Coal grinding device for efficient hot water boiler

A hot water boiler and coal grinding technology, applied in grain processing, etc., can solve the problems of low coal grinding efficiency, poor coal grinding fineness, and large equipment volume, and achieve high coal grinding efficiency, low power consumption, and equipment volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

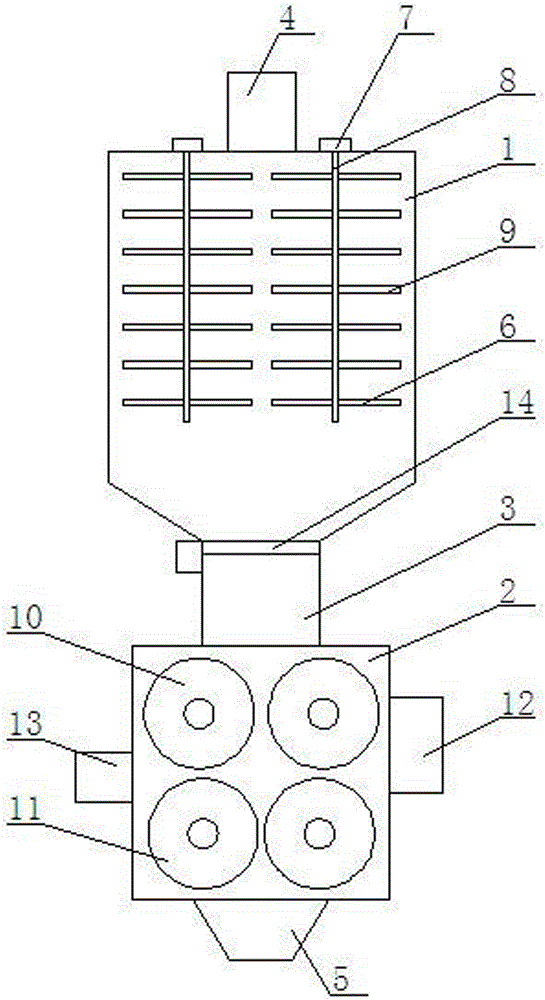

[0015] A coal grinding device for a high-efficiency hot water boiler, comprising a preliminary coal crushing box 1, a fine coal grinding box 2, a coal delivery pipe 3, a coal inlet pipe 4, and a coal discharge hopper 5, the bottom of the preliminary coal crushing box 1 The coal delivery pipe 3 is installed on the top of the fine grinding coal box 2; the top of the preliminary crushing coal box 1 is equipped with a coal inlet pipe 4; the bottom of the fine grinding coal box 2 is equipped with a coal outlet 5; the preliminary crushing coal box 1 There are two rotating striking devices 6 on the left and right of the internal device. The rotating striking device 6 is composed of a rotating motor 7, a rotating shaft 8, and a plurality of striking rollers 9. The rotating shaft 8 inside the crushing coal box 1, the plurality of striking rollers 9 are installed on the left and right sides of the rotating shaft 8; the upper and lower rows of roller pulverization devices 10 are install...

Embodiment 2

[0017] An electric control valve 14 is installed inside the coal delivery pipe 3 , and the electric control valve 14 is connected to a controller 13 .

Embodiment 3

[0019] The inner wall of the primary crushed coal box 1 is a thickened stainless steel inner wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com