A charging system for advanced rock breaking in open-pit mines

A charging system and advanced technology, applied in blasting and other directions, can solve problems such as affecting the economic benefits of mines and production safety, increasing ore mining costs, affecting production efficiency, etc., so as to improve the full load factor and utilization rate, and reduce the production cost of raw ore. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further describe the present invention, a charge system for advanced rock breaking in open-pit mines of the present invention will be further described below in conjunction with the accompanying drawings and examples.

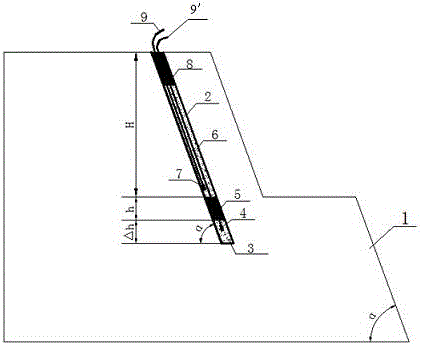

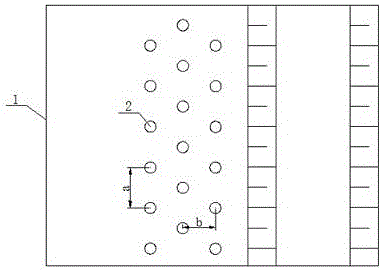

[0027] Depend on figure 1 Shown the present invention a kind of open-pit mine advanced rock-breaking charge system longitudinal sectional view and combines figure 2 It can be seen that a kind of charging system for advanced rock breaking in an open-pit mine of the present invention, first on the pre-blasting open-air step 1, the blastholes are arranged according to the designed blasthole hole network parameters-blasthole hole distance a, blast hole row distance b 2. Form a blast hole network. The blast hole depth L of the blast hole 2 is designed according to the following formula: L=H / sin α'+h / sin α'+△h / sin α', where: L—blast hole depth, H—open-air step Height, h—extra-deep blasthole, △h—deepening blasthole, α’—inclination angle of blasth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com