Torsional strength testing torsion testing machine

A torsion testing machine and torsional strength technology, applied in the field of testing machines, can solve the problems of claw damage, inaccurate positioning, uneven force on the guide rail, etc., to avoid damage, uniform feeding speed, and accurate data results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

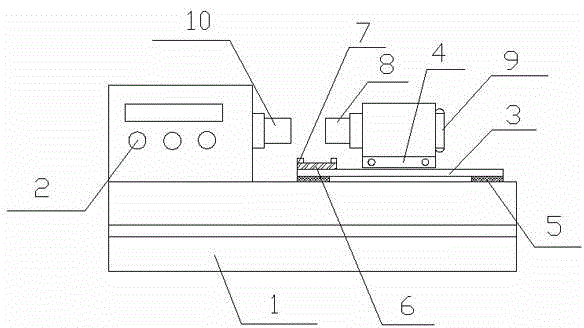

[0011] A torsion testing machine for torsional strength testing, comprising a frame 1 and an operating table 2, the frame 1 is provided with an operating table 2, the frame 1 is provided with a guide rail 3, and the guide rail 3 is provided with a test operating table 4, the test The operating table 4 is provided with an operating rod and an emergency stop part, and an opening and closing rod is provided beside the operating rod. A positioning block 5 is provided between the test operating table 4 and the guide rail 3, and the positioning block 5 is located at the bottom of the test operating table 4. The block 5 is made of alloy steel. The top of the guide rail 3 is provided with a baffle 6. The baffle 6 is a rectangular structure. 12cm, the operation test bench 4 is provided with a clamping mechanism 8, the clamping mechanism 8 is a claw, the claw is connected with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com