A wheel hub oil pump mechanism

A technology of wheel hub and oil pump, applied in the direction of mechanical equipment, slack adjuster, brake type, etc., can solve the problem that oil-cooled disc brake cannot be implemented.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

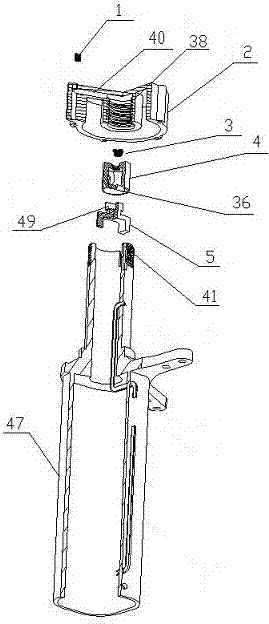

[0016] Such as figure 1 The hub oil pumping mechanism shown includes a hub (not shown) that is rotatably connected to the axle housing 47, the hub is connected with the axle head cover 2, and also includes a drive block 5 connected to the end of the axle housing 47, The screw oil groove 38 connected to the shaft head cover 2, and the shaft head cover core 4 whose one end is connected to the drive block 5 and the other end is inserted into the screw oil groove 38, there is a gap between the shaft head cover core 4 and the screw oil groove 38, and the screw head The inner wall of the oil groove 38 is provided with threads opposite to the rotation direction of the hub, and the shaft head cover 2 is also provided with an oil passage 40 whose oil inlet is located in the helical oil groove 38 . The driving block 5 is composed of a center column, pins vertically extending from both ends of the center column to one side, and a protrusion extending vertically from the middle of the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com