Cam constant force mechanism

A cam mechanism, cam technology, applied in mechanical equipment, belts/chains/gears, transmissions, etc., can solve the problems of low reliability, complex structure, large volume, etc., achieve simple principle and structure, compact structure, reliable high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

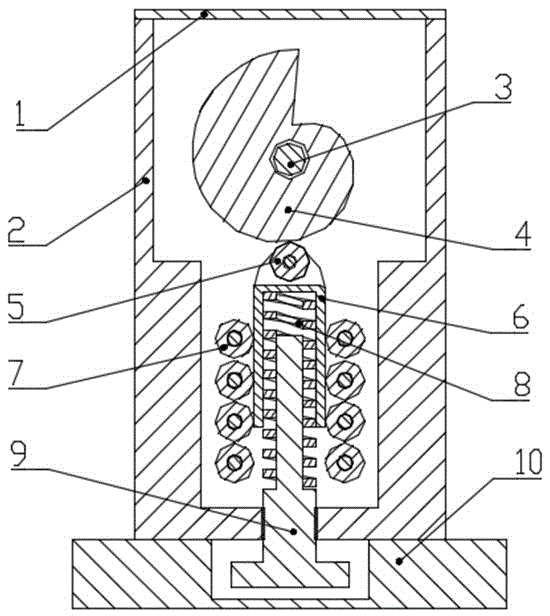

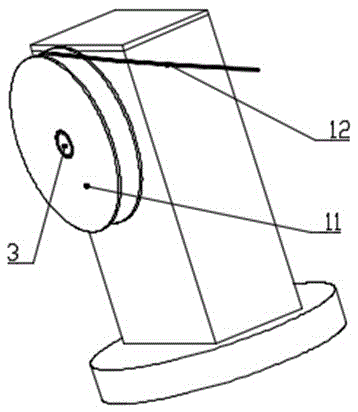

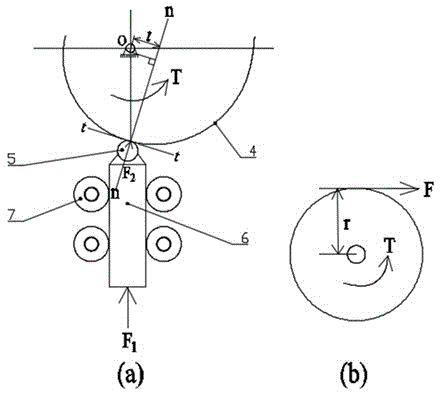

[0017] like figure 1 As shown, the cam constant force mechanism described in this embodiment includes a base and a cam mechanism: the base is composed of a cover plate 1, a housing 2 and a chassis 10; the cover plate 1, the housing 2 and the chassis 10 are fixed in sequence; the cam mechanism It is composed of screw 9, spring 8, push rod 6, roller 5 and cam 4; the screw 9, spring 8, and push rod 6 are connected in sequence, the screw 9 is screwed with the bottom of the shell 2, and the cam 4 is connected with the camshaft 3 is fixedly connected and installed inside the housing 2, the roller 5 is installed on the top of the push rod 6 and is in contact with the cam 4; the inside of the housing 2 is also equipped with a bearing 7, and the bearing 7 is centered on the push rod 6 to work on the cam 4 They are arranged symmetrically on the plane, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com