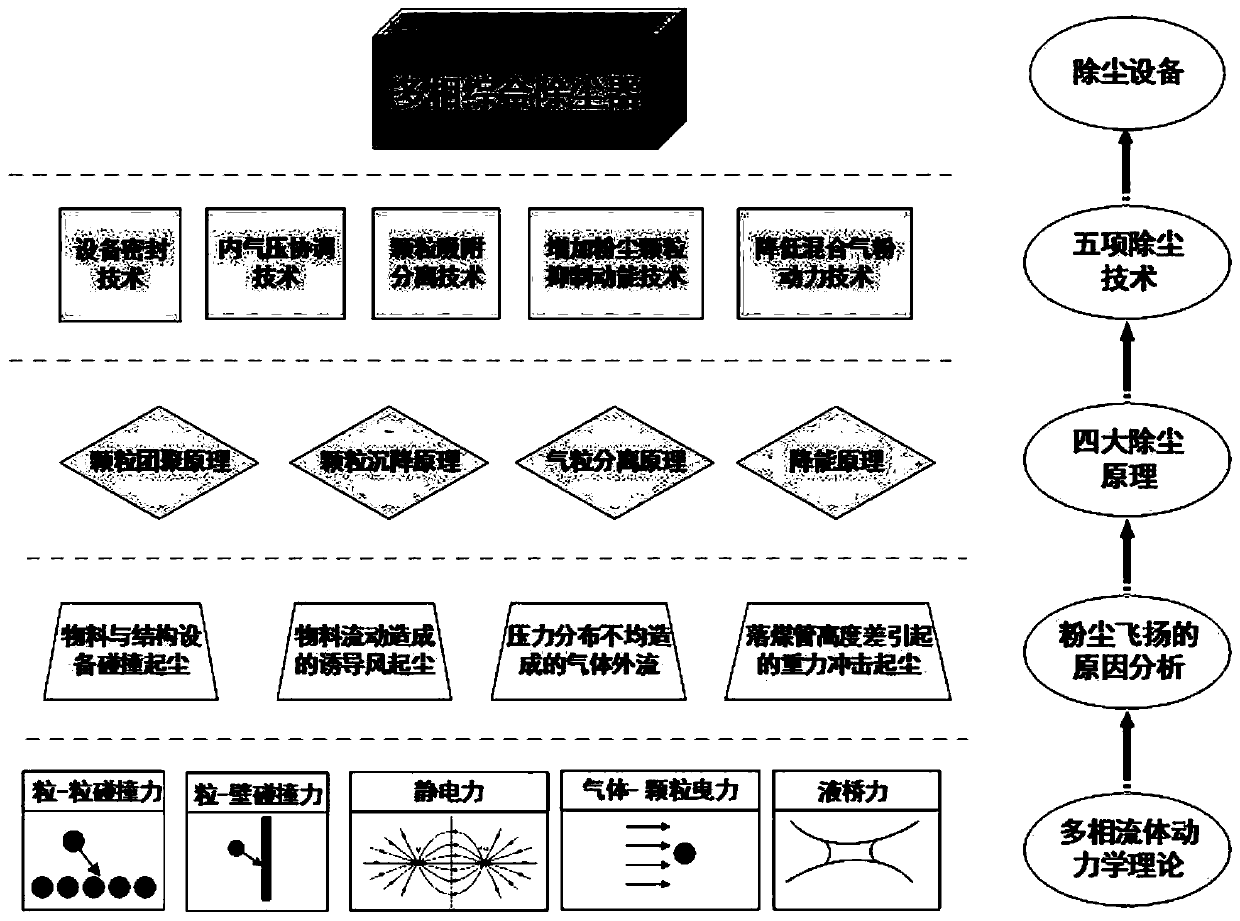

Multiphase integrated dust removal technology

A technology and dust technology, applied in the field of industrial dust removal, can solve the problems of complex dust removal, uneven air pressure distribution and high cost, and achieve the effect of strict theoretical basis, reasonable dust removal technology and simple equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] like figure 1 As shown, the present embodiment provides a multi-phase comprehensive dust removal technology, and the specific implementation is as follows:

[0040] Step 1. Analysis of the spatial distribution of the blanking port and belt conveyor equipment in the plant

[0041] For the transshipment and conveying process of materials in the factory after different processes, first analyze the relative position of the blanking port and the belt conveyor to obtain accurate elevation difference data, and obtain the speed of the material impacting the belt conveyor according to the law of potential energy and kinetic energy conversion. In this way, the weight of the material impact dust caused by the spatial distribution is obtained; at the same time, due to the height difference between the discharge port and the belt conveyor, the impact velocity of the material is caused, and the degree of airflow entrainment is also analyzed, so as to analyze the indirect cause of mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com