Magnetic levitation type portal crane device

A door machine and maglev technology, which is applied to the suspension device of the wing leaf, door/window accessories, power control mechanism, etc., can solve the problem that the strength is not enough to meet the support needs, the wear resistance cannot meet the long life requirements, and it is easy to deform and other problems to achieve the effect of reducing quality, preventing rust and corrosion, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

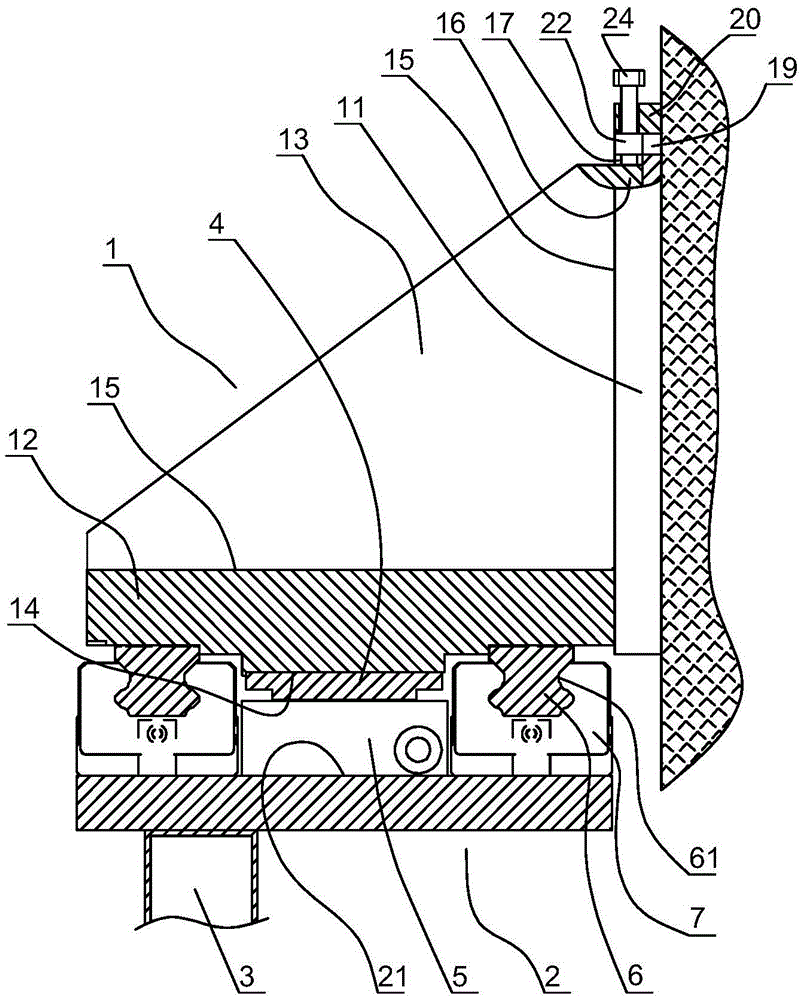

[0046] In this embodiment, the structure of the magnetic levitation door machine device is as follows: figure 1 as shown ( figure 1 is a section of the magnetic levitation door machine device, which is perpendicular to the moving direction of the mobile door), including a fixed support module 1 fixedly connected to the vertical wall, a mobile module 2 slidably connected to the fixed support module, and Mobile door 3 attached to the lower side of the mobile module.

[0047] The fixed support module includes an installation wallboard 11, a base plate 12 and several connecting plates 13 connecting the base plate and the installation wallboard. The installation wallboard is vertically arranged and fixedly connected with the wall. The base plate 12 is horizontally connected to the lower edge of the installation wall panel 11, so that the base plate 12 and the installation wall panel 11 form an L-shaped connection. Modular production, and simplify design, manufacture and maintenan...

Embodiment 2

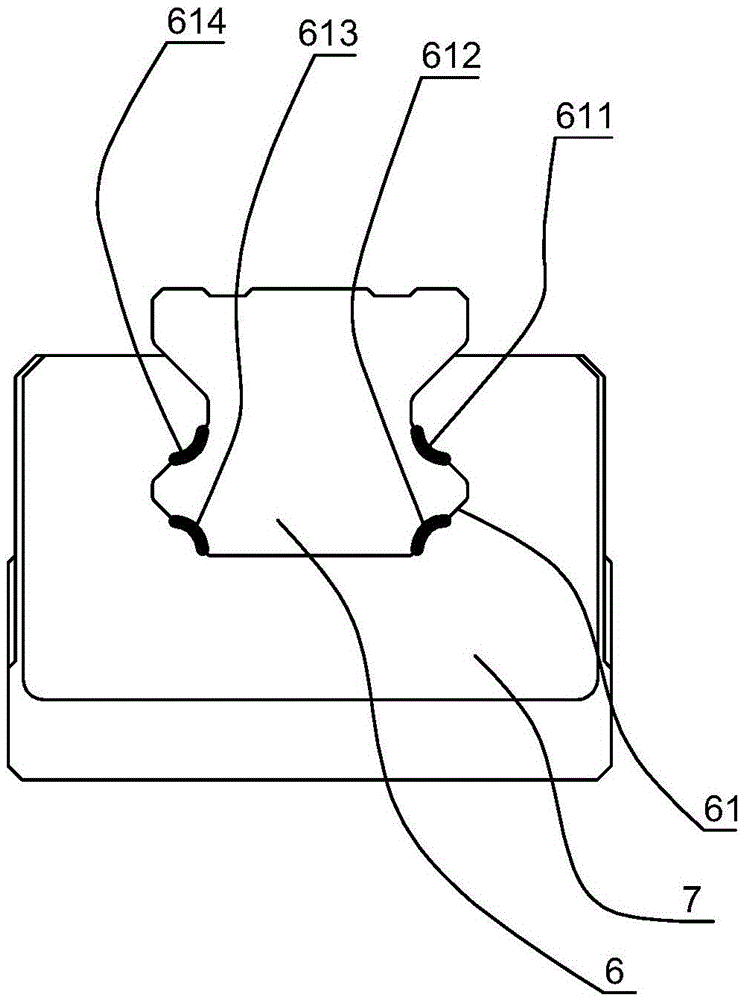

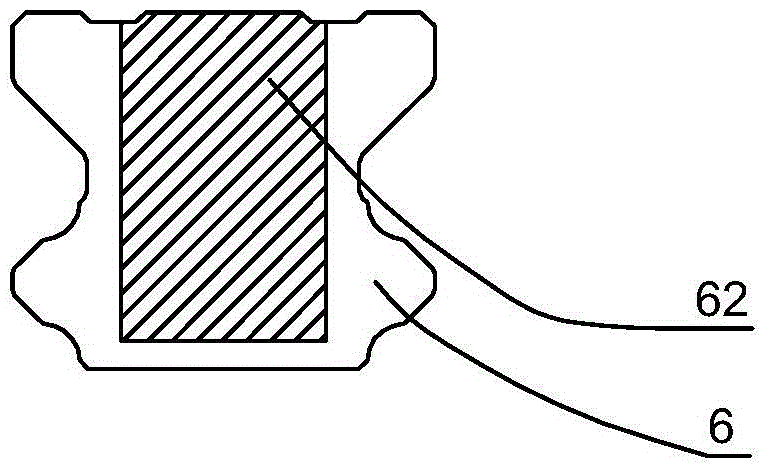

[0057] In this embodiment, the structure of the magnetic levitation door machine device is basically the same as that in Embodiment 1, the difference is that the structure of the guide rail is as follows: Figure 7 As shown, the guide rail is provided with six guide rail working surfaces to match it, and the slider is provided with six slider working surfaces. The paired guide rail working surfaces match the shape of the slider working surface. When the slider slides guided by the guide rail, it passes The working surfaces of the paired guide rails are in contact with the working surfaces of the slider to form six contact working surfaces 611 , 612 , 613 , 614 , 615 and 616 , so as to provide limit in the up-down direction and limit in the left-right direction. The material of the working surface of each guide rail is polyether ether ketone plastic, and the material of the working surface of each slider is polyether ether ketone plastic. Such as Figure 7 As shown, the six wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com