Loadable device for similarity simulation test and use method thereof

A test device and similar simulation technology, applied in the field of loadable similar simulation test devices, can solve the problems of inability to simulate vertical and horizontal stress, inability to realize controllable pressurization, inconvenient operation, etc., and achieve simple and controllable pouring process , simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

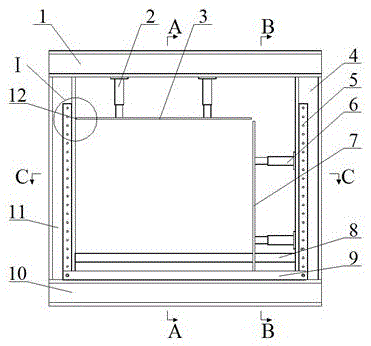

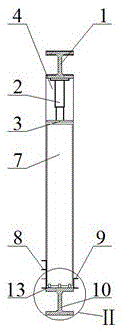

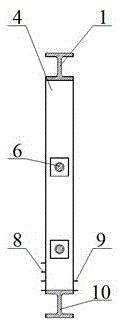

[0027] A loadable similar simulation test device. like figure 1 , figure 2 , image 3 and Figure 4 As shown, the loadable similar simulation test device is composed of a frame and a loading device.

[0028] The structure of the framework is as figure 1 , figure 2 , image 3 and Figure 4 As shown: the upper beam 1, the lower beam 10, the left column 11 and the right column 4 are connected to form a rectangular frame, and the rectangular frame is H-shaped steel. Two angle steels 5 are symmetrically fixed on the inner side panels of the left column 11 and the right column 4, such as Figure 7 As shown, one side of the two angle steels 5 is symmetrically fixed on both sides of the webs of the respective inner flanges, and the other side of the two angle steels 5 is symmetrically processed with bolt holes, and the other side of the two angle steels 5 is symmetrically fixed to the respective inner flanges. The edges of the side panels are flush. like figure 1 As shown...

Embodiment 2

[0037] A loadable similar simulation test device. Except following technical parameter, all the other are with embodiment 1:

[0038] The widths of the upper pressure plate 3 and the right pressure plate 7 are equal, and the width is smaller than the distance between the front side baffle 9 and the rear side baffle 8 on the front and rear sides of the rectangular frame, and the difference between the two is 6-8mm .

[0039] Compared with the prior art, this specific embodiment has the following positive effects:

[0040] The frame of this specific embodiment is composed of H-shaped steel, channel steel and angle steel 5, and the loading device is only composed of two pairs of hydraulic jacks and corresponding pressure plates, with simple structure and low manufacturing cost. At the same time, the pouring area of the similar model is smaller, and the manufacturing cost of the similar model is lower.

[0041] In this specific embodiment, in the similar simulation of deep ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com