Coupling alignment scheme for rabbet-matched single-fulcrum shafting steam turbines

A single fulcrum, steam turbine technology, applied in the direction of instruments, mechanical devices, mechanical measuring devices, etc., can solve the problems of false tile stability affecting shaft alignment, etc., and achieve the effect of simple alignment process, consistent state, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the drawings and embodiments.

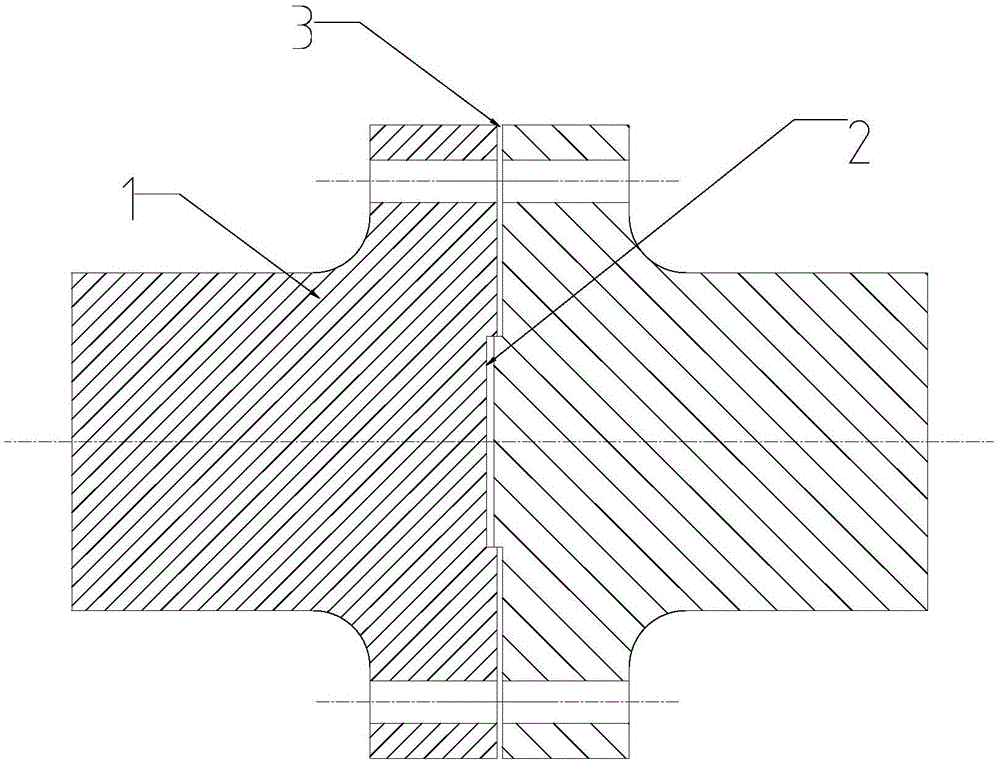

[0031] Such as figure 1 As shown, the single fulcrum shafting steam turbine coupling 1 has a deep stop 2, and the depth of the stop 2 is generally 10-12 mm.

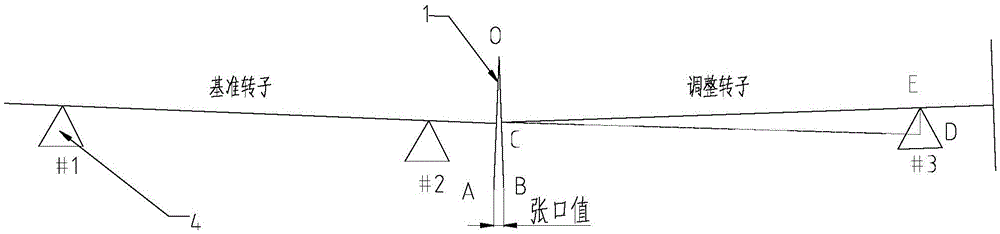

[0032] Relying on the structural characteristics of the steam turbine coupling, the single fulcrum shafting coupling is usually designed as a concave-convex spigot clearance fit, and the clearance of the spigot fit is 0.03-0.05mm. The standard requirement for the alignment of the steam turbine rotor coupling is the deviation of the circle center. Not more than 0.03mm. Combining this feature, when aligning the adjacent rotor couplings, first pull the two rotor couplings with four temporary bolts (the temporary bolts are pin bolts whose diameter is smaller than the coupling bolt by 0.20mm). Together, the two coupling ends are matched and connected to eliminate the deviation of the circumference. The depth of the stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com