Improved split faucet

An improved faucet technology, which is applied in the field of faucets, can solve problems such as freezing cracks, difficulty in locking nuts, and cracks, and achieve the effects of preventing expansion and shrinkage, increasing connection stability, and convenient installation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

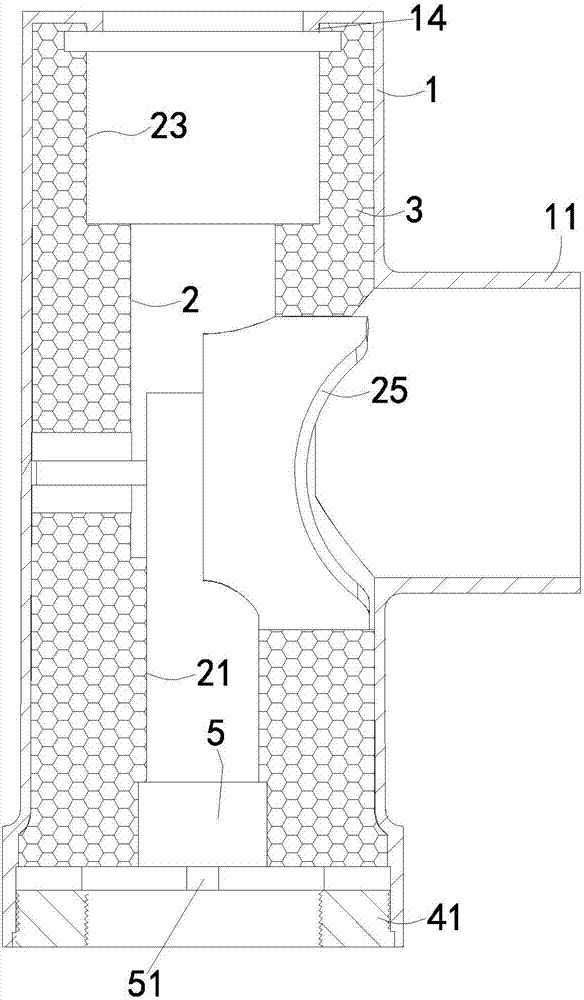

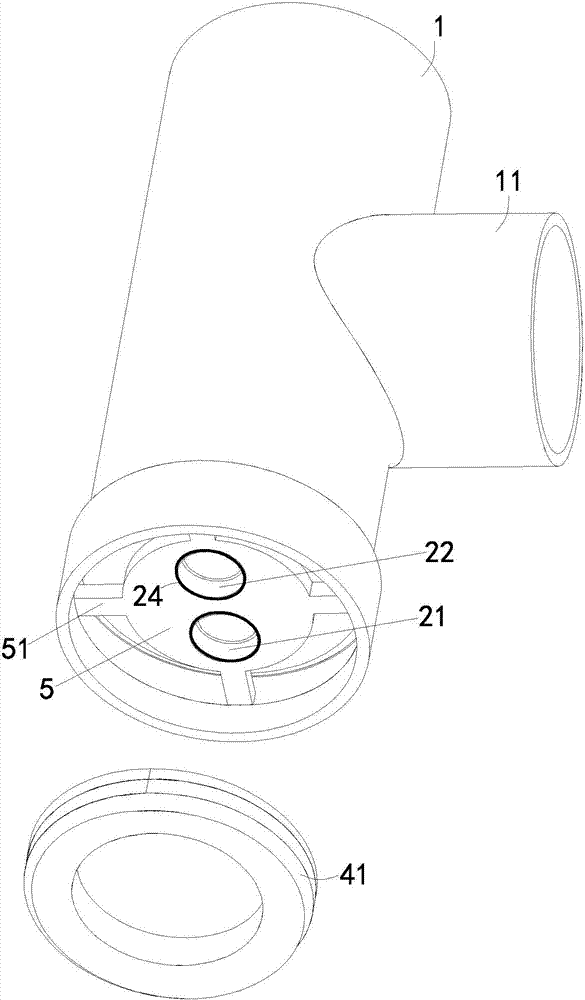

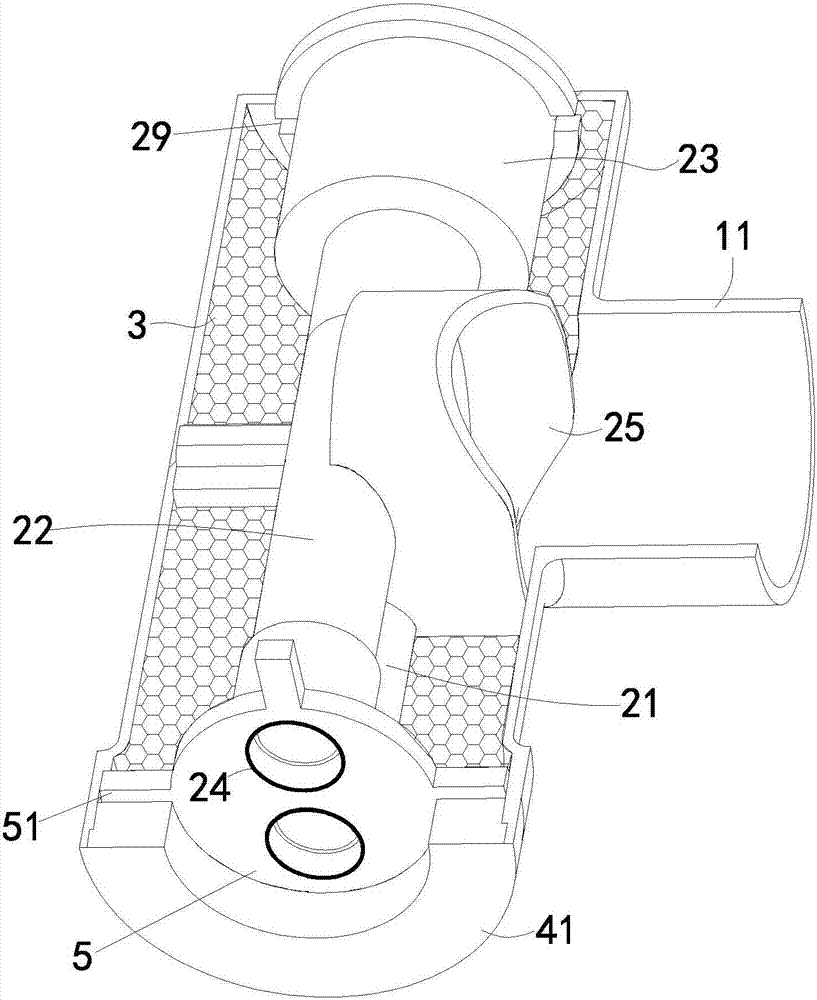

[0030] Such as Figure 1 to Figure 4 , the embodiment of the present invention discloses an improved split faucet, including a zinc alloy faucet body 1 and a plastic inner valve core tube 2 disposed in the zinc alloy faucet body 1, and the plastic inner valve core tube 2 can be pc polycarbonate or pp polypropylene or POM polyoxymethylene plastic inner valve core tube, in this embodiment, pc polycarbonate plastic inner valve core tube is used, the zinc alloy faucet body 1 has a hollow inner cavity, and one side of the middle part of the zinc alloy faucet body 1 A spool installation pipe 11 is provided, and the plastic inner spool pipe 2 is provided with a water inlet pipe and an outlet pipe 23 along the axial direction, and the water inlet pipe includes a cold water inlet pipe 21 and a hot water inlet pipe 22, and the cold water inlet pipe and the The inner cavity at the bottom of the hot water inlet pipe is provided with a copper sleeve 24, and the inner wall of the copper sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com