Underground gravity heat pipe direct heating device

A gravity heat pipe and heating device technology, applied in the field of heating devices, to achieve the effect of no operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

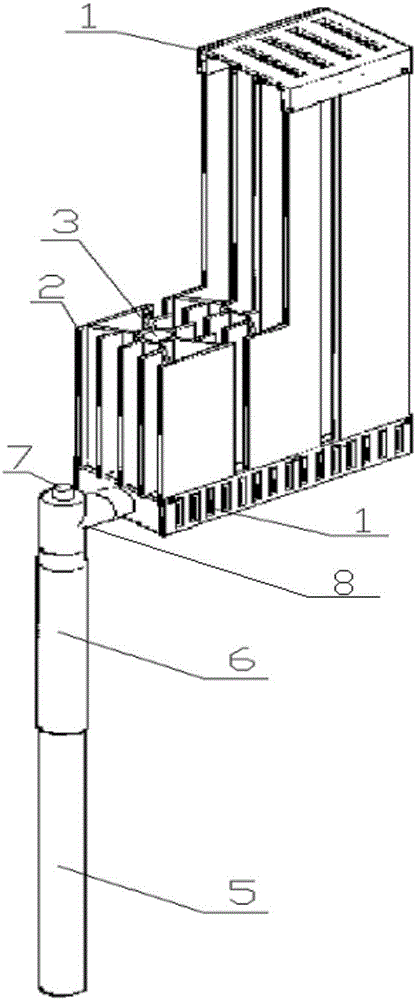

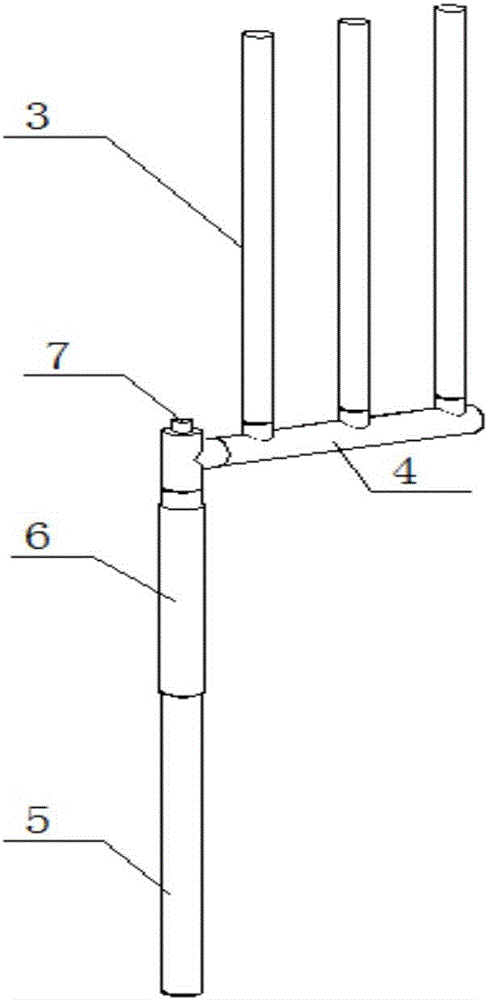

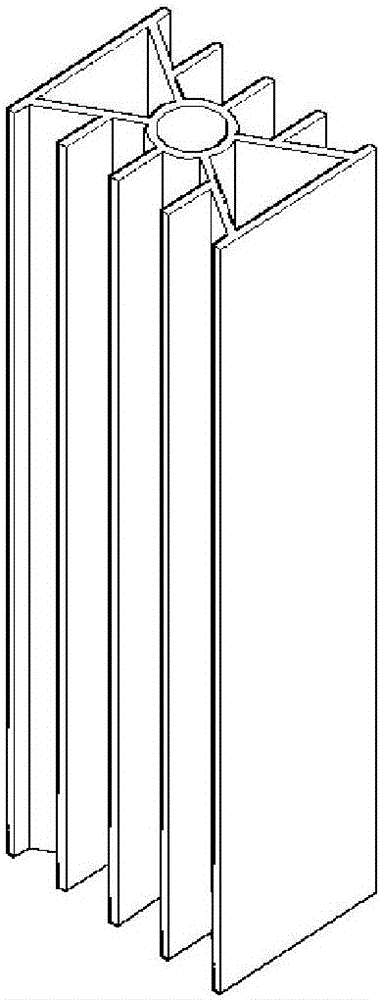

[0021] Such as figure 1 As shown, the heating device includes a heat absorbing section 5 of a gravity heat pipe, an adiabatic section 6 of a gravity heat pipe, a decorative protective cover 1, an aluminum airfoil heat sink 2, a cooling branch pipe 3, a horizontal main pipe 4 and a liquid filling port 7; The decorative protective cover 1 is screwed on the aluminum airfoil heat sink 2; the aluminum airfoil heat sink 2 is connected to the heat dissipation branch pipe 3 by expansion; the heat dissipation branch pipe 3 and the horizontal main pipe 4 are connected by welding; the horizontal main pipe 4 is connected by The tee 8 is connected to the heat insulation section 6 of the gravity heat pipe; the liquid filling port 7 is welded to the end of the tee 8 which is not connected. The heat-absorbing section 5 and the heat-insulating section 6 are vertically placed in the soil, wherein the heat-absorbing section 5 is placed at a depth of 10m-15m in the soil constant temperature layer...

Embodiment 2

[0023] Such as Figure 4 As shown, in this embodiment, the decorative protective cover 1 is removed, and a pair of face-to-face heat dissipation aluminum plates 9 are used to replace the aluminum airfoil heat sink 2, and a strip-shaped slot is left on the heat dissipation plate, and the gravity heat pipe buried in the ground The heat dissipation branch pipe 3 is embedded in the groove, and the heat dissipation plates 8 arranged face to face are fixed by screw connection. Other positions are similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com