cooling system

A cooling system and cooling unit technology, applied in the field of metallurgy, can solve the problems of large water flow resistance and safety hazards, and achieve the effects of reducing liquid flow resistance, safety hazards, and safety production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other if there is no conflict. Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

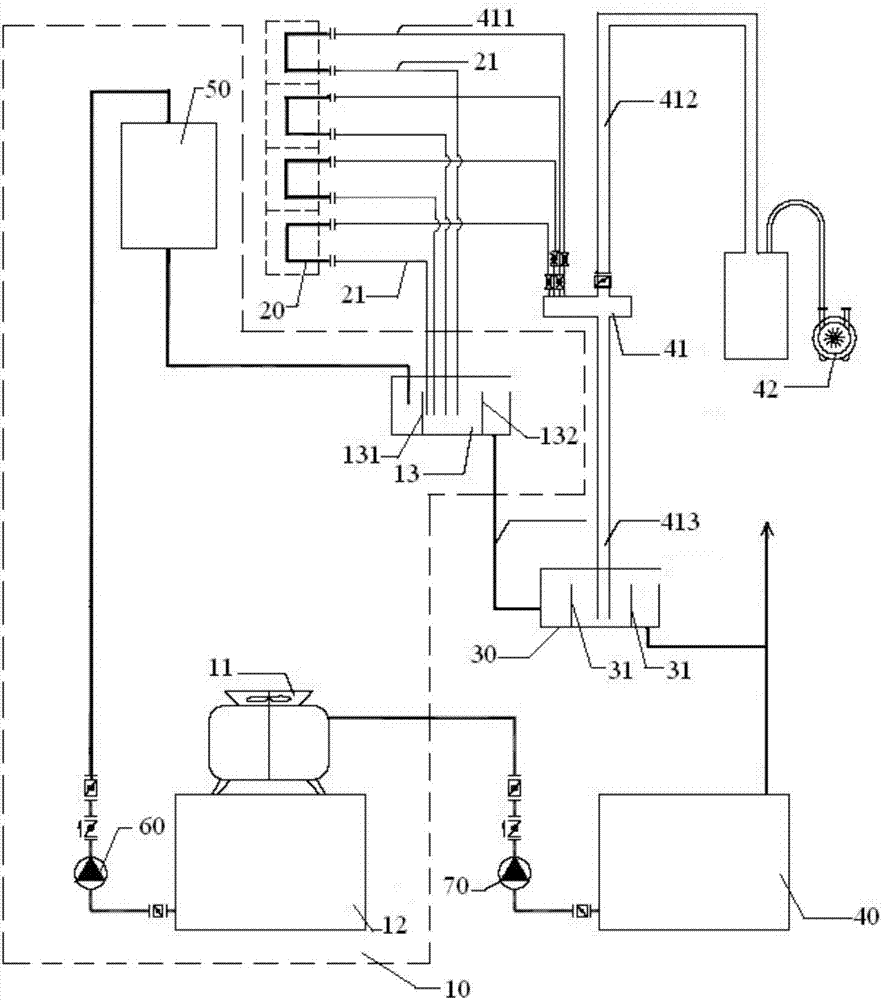

[0022] As described in the background art, the existing positive pressure cooling has the problems of large water flow resistance and high safety risks. In order to solve the above technical problems, the present invention provides a cooling system, such as figure 1 As shown, the cooling system includes: a refrigerant supply unit 10, a cooling unit 20 for cooling an object to be cooled, a liquid sealing tank 30, and a refrigerant recovery unit 40. The cooling unit 20 and the refrigerant supply unit 10 are connected through a refrigerant input pipe 21; the refrigerant recovery unit 40 includes a refrigerant recovery pipe group 41 and a vacuum pump group 42. The refrigerant recovery pipe g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com