Rolling machine for making hand-made dried noodles

A dried noodle and manual technology, which is applied in the directions of dough sheeting machine/rolling machine/rolling pin, dough processing, baking, etc. It can solve the problems of time-consuming, manpower and material resources, and laboriousness in the rolling process, and achieves wide applicability. , Save production costs, save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to solve the time-consuming and labor-intensive problems caused by the existing manual noodle rubbing, the invention provides a manual vermicelli rubbing machine.

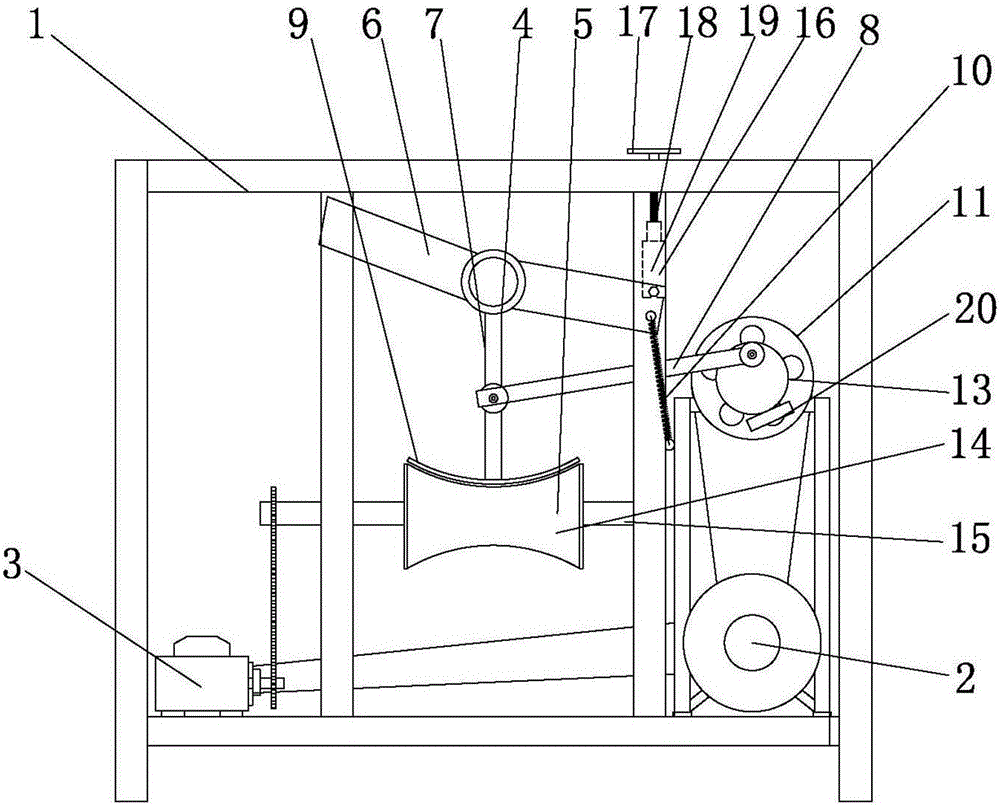

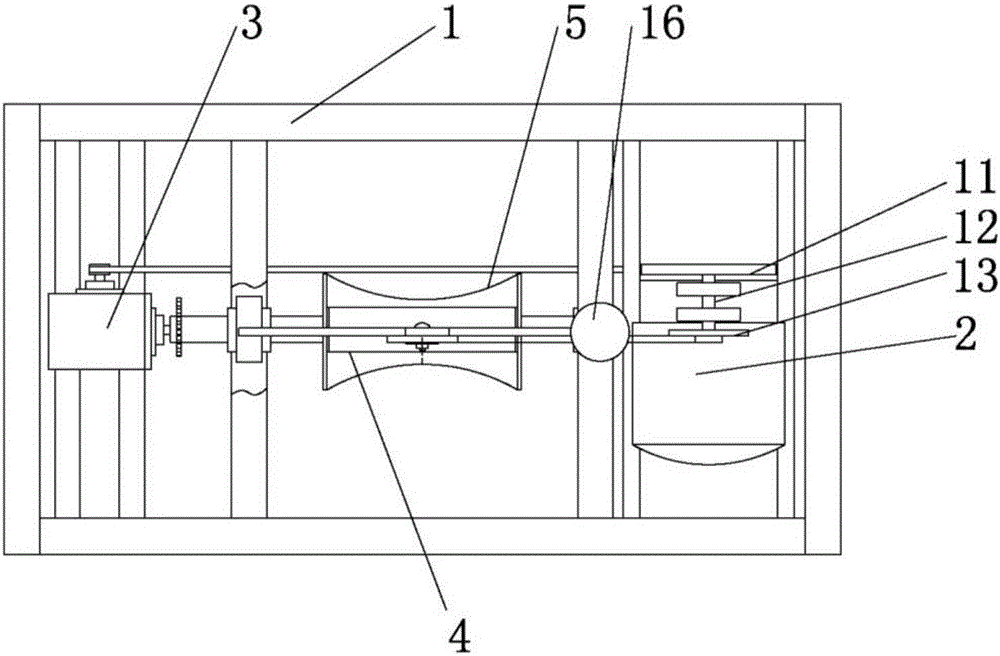

[0024] Such as figure 1 , figure 2 As shown, a kind of manual noodle rubbing machine includes a fixed bracket 1, a motor 2 installed at the bottom of the fixed bracket 1, a reducer 3, a swing noodle pressing device 4 at the top of the fixed bracket 1, and a rotating device installed at the middle of the fixed bracket 1. Roller assembly 5;

[0025] The swing pressing device 4 includes a crank arm 6, a straight arm 7, a connecting rod 8, a pressing plate 9, a spring 10, a large pulley 11, a connecting shaft 12 and an eccentric disc 13;

[0026] One end of the curved arm 6 is suspended in the air, and the other end is connected to the fixed bracket 1 by a spring 10; one end of the straight arm is connected to the middle part of the curved arm 6, and the other end is installed with a pressing plate 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com