Pneumatic type precise corn no-tillage planter

A pneumatic, seeder technology, applied in the directions of seeder parts, seeding, fertilizer and seeding equipment, etc., can solve the problems of spring adjustment and lower limit, give a reasonable solution, seeder damage, easy congestion and other problems, to ensure seeding. The effect of deep consistency, smooth work and stable contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0110] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

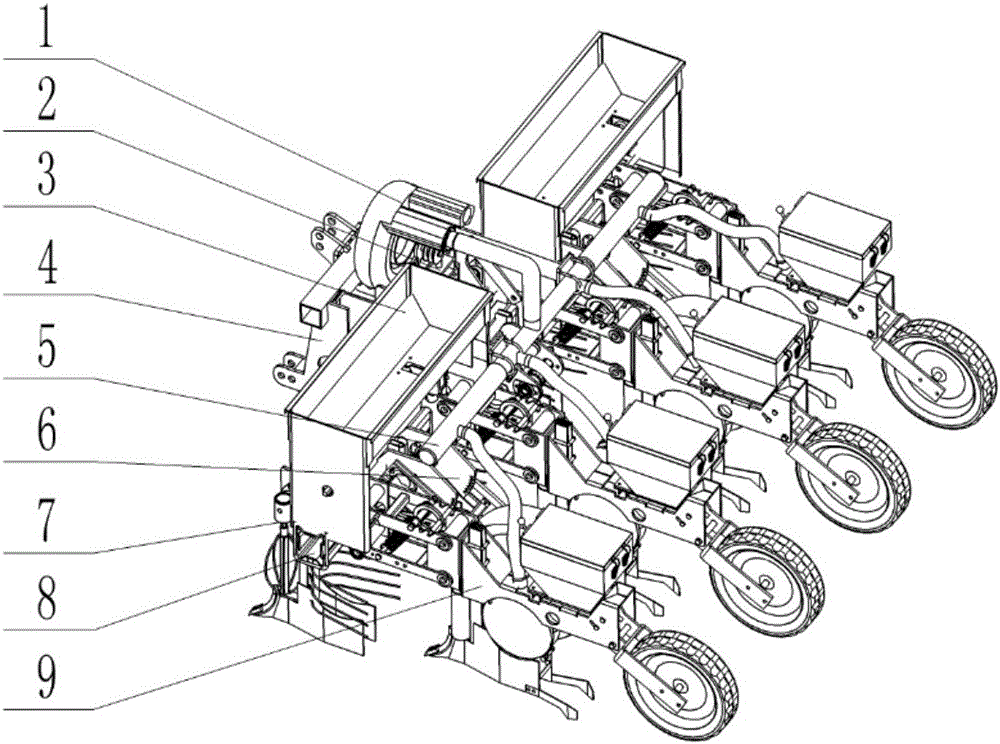

[0111] Such as figure 1 As shown, a pneumatic corn precision no-tillage seeder includes fan 1, fan rack 2, fertilizer box 3, three-point suspension mechanism 4, air pressure distribution pipe 5, depth limiting mechanism 6, and active anti-blocking mechanism 7 , universal frame 8 and parallel four-bar linkage seeding mechanism 9.

[0112] The general-purpose frame 8 is a hollow beam, the middle part of the front end of the beam is connected with a three-point suspension mechanism 4, a plurality of active anti-blocking mechanisms 7 are connected under the front end, and a plurality of parallel four-bar linkage seeding mechanisms 9 and depth-limiting mechanisms are connected under the rear end of the beam. 6, and the active anti-blocking mechanism 7 and the parallel four-bar linkage seeding mechanism 9 are arranged in a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com