Automatic demolding device for copper product continuous-extrusion tailings

A technology of automatic demolding and tailing, applied in the field of copper and copper alloy products processing machinery, can solve the problems of increasing the risk of mold damage, cumbersome processing process, long processing cycle, etc., to avoid the risk and probability of damage, simple design structure, Effects that increase effectiveness and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

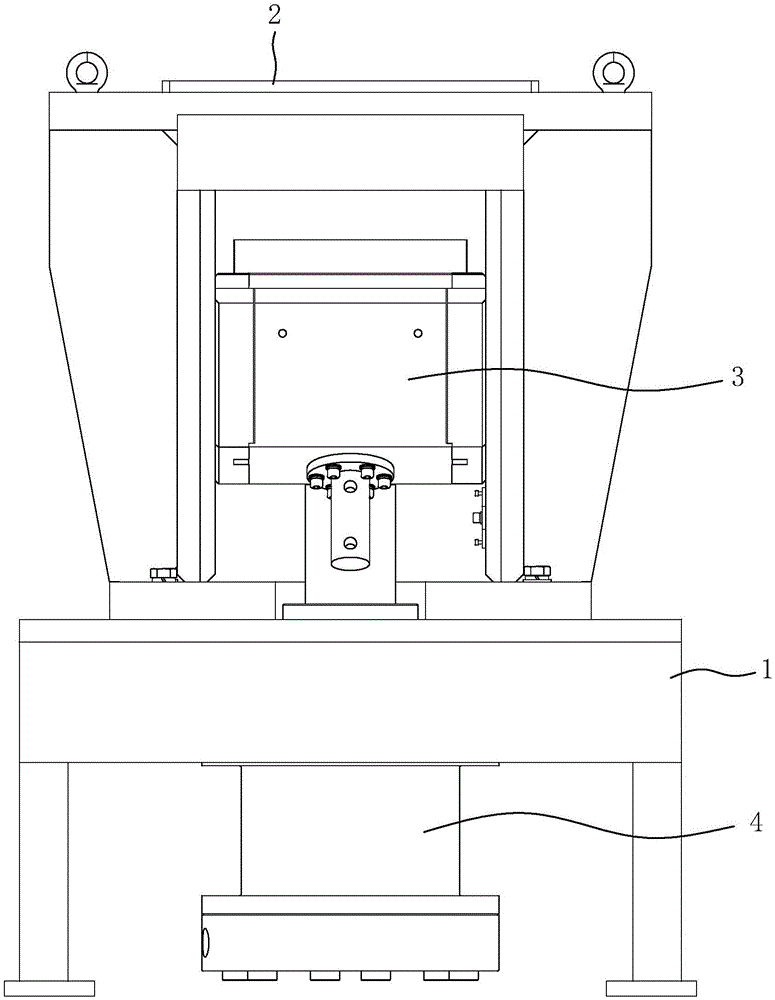

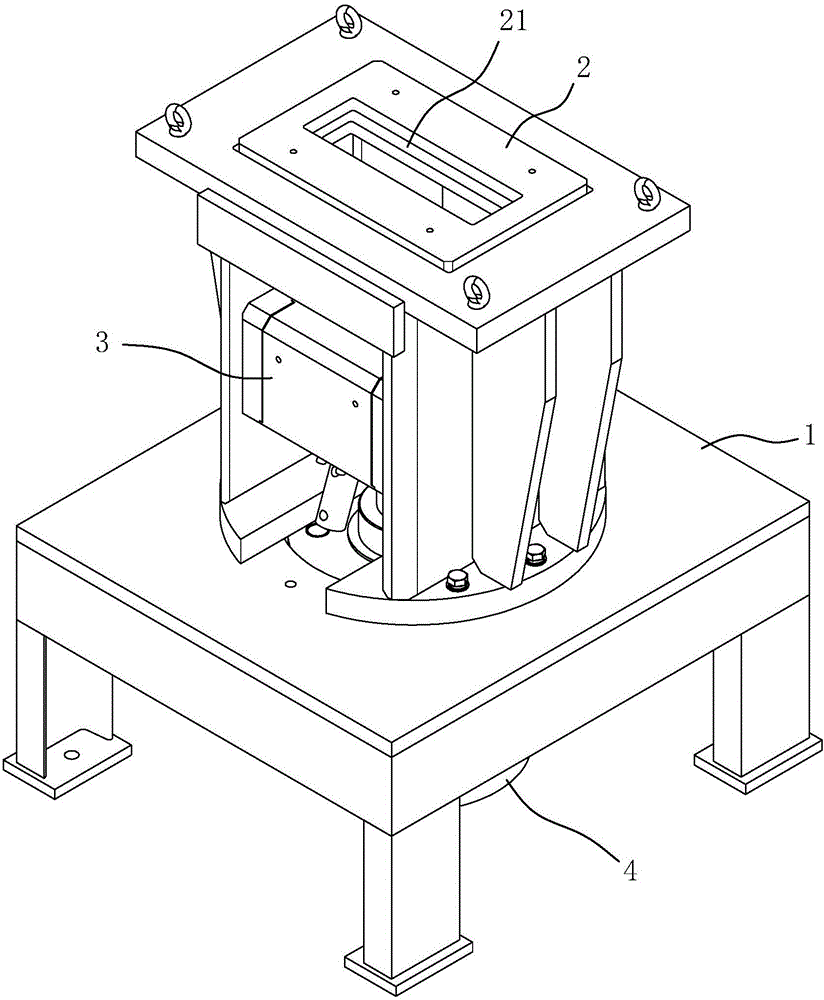

[0009] Such as Figure 1-2 As shown, an automatic stripping device for continuous extrusion tailings of copper products includes a mold base 2 fixed on the frame 1 for inserting tailings, a mold base 2 for clamping tailings and The frame 1 is slidably connected up and down the clamping mechanism 3 , and the driving mechanism 4 installed on the frame 1 is used to drive the clamping mechanism 3 to move. After completing the continuous extrusion of the copper product, cut off the tailings, remove the extrusion die, place it on the mold base 2, and insert the tailings into the through hole 21 of the mold base 2, the mold is then stuck on the mold base 2, and then The tail material is clamped by the clamping mechanism 3, and then the driving mechanism 4 drives the clamping mechanism to move down, and the tail material is completely pulled out from the extrusion die, thereby realizing the separation of the extrusion die and the tail material. During this process, neither the tail m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com