Production device for cement pipes

A technology for production devices and cement pipes, which is applied to ceramic molding machines, molds, manufacturing tools, etc., can solve the problems of increasing the difficulty of product production and subsequent maintenance, prolonging the production cycle of products, increasing the space occupied by equipment, etc., to increase production efficiency. and quality, reducing the difficulty of post-maintenance, and reducing the overall space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The patent of this case will be further described below in conjunction with the accompanying drawings. Obviously, this specific embodiment is only a further description of the present invention, and should not be construed as limiting the technical solution of the patent of this case. On the basis of the structure or principle provided by the present invention Various modifications can be extended, and these modified technical solutions are all within the protection scope of the present invention.

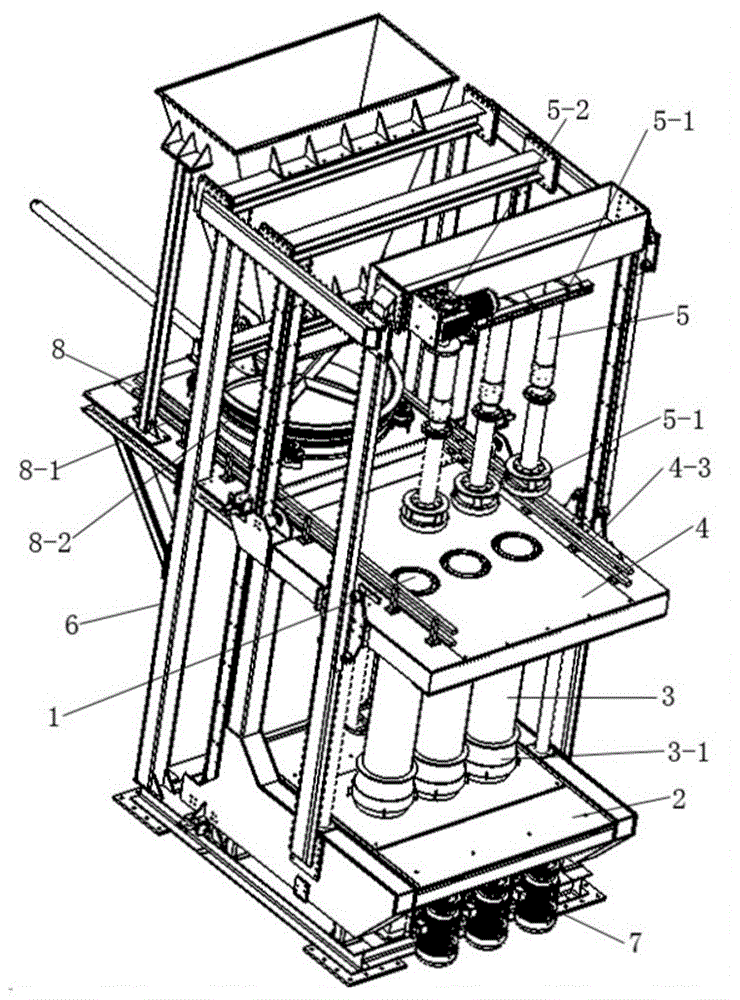

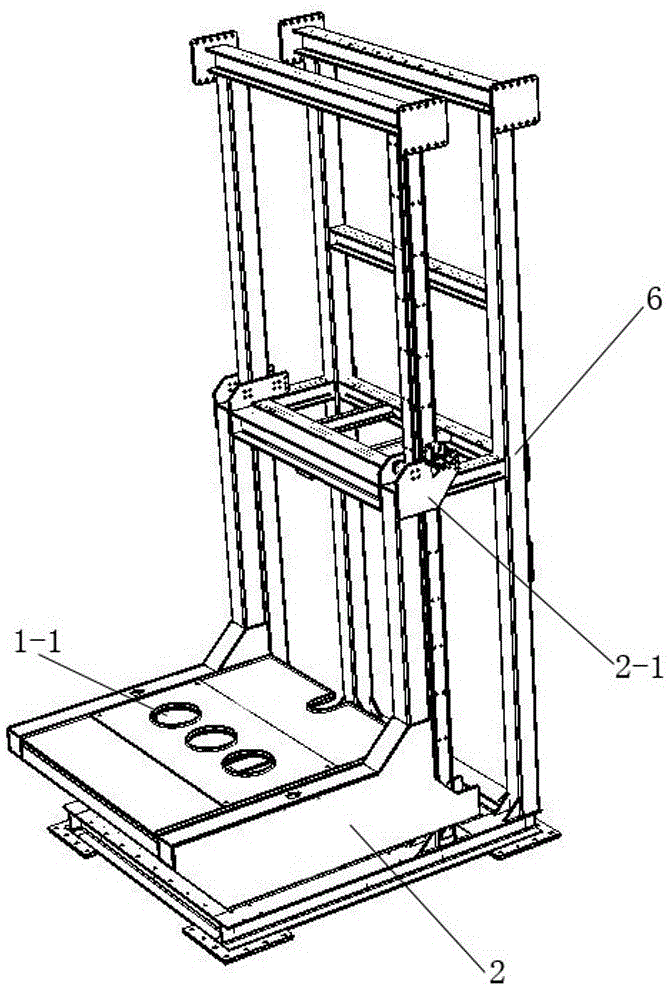

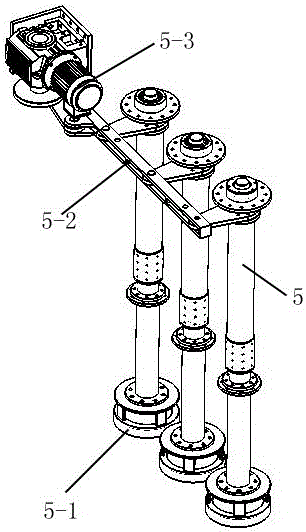

[0030] Such as Figure 1-5 Shown, a kind of cement pipe production device comprises:

[0031] Mandrel 1; the shape of the mandrel 1 is determined according to the shape of the prepared cement pipe. If a circular cement pipe is prepared, the mandrel 1 is cylindrical. If a square cement pipe is prepared, the mandrel 1 is square.

[0032] Cement pipe lifting platform 2, the cement pipe lifting platform 2 is provided with a mandrel through hole 1-1, the mandrel through hole 1-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com