Cooling device for production of aluminum composite plate

The technology of an aluminum composite panel and a cooling device is applied in the field of cooling devices, which can solve the problems of uneven cooling and uneven air output of the aluminum composite panel, and achieve the effects of simple structure, uniform cooling and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

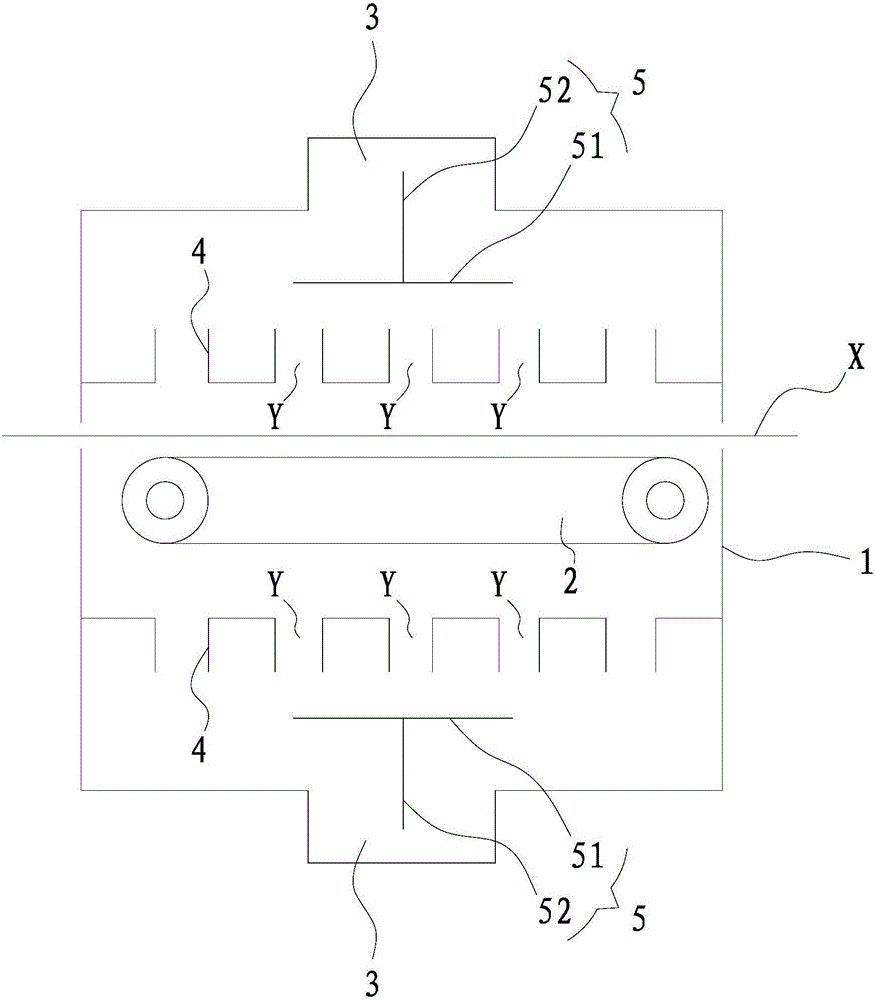

[0025] like figure 1 As shown, the cooling device for the production of aluminum composite panels provided in this embodiment includes a box body 1 with an inlet and an outlet; it is located in the box body 1 for driving the aluminum composite panel X to enter and exit from the inlet. The conveying unit 2 from the feed port; the air supply unit (not shown in the figure); and the air duct 3 used to connect the air supply unit with the box body 1; wherein the outlet of the air duct 3 is located at the top of the box body 1 for cooling The device also includes a plurality of partition plates 4 perpendicular to the moving direction of the aluminum composite panel X and located above the conveying unit 2. The plurality of partition plates 4 are spaced apart and arranged side by side. When the cooling device is working, the wind blows After entering the box body 1 from the air channel 3 , it blows to the surface of the aluminum composite panel X from the gap Y between every two adja...

Embodiment 2

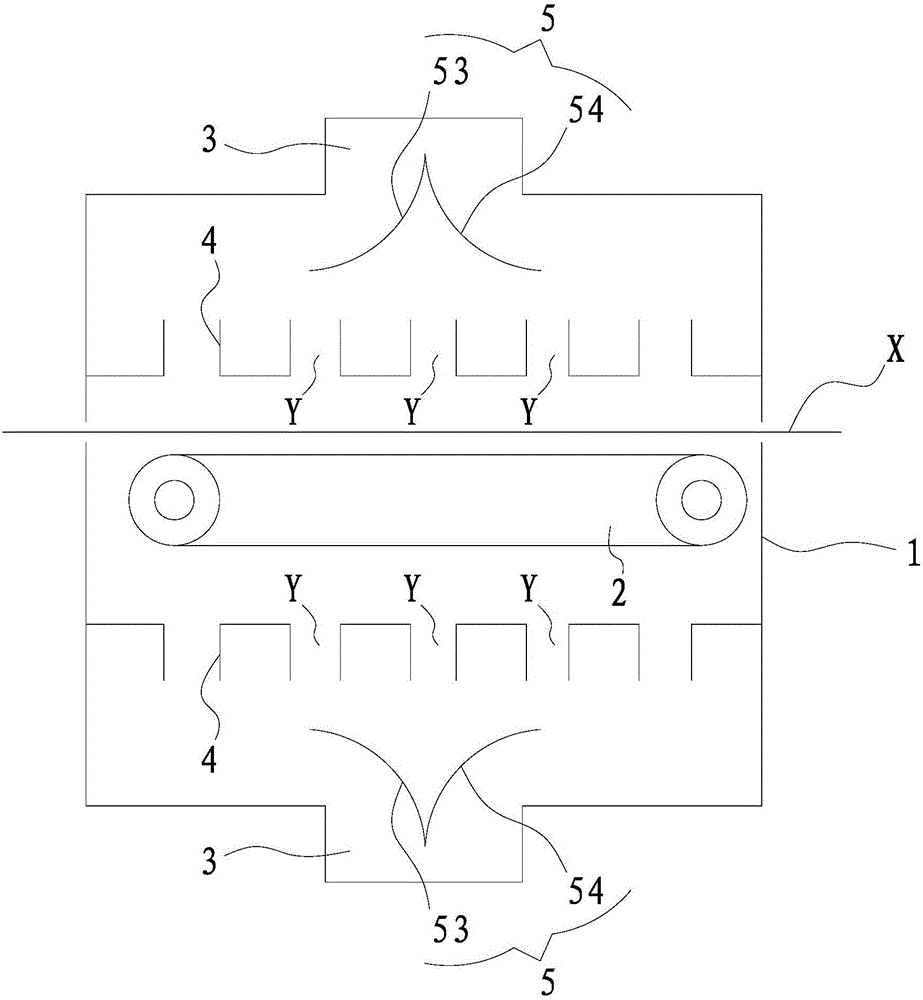

[0036] like figure 2 As shown, the structure of the cooling device involved in this embodiment is basically the same as that of Embodiment 1. The difference is that the flow distribution assembly 5 in this example includes a set of outlets in the middle of the air duct 3 from top to bottom, and to both sides. The curved first arc-shaped plate 53 and the second arc-shaped plate 54, the upper ends of the first arc-shaped plate 53 and the second arc-shaped plate 54 are fixed and integrated, and separate the two adjacent pieces directly below the outlet of the air duct 3 The gap Y between the plates 4 is shaded.

[0037] Specifically, the first arc-shaped plate 53 and the second arc-shaped plate 54 are arranged symmetrically. The split is relatively even.

[0038] To sum up, after the cooling device used in this application, the wind first spreads to the periphery of the box through the splitter assembly, and then through the evenly distributed gaps, the front and back sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com