A battery coating sealing agent nozzle

A technology of sealing agent and nozzle, which is applied in spray booths, spray devices, liquid spray devices, etc., can solve the problems of affecting the operating environment, waste of resources, high cost, etc., and achieve the effect of improving spray quality, avoiding flowing around, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

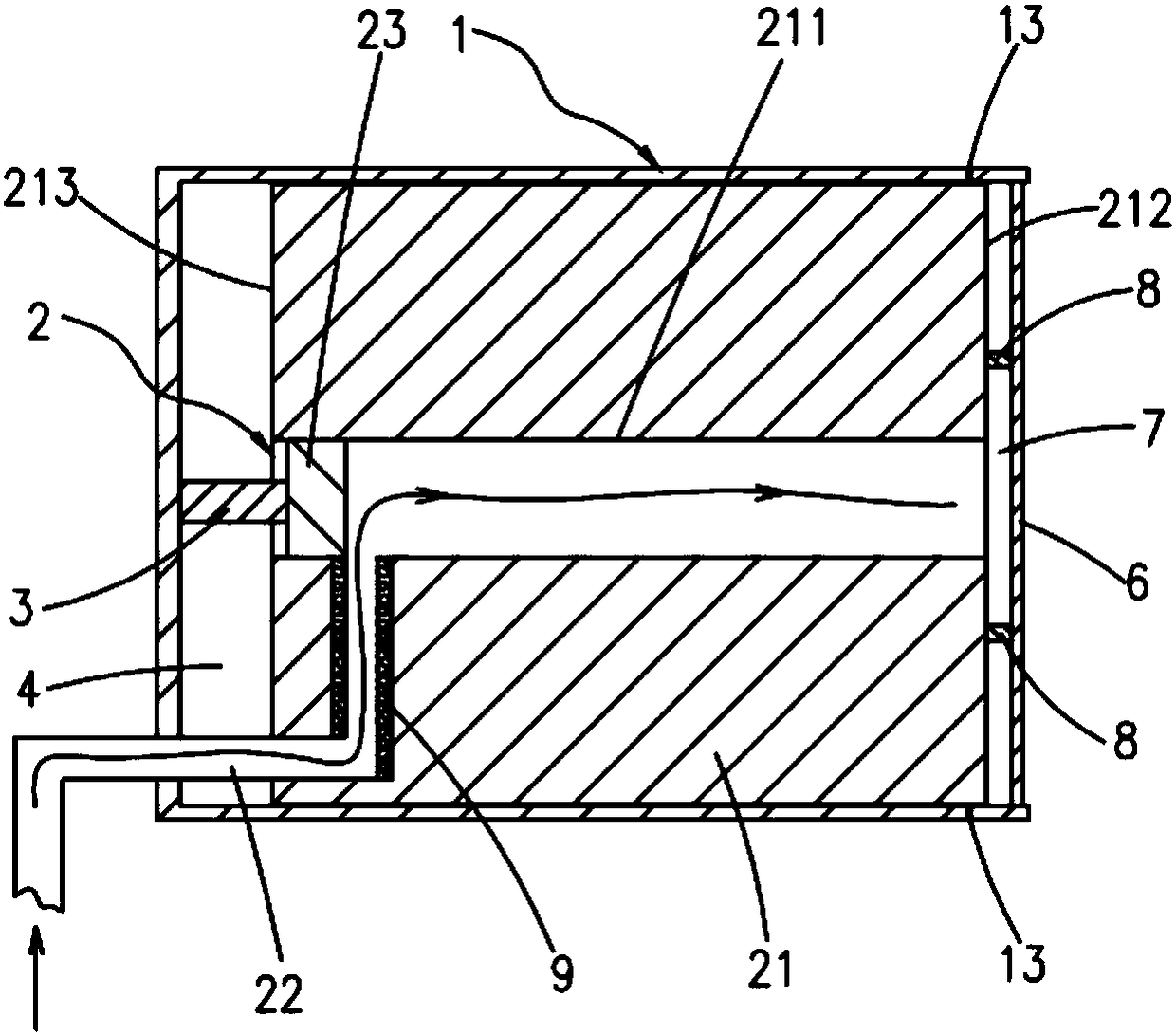

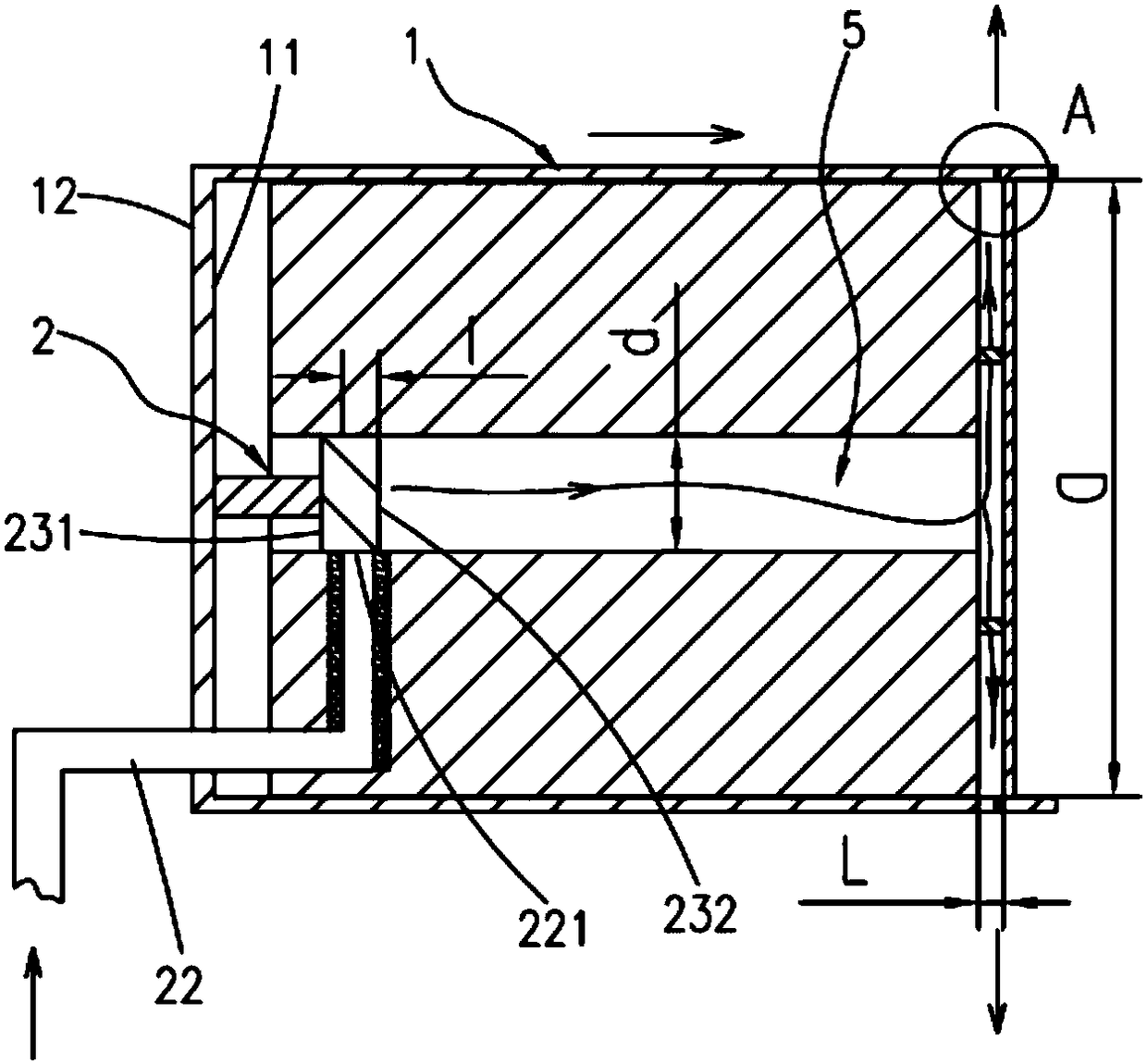

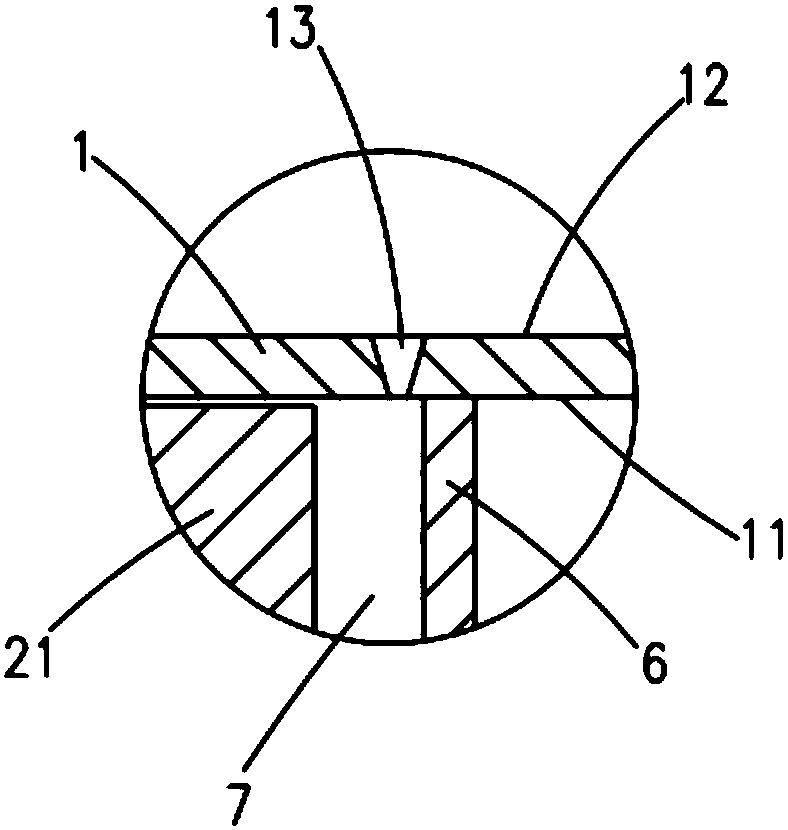

[0033] Such as figure 1 and figure 2 As shown, the present invention provides a battery sealant spray head, including a spray cover 1 whose outer diameter is adapted to the inner diameter of the battery steel case to be coated and a push sealant mechanism 2 placed in the cavity of the spray cover 1, The pushing sealing agent mechanism 2 includes a agent cylinder 21, an agent tube 22 and a piston 23, and the inside of the agent cylinder 21 is provided with a through hole for containing the sealing agent adapted to the external dimensions of the piston 23 along its axial direction. 211, the piston 23 is airtightly arranged in the through hole 211 and is fixedly connected with the spray cover 1 through the connecting rod 3, and an air container communicating with the outside atmosphere is formed between the outer end 231 of the piston 23 and the inner wall 11 of the spray cover 1 Cavity 4, a capacity-adjustable storage chamber 5 is formed between its inner side end 232 and the ...

Embodiment 2

[0043] Such as Figure 7 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. This embodiment two and figure 1 The difference of the first embodiment shown is that: the air chamber 4 is symmetrically provided with a spring 10, one end of the spring 10 is fixedly connected to the inner wall 11 of the spray cover 1, and the other end is connected to the rear end of the agent tank 21. The parts 213 are against each other, and a spring 10 is added in the air chamber 4. On the one hand, the stability of each push stroke of the piston 23 is improved to ensure that the spraying port 13 sprays the sealing agent evenly and continuously, and the self-elasticity of the spring 10 is used to complete the sealing. After the spraying agent is applied, it is beneficial for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com