Ventilation wind network system for steel plate warehouses

A technology of steel silo and wind net, applied in fruit hanging device, botanical equipment and method, horticulture, etc., can solve the problems of pollution of workplace and outdoor environment, production and environmental hazards, deterioration of grain quality, etc., to improve filling Efficiency, labor saving, and the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

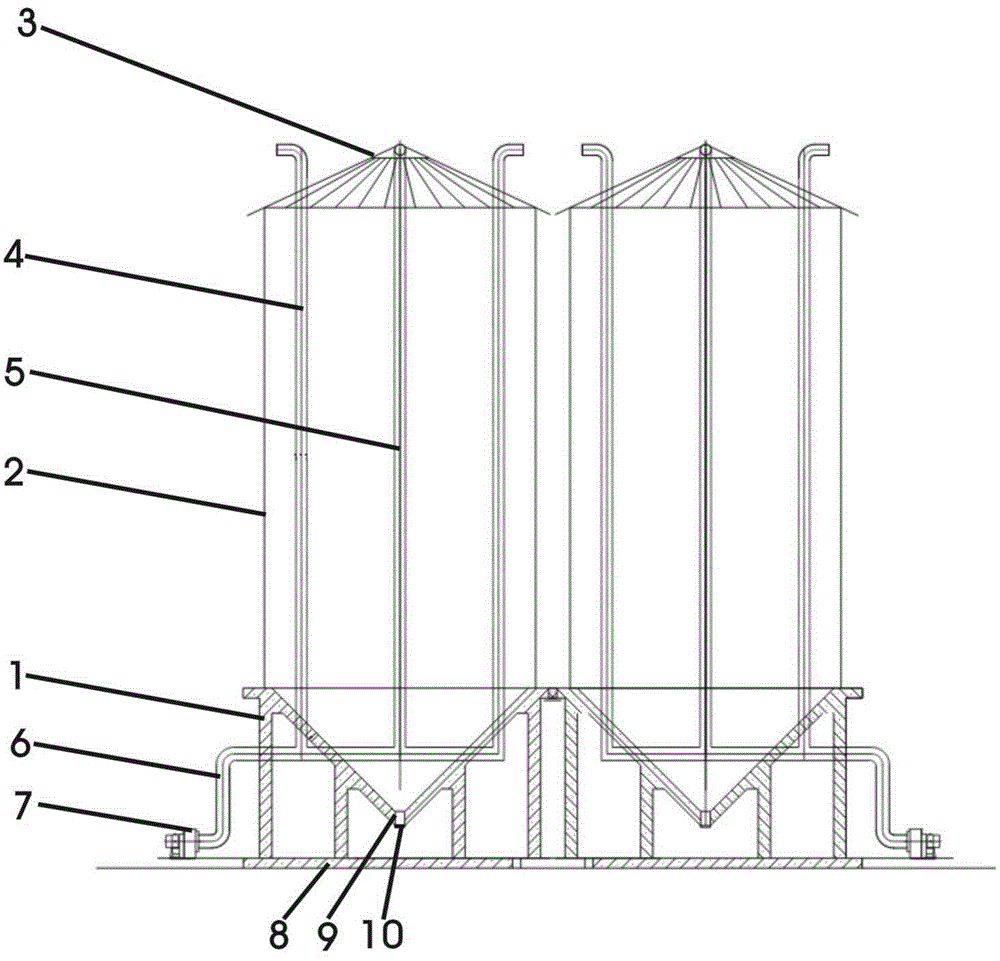

[0012] The present invention will be further described below in conjunction with accompanying drawing of description:

[0013] as attached figure 1 As shown, the present invention discloses a steel silo ventilation net system, including a concrete base (1), a steel silo body (2), a silo cover (3), interspersed ventilation ducts (4), an inner ventilation duct (5 ), external ventilation duct (6), fan (7), conveyor (8), characterized in that: the steel silo body (2) is set on the concrete base (1), interspersed with the ventilation duct (4) Interspersed between the steel silo body (2) and the silo cover (3), the inner ventilation duct (5) is set inside the steel silo body (2), and the fan (7) is connected by the outer ventilation duct (6) and the interspersed ventilation duct (4) Bottom connection, the conveyor (8) is located at the bottom of the steel silo body (2).

[0014] The bottom of the steel silo body (2) is provided with a conical funnel discharge port (9), and a disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com