Pneumatic-electric combined driving flexible biped robot

A biped robot and hybrid drive technology, which is applied in the field of humanoid robots, can solve the problems of poor flexibility and dynamic response characteristics linkage, poor dynamic stability, and low robot walking efficiency, so as to improve terrain adaptability and buffer external impacts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

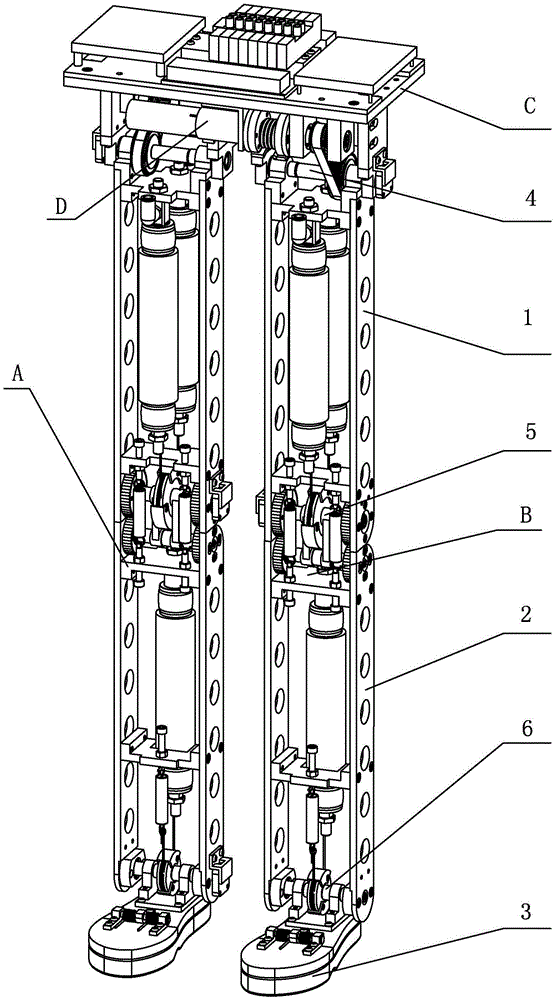

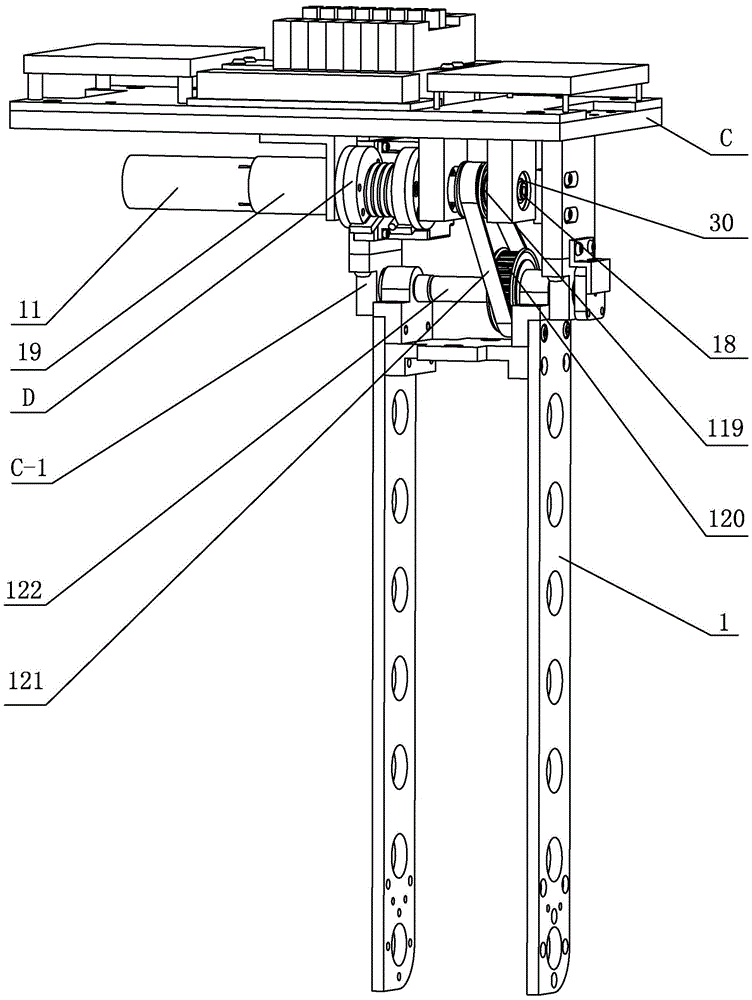

[0016] Specific implementation mode one: combine Figure 1-Figure 8 Explain that a flexible biped robot driven by a gas-electric hybrid in this embodiment includes a left leg A, a right leg B and a pelvis C; the left leg A and the right leg B include a thigh 1, a calf 2, a foot 3, and a hip joint 4. Knee joint 5 and ankle joint 6; left leg A and right leg B are connected through pelvis C, pelvis 3 is rotationally connected with thigh 1 through hip joint 4, thigh 1 is rotationally connected with calf 2 through knee joint 5, and calf 2 is rotationally connected through ankle The joint 6 is rotationally connected with the foot 3;

[0017] The hip joint 4 includes a one-way series elastic driver D and a hip joint transmission mechanism;

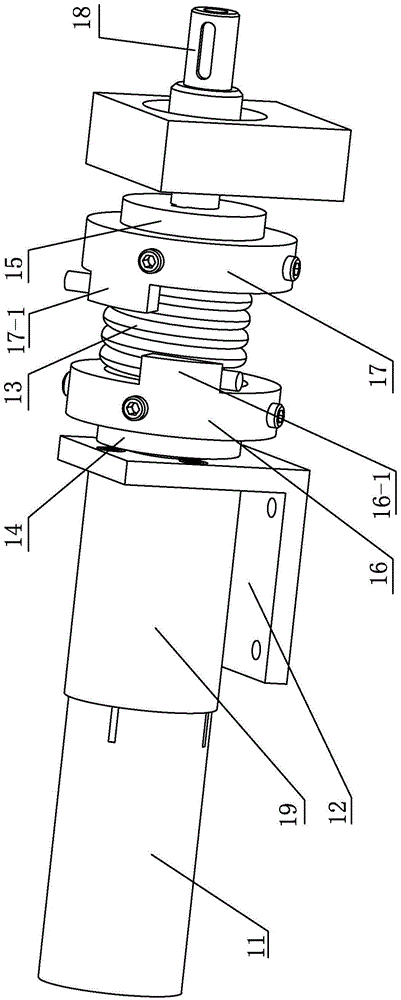

[0018] The one-way series elastic driver D comprises a motor 11, a motor base 12, a torsion spring 13, a first hub 14, a second hub 15, a first snap ring 16, a second snap ring 17 and a hip drive shaft 18;

[0019] The output end of the motor 1...

specific Embodiment approach 2

[0035] Specific implementation mode two: combination Figure 8 To illustrate, the sole 41 of the present embodiment is a thermoplastic polyurethane elastomer rubber airbag. With such a setting, it is easy to obtain light materials and meet the design requirements and actual needs. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Specific implementation mode three: combination Figure 5 and Figure 6 Note that the knee joint 5 in this embodiment also includes another sun gear 25 and another planetary gear 26; the two sun gears 25 are arranged on both sides of the pulley 31, and the other sun gear 25 is fixed on the thigh 1, and the two sun gears 25 are arranged on both sides of the pulley 31. One planetary gear 26 is arranged on both sides of the pulley 31, and the other planetary gear 26 is fixed on the shank 2, and the knee joint drive shaft 23 is installed on the other sun gear 25 through the rotation of the bearing 30, and the knee joint driven shaft 28 is passed through the bearing. 30 is rotatably mounted on another planetary gear 26, and another sun gear 25 meshes with another planetary gear 26. Such setting can reduce the clearance fit between the sun gear and the planetary gear, maintain balance, and ensure the stable and reliable operation of the knee joint. Others are the same as in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com