Video data mining-based non-contact object vibration frequency measurement method

A technology of vibration frequency and video data, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of high cost, complex technology, and the inability to install vibration sensors on the measured object, so as to achieve simple equipment and adaptability Good, cheap to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

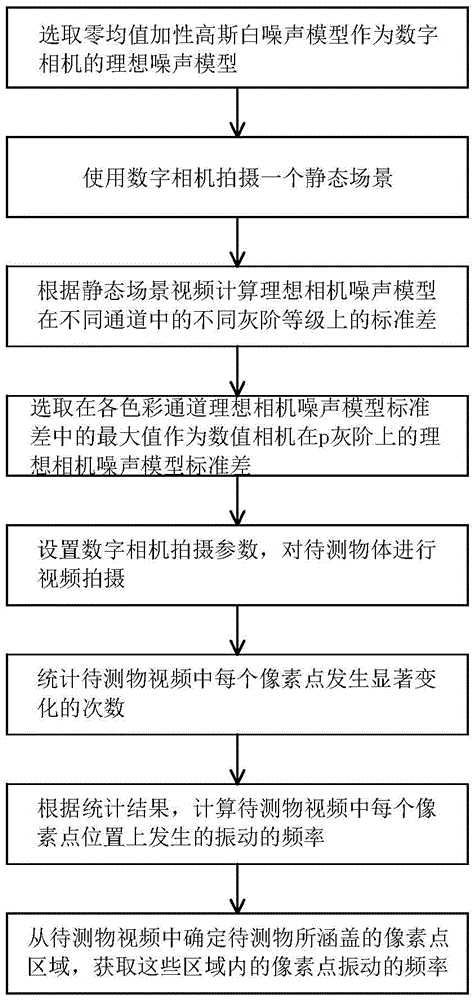

[0049] In this embodiment, a method for measuring the vibration frequency of a non-contact object based on video data mining, such as figure 1 shown, including the following steps:

[0050] S1. Construct the ideal camera noise model of the digital camera used;

[0051] The construction steps specifically include:

[0052] S11. Select the zero-mean additive Gaussian white noise model as the ideal noise model of the digital camera used; the zero-mean additive Gaussian white noise model assumes that the amplitude of the ideal camera noise at each pixel follows a Gaussian distribution with a mean value of zero .

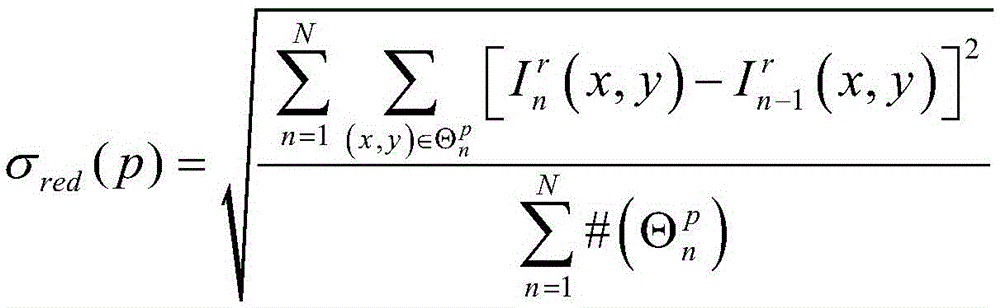

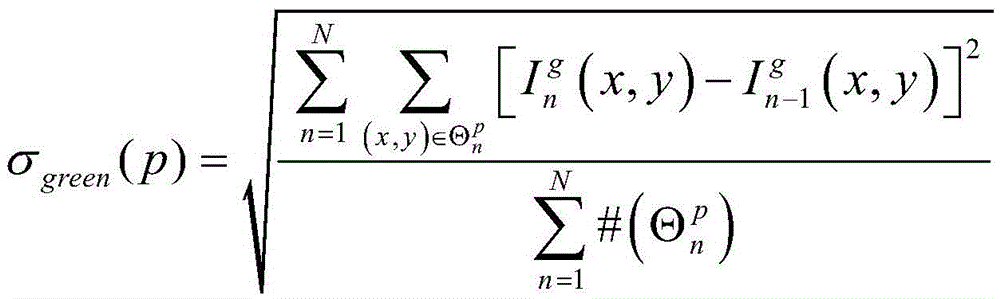

[0053] S12. Calculate the standard deviation of the Gaussian noise distribution of the selected ideal noise model. The standard deviation of the Gaussian noise distribution of the ideal noise model is the only unknown parameter of the ideal noise model. The ideal camera noise model of the digital camera used is thus constructed, which obeys the Gaussian distribution....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com