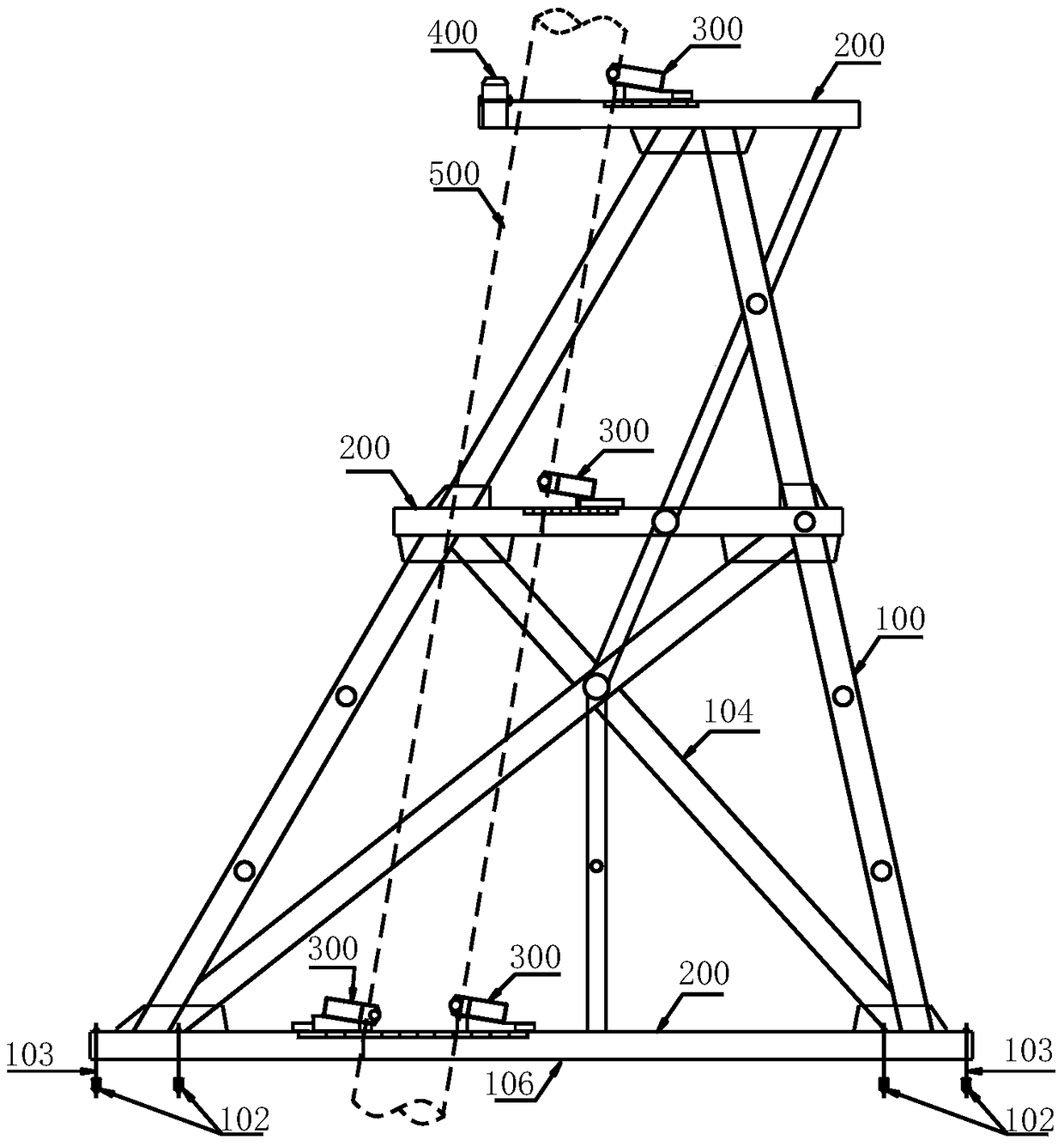

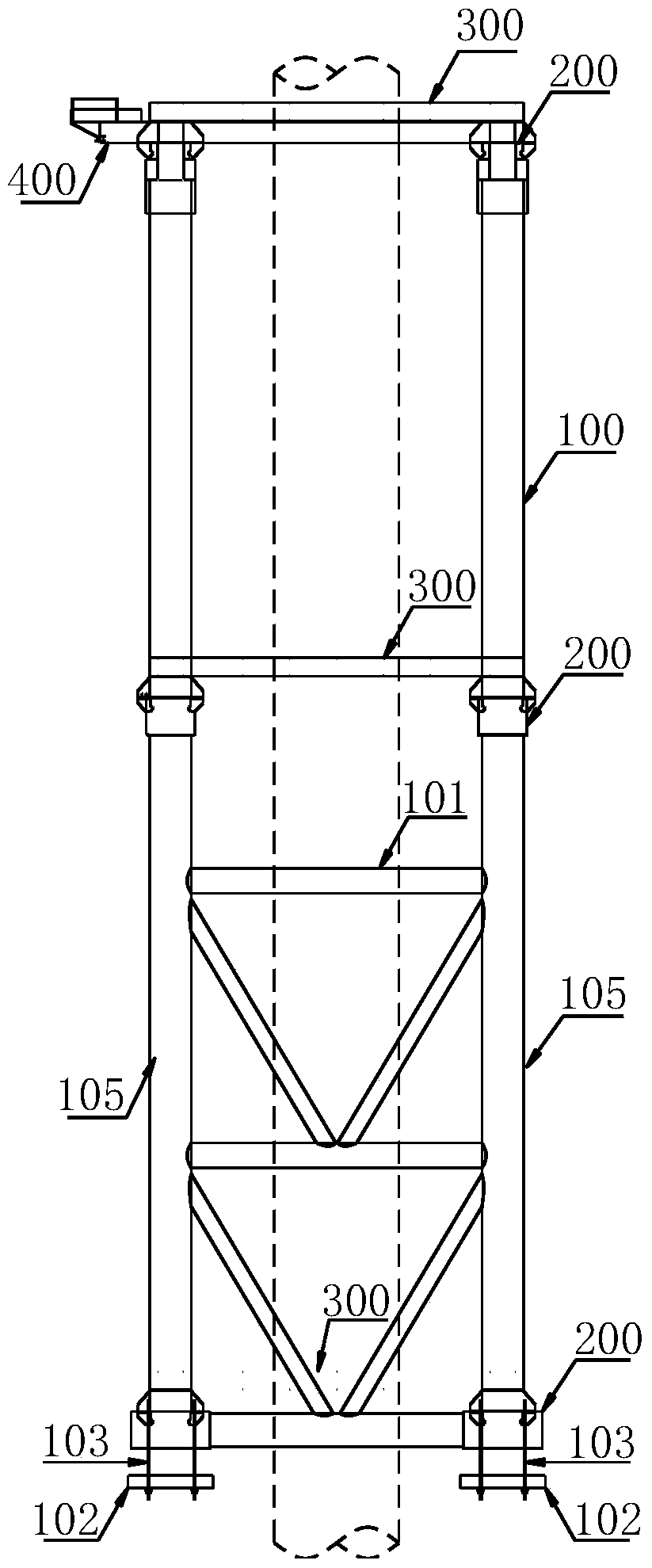

A multi-level guide bracket for oblique insertion and driving of ultra-long diameter piles

A guide bracket and large-diameter technology, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problem that the construction conditions for docking are not met, the guide bracket is difficult to meet the oblique insertion construction, and the guide bracket does not have horizontal force, etc. problems, to achieve a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

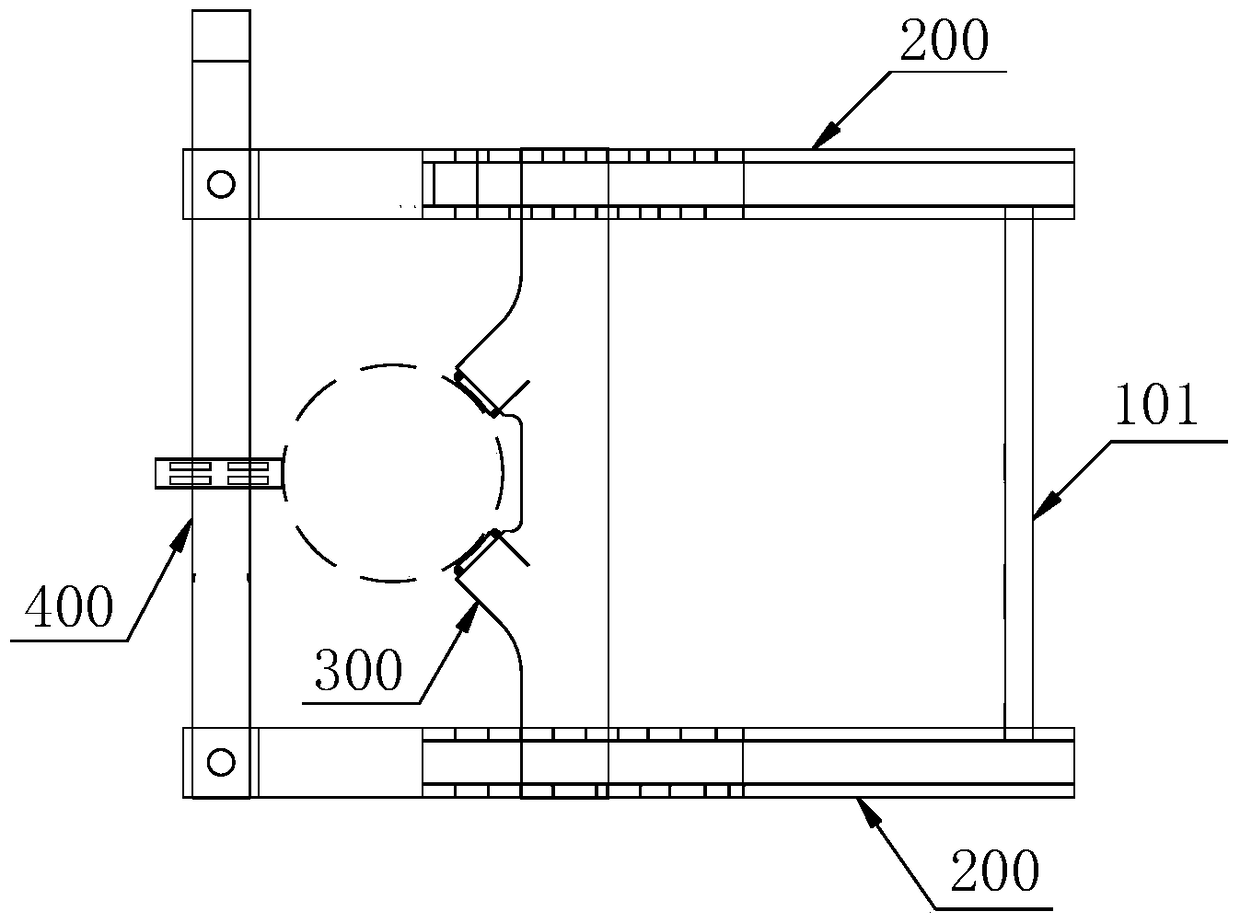

[0034] Use this super-long and large-diameter pile obliquely inserted multi-stage guide bracket to insert double-section precast piles or steel pipe piles. The inserting steps are described in detail below. For the convenience of description, the slideway at the top of the main truss 100 The support and guide member 300 on the beam 200 is named guide A, the support and guide member 300 on the slide beam 200 in the middle of the main truss 100 is named guide B, and the left and right supports on the slide beam 200 at the bottom of the main truss 100 The guide members 300 are named guide D and guide C, respectively.

[0035] First, fix the multi-level guide bracket for the oblique insertion of the super-long and large-diameter pile to the preset position of the pile, hoist the first section of the pile and insert it into the pile channel of the guide bracket. In the inclination adjusting device 400, guide A Under the joint action of, C and D, the pile is tilted according to the des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com