Archimedes double-helix split-type double-cluster hydraulic jet fracturing integrated string

A technology of hydraulic jet and hydraulic jet, which is applied in the direction of production fluid, wellbore/well components, earth-moving drilling, etc., to achieve the effect of improving the effect and preventing local erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

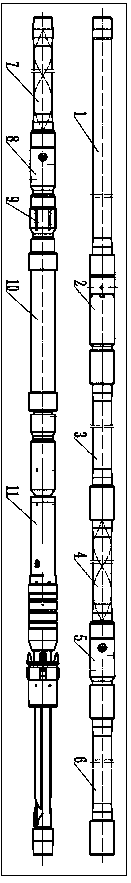

[0025] The present invention provides as figure 1 , figure 2 , image 3 , Figure 4 As shown in the Archimedes double-helix split-flow dual-cluster hydraulic jet fracturing integrated pipe string, the present invention uses the Archimedes double-helix structure to change the oil pipe in front of the upstream and downstream injectors of the conventional hydraulic jet fracturing string The flow state and flow direction of the fluid inside and inside the upstream and downstream injectors solves the problem of particle sand concentration, flow, and pressure balance between the upper and downstream injectors of the dual-cluster hydraulic jet fracturing string dragged by the bottom seal, effectively preventing The double-cluster hydrojet fracturing string with bottom seal is damaged due to the erosion of the upper and lower injectors in different degrees, so as to avoid the entire double-cluster hydraulic jet fracturing string with bottom seal. Therefore, it is completely invali...

Embodiment 2

[0041] Based on Embodiment 1, in this embodiment, the oil pipe 1 is connected to the first adjusting nipple 3 through a safety joint 2 .

[0042] The oil pipe 1 is a Φ73mm oil pipe.

[0043] Both the first adjusting short joint 3 and the second adjusting short joint 6 are Φ73mm adjusting short joints.

[0044] The first Archimedes double-helix split-flow hydraulic jet 5 has the same structure as the second Archimedes double-helix split-flow hydraulic jet 8 , with a length of 370 mm, an outer diameter of 100 mm, and an inner diameter of 32 mm.

[0045] The first Archimedes double helix shunt joint 4 has the same structure as the second Archimedes double helix shunt joint 7, with a length of 2500 mm, an outer diameter of 90 mm, and an inner diameter of 32 mm.

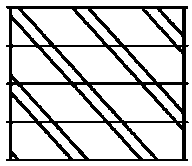

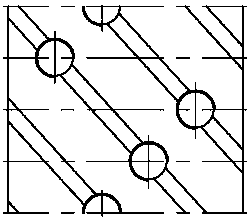

[0046] The first Archimedes double helix diverter nipple 4 and the first Archimedes double helix diverter hydraulic injector 5 both have the Archimedes double helix in the inner cavity clockwise, with a helix angle of 45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com