse thrust three-stage oil cylinder 14 are both driven by the hydraulic device 6 .

[0025] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com