Style-changed vehicle model vehicle body structure design method based on trunk door model change

A technology for trunk door and structure design, applied in the field of body structure design, can solve the problems of difficulty in shortening the product development cycle, large amount of design changes, optimization, etc., so as to shorten the design time and trial production cycle, save the manufacturing cost, and expand the scope of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further illustrate the technical means and functions adopted by the present invention to achieve the intended invention purpose, the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0027] At present, in addition to launching new models on the market, most automakers will also introduce redesigns for existing models. The embodiment of the present invention provides a body structure design method of a remodeled model, which mainly aims at changing the shape of the trunk door at the rear of the car. Product development cycle, reduce vehicle development costs, and minimize duplication of labor in the design and manufacture of body structures.

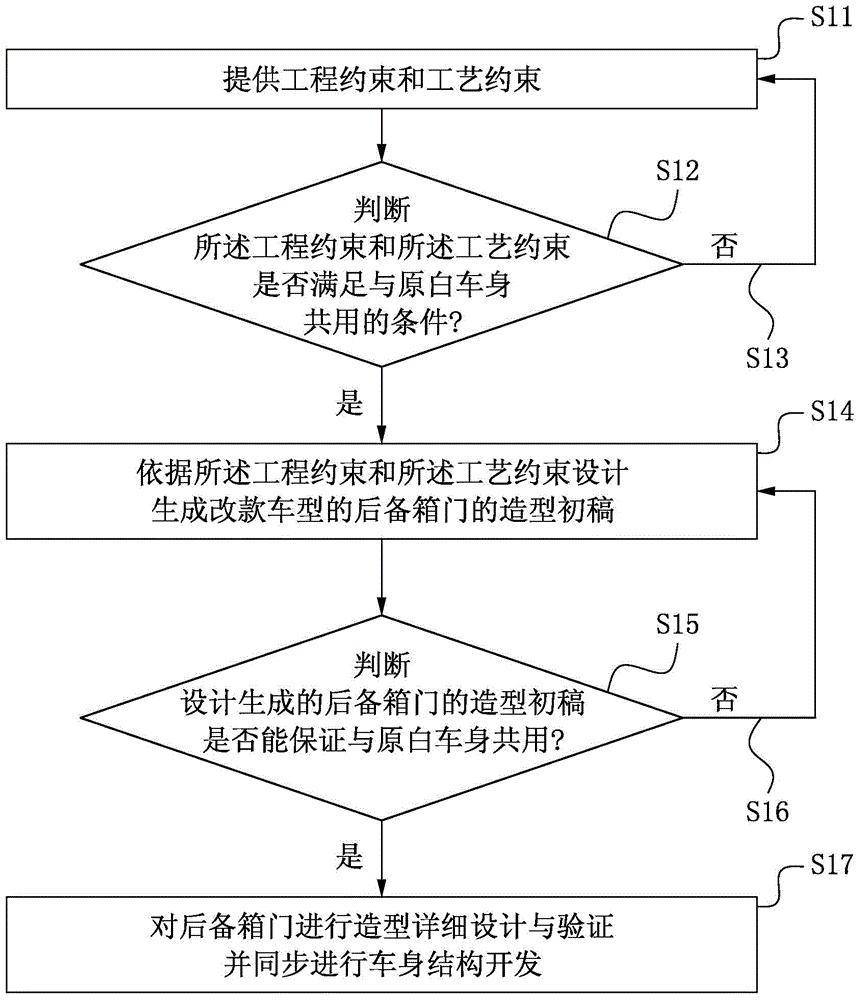

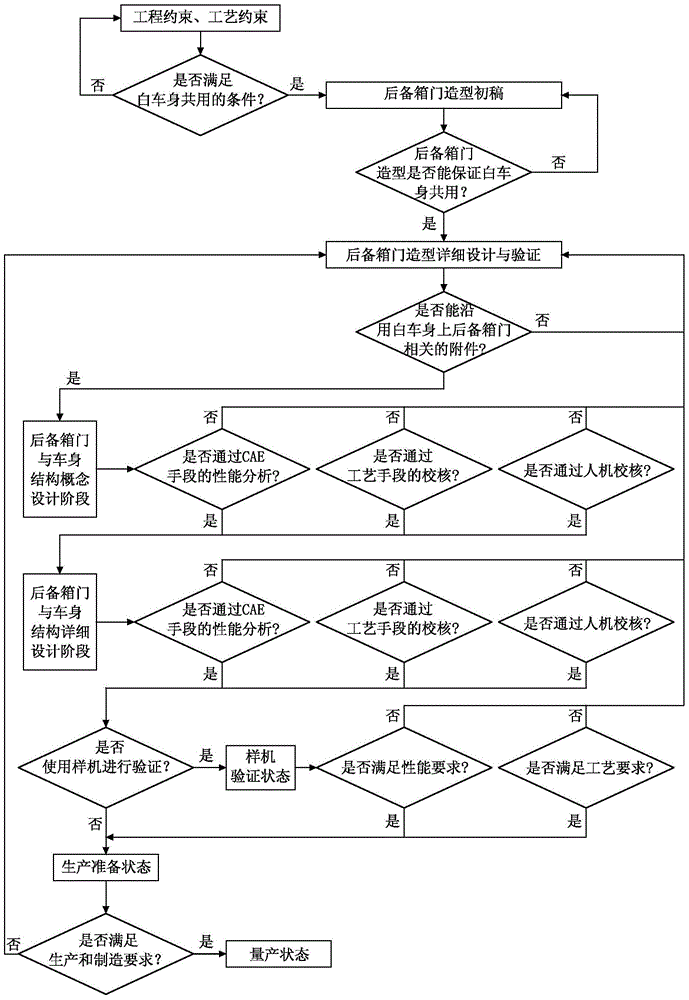

[0028] figure 1 It is a flow chart of the body structure design method for a modified vehicle model in the embodiment of the present invention, figure 2 It is a logic diagram of the body structure design method of the modified vehicle model ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com