Temporary Anchorage System for Side Steel Box of Long-span Composite Beam Cable-Stayed Bridge

A large-span, steel box technology, applied in the direction of cable-stayed bridges, bridges, bridge forms, etc., can solve the problems of large-span cable-stayed bridge cantilever unbalanced force, unable to resist horizontal force, multiple steel strands, etc. , to achieve the effect of simple design and construction, good construction stability and low risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

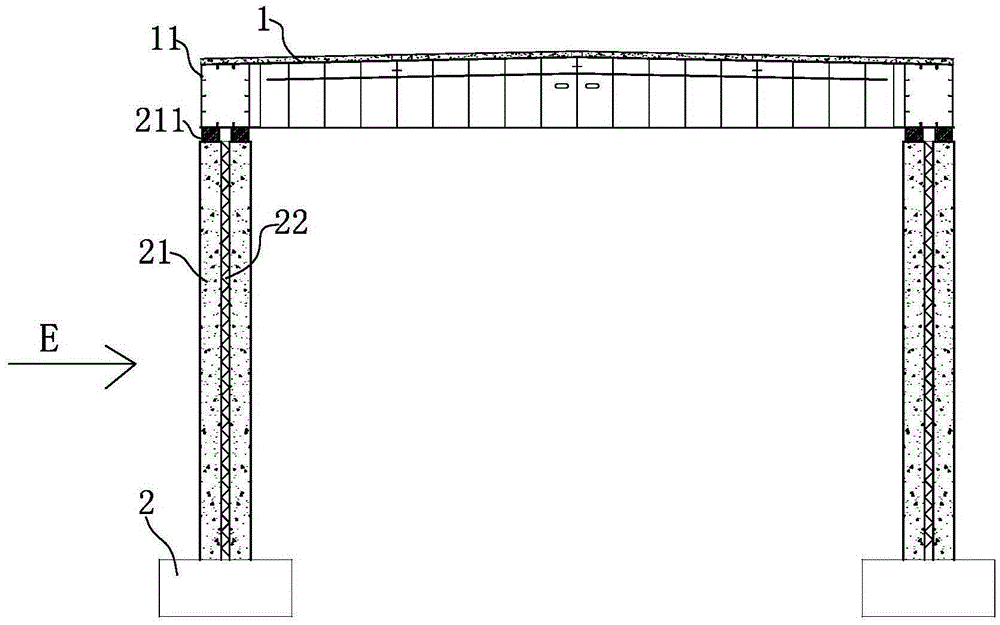

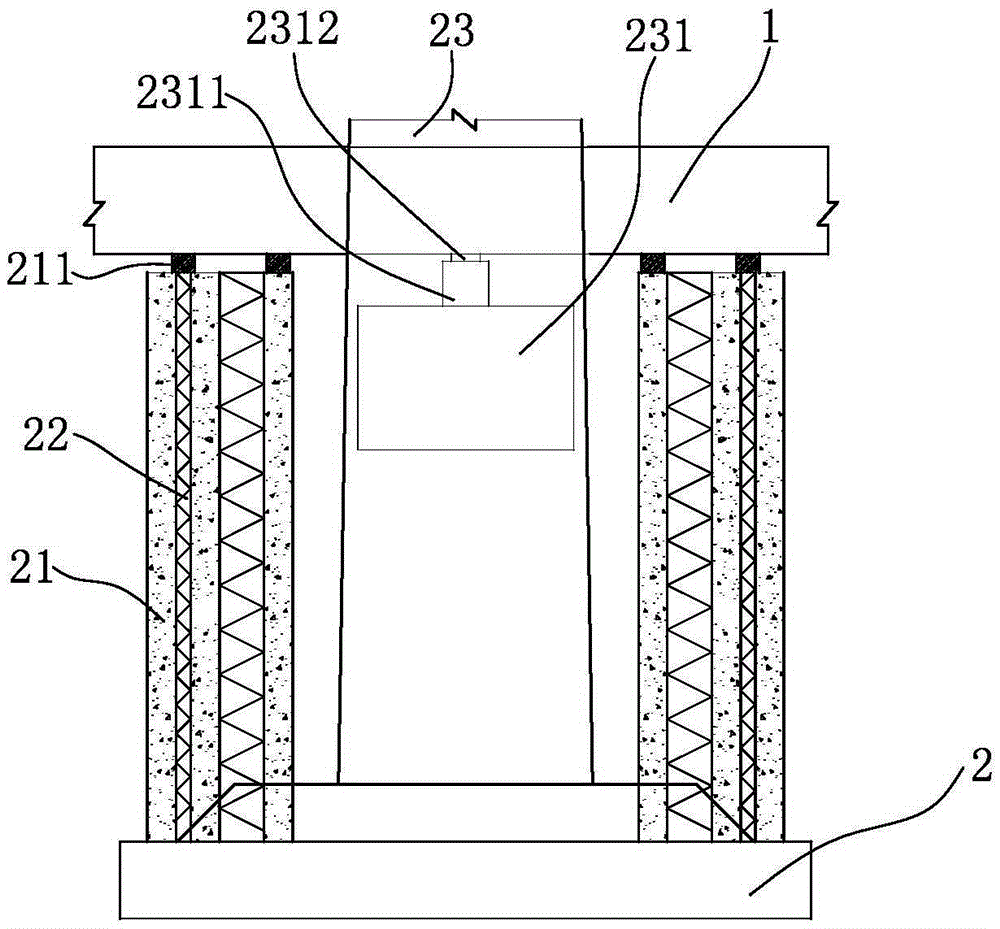

[0032] Such as figure 1 As shown, the main components of the cable-stayed bridge include a cable tower 23 and a box girder 1. There are generally two cable towers 23, which are mainly used for fixing the steel cables of the cable-stayed bridge. A cable tower beam 231 is arranged between the two cable towers 23, that is, the cable tower beam 231 connects the two cable towers 23 into an approximate A-shaped structure.

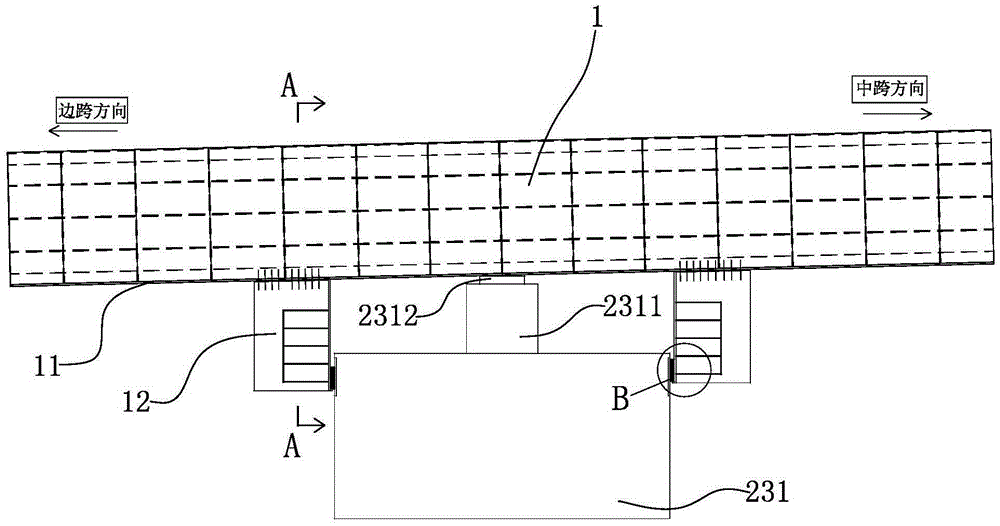

[0033] Such as figure 2 As shown, the upper end of the cable tower beam 231 is provided with a permanent support 2312, and a pad stone 2311 is arranged between the permanent support 2312 and the cable tower beam 231; The end face is used for laying the road surface, usually its two sides, that is, the two sides of the bridge are side steel boxes 11, which need to be fixedly arranged on the permanent support 2312 in the specific installation.

[0034] In the specific construction and installation process, when the box girder is constructed by the cantilever met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com