Member for electrophotography, process cartridge and image forming apparatus

A technology for electrophotography and charging member, which is applied to the equipment of the electric recording process applying the charge pattern, the electric recording process applying the electric charge pattern, the electrical components and other directions, and can solve the problems of reducing the effect of reducing the adhesion of dirt and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107]

[0108] The kinds and amounts of each material shown in Table 1 were mixed using a pressure kneader to obtain a kneaded rubber composition A. Further, 183.0 parts by mass of the kneaded rubber composition A was mixed with the kinds and amounts of each material shown in Table 2 below using an open mill to obtain an unvulcanized rubber composition.

[0109] Table 1

[0110]

[0111] Table 2

[0112]

[0113]

[0114] A cylindrical steel substrate (having a nickel-plated surface) with a diameter of 6 mm and a length of 252.5 mm was coated with a thermosetting adhesive (Metalock N-33, manufactured by ToyoKagaku Kenkyusho Co., Ltd.). The resultant was dried at 80° C. for 30 minutes, and then further dried at 120° C. for 1 hour.

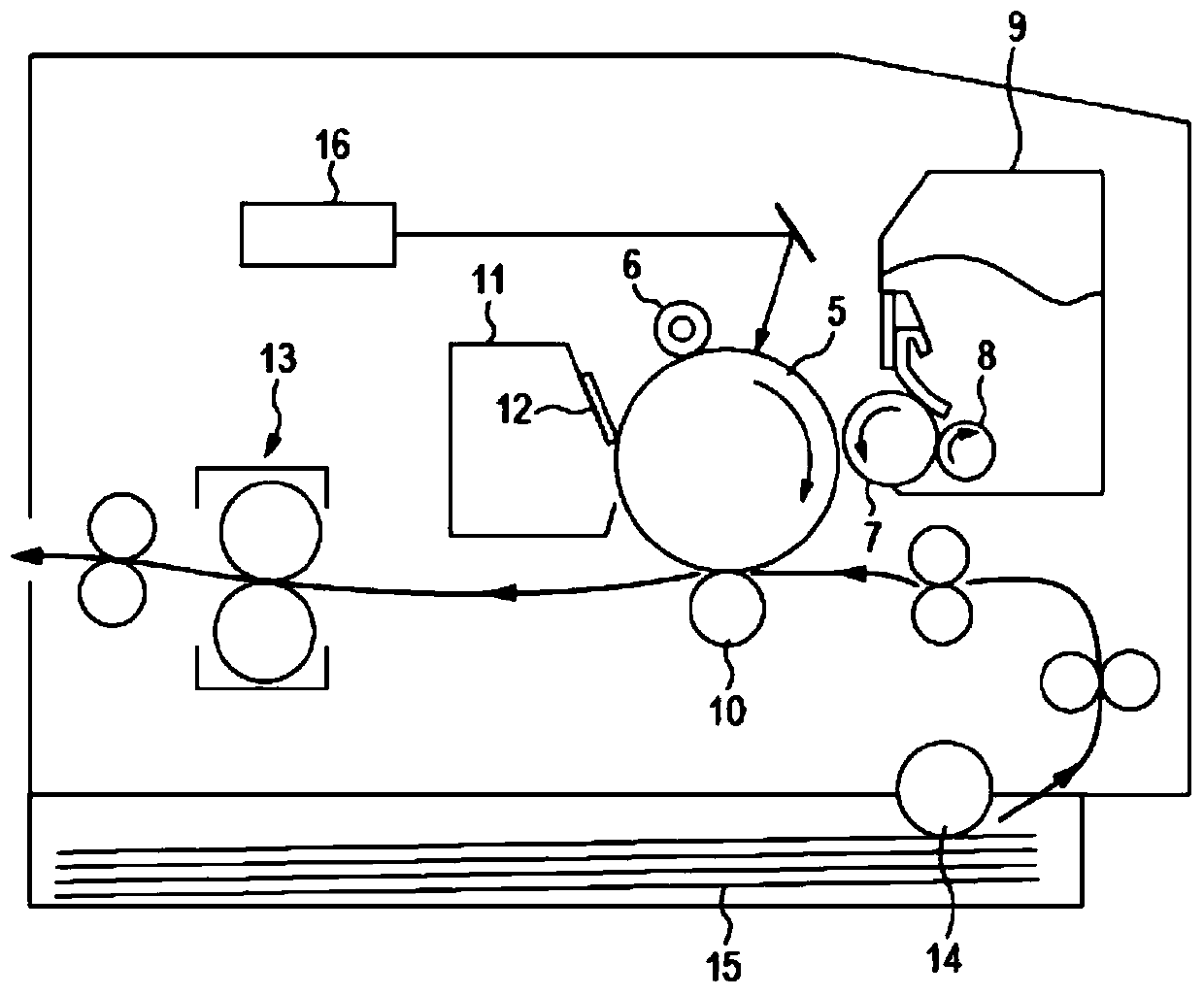

[0115] Next, the unvulcanized rubber composition was coaxially extruded on the substrate into a cylindrical shape with an outer diameter of 8.75 to 8.90 mm using a crosshead extruder to obtain an unvulcanized rubber member. Subsequentl...

Embodiment 2 to 37

[0186]

[0187] Coating liquids 2 to 33 were prepared in the same manner as in coating liquid 1 except that the composition was changed as shown in Tables 3-1 to 3-4. The kinds of the following components (A) to (E) described in Tables 3-1 to 3-4 are shown in Table 4.

[0188] (A) polyol (hydroxyl-terminated prepolymer),

[0189] (B) Isocyanate (isocyanate-terminated prepolymer),

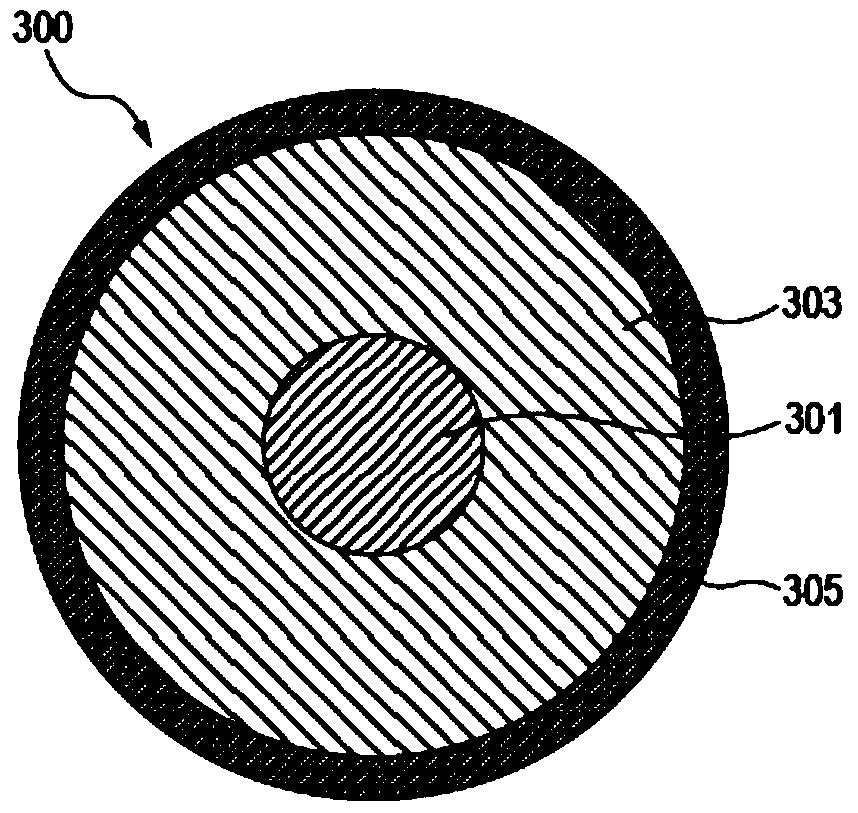

[0190] (C) second particles,

[0191] (D) silicone additives, and

[0192] (E) First particle

[0193] Prepared in the same manner as in Example 1 by adjusting the isocyanate group content to 4.3% by mass by means of a preliminary reaction between polyol and polymerized MDI (trade name: Millionate MR 200, manufactured by Tosoh Corporation) Using isocyanate group-terminated prepolymerization some parts of things.

[0194]

[0195] Members 2 to 37 for electrophotography were produced and evaluated in the same manner as in Example 1 except that the coating liquid used in the surface layer form...

Embodiment 38

[0208] Members for electrophotography were produced and evaluated in the same manner as in Example 1, except that the materials described in Table 5 were used instead of Epichlomer CG-102 (also referred to as CG 102) in the preparation of the kneaded rubber composition A 38. The evaluation results are shown in Table 9-6.

[0209] table 5

[0210]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com