Train seat table board

A technology of seats and table boards, which is applied in the field of train seat table boards, can solve the problems of poor train maintenance reliability, heavy table board weight, and low production efficiency, and achieve long service life, improved safety, and strong bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

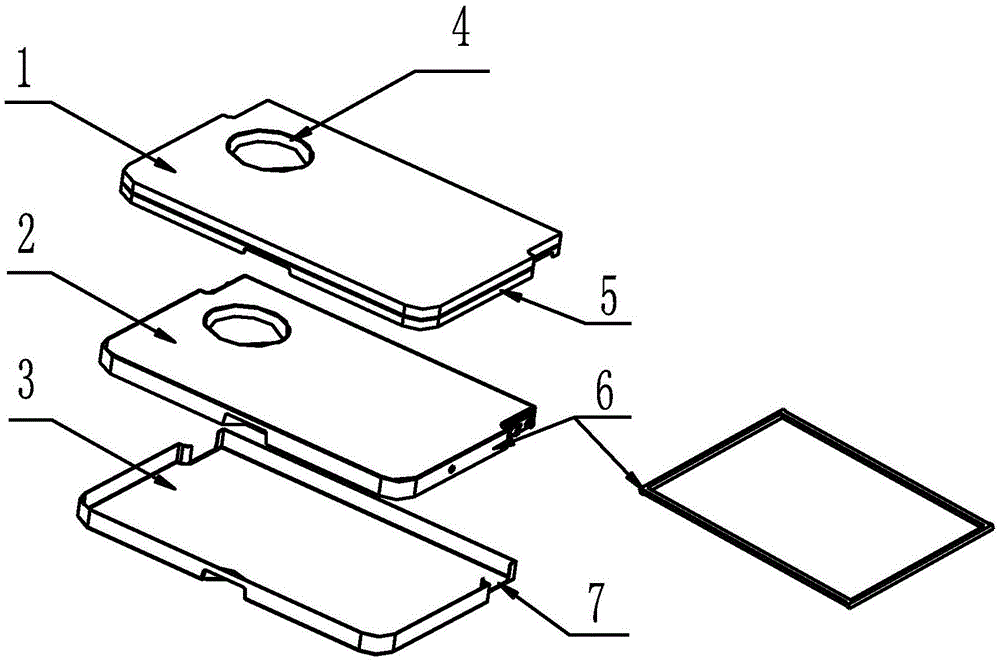

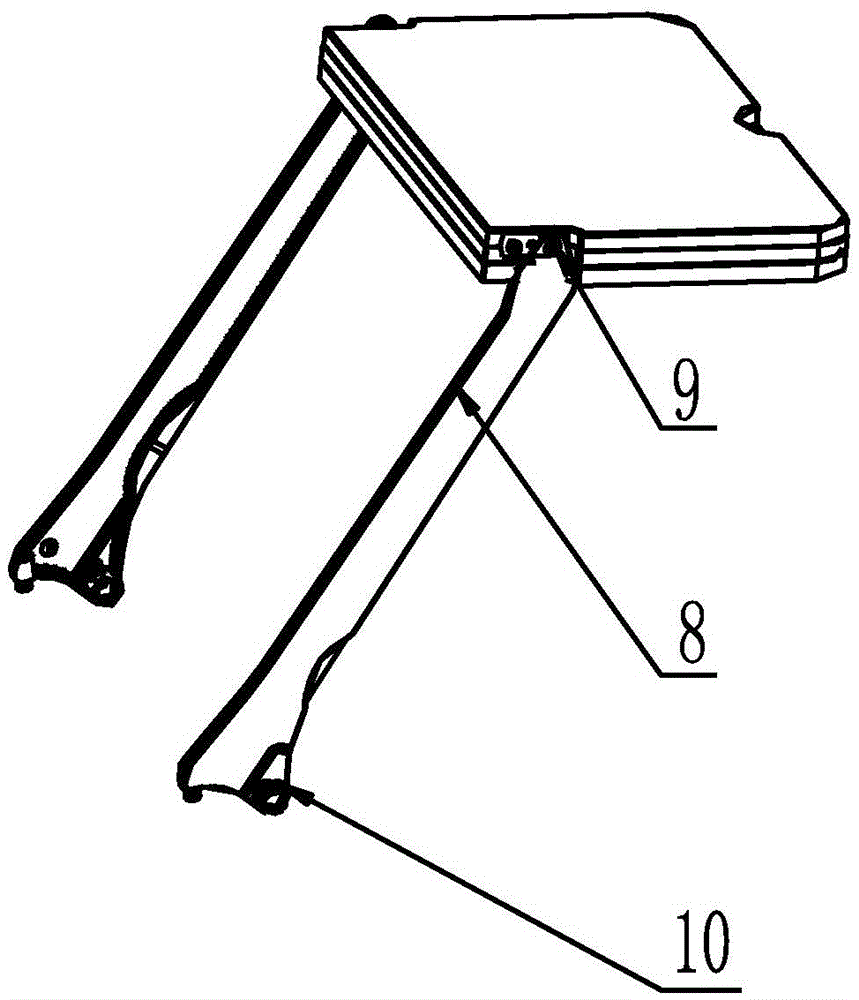

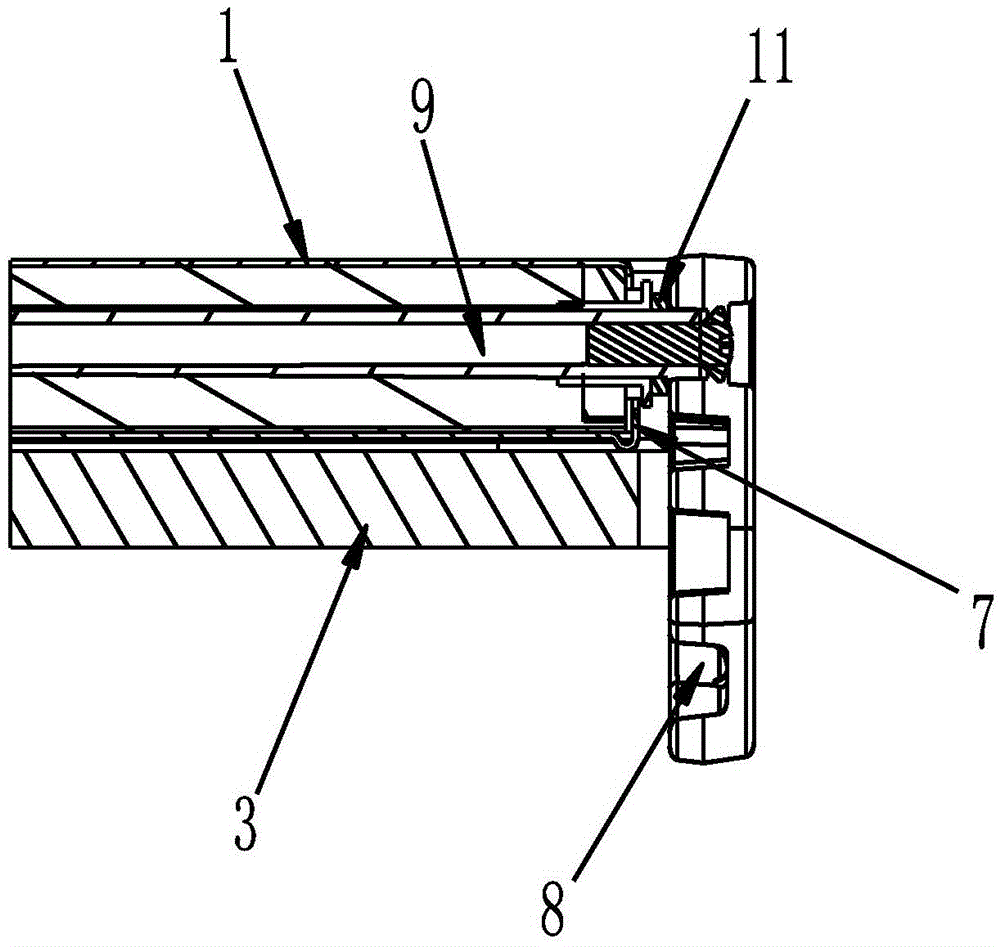

[0017] Such as Figure 1-4 , a train seat table, comprising a dining table, a dining board through shaft 9 and a dining board support arm 8. The dining table board is connected with the dining board support arm 8 by the dining board through shaft 9, and is rotatably connected between the dining table board and the dining board support arm 8.

[0018] The dining table board comprises a panel 1, an inner lining 2, a base plate 3 and an aluminum alloy frame 6.

[0019] The panel 1 and the bottom plate 3 are arranged symmetrically up and down, and correspond to each other. The four sides of the panel 1 protrude downward to form a downward concave cavity, and the four sides of the bottom plate 3 protrude upward to form an upward concave cavity.

[0020] Cup holders 4 are respectively provided on the panel 1 and the inner lining 2 , and overlapping connecting surfaces 5 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com