Conducting yarn, manufacture equipment, fabric woven by conducting yarns

A kind of conductive yarn and equipment technology, applied in the direction of yarn, fabric, textile, etc., can solve the problems of moisture loss, machine running noise, cost a lot of electricity, time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the technical means of the present invention and the effects it can achieve more completely and clearly disclosed, the detailed description is as follows. Please refer to the disclosed drawings and drawing numbers:

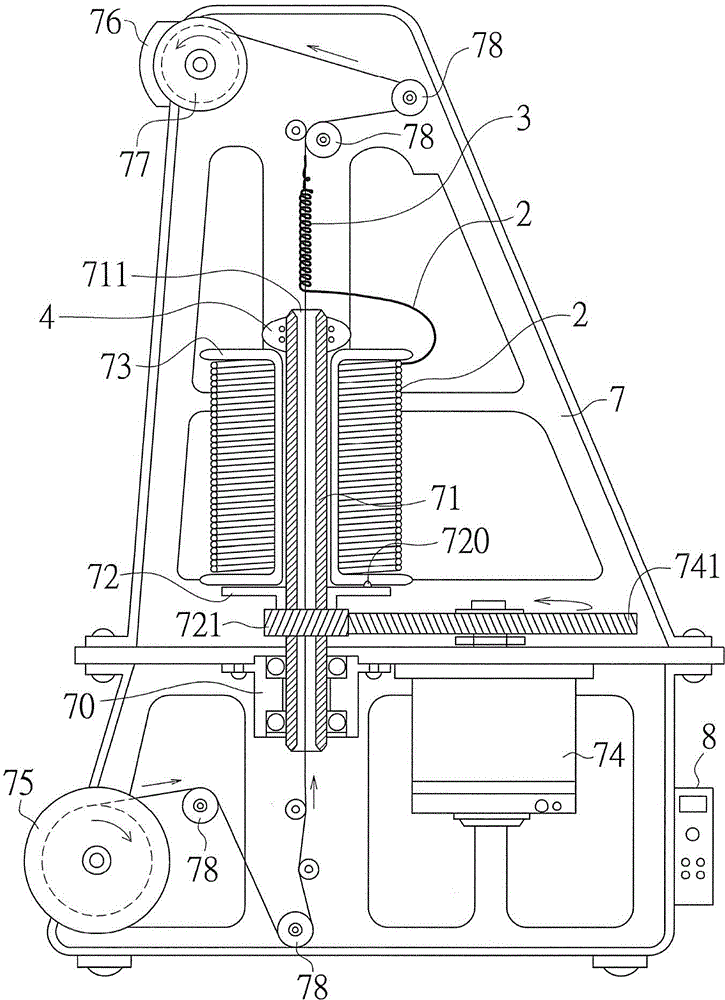

[0046] First, see Figure 2 ~ Figure 4 Shown is a schematic diagram of a conductive yarn and its manufacturing equipment of the present invention, and its conductive yarn mainly includes:

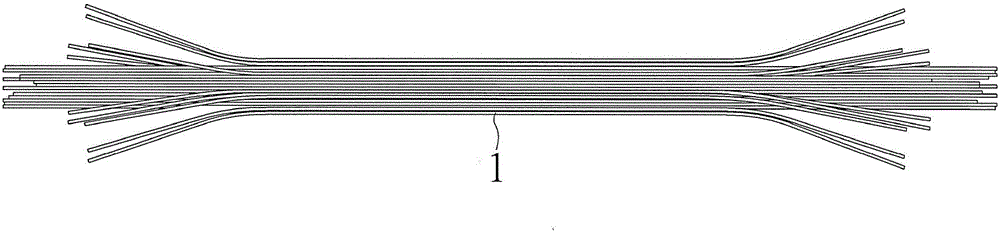

[0047] an insulating main axis 1 consisting of multi-core filaments; and

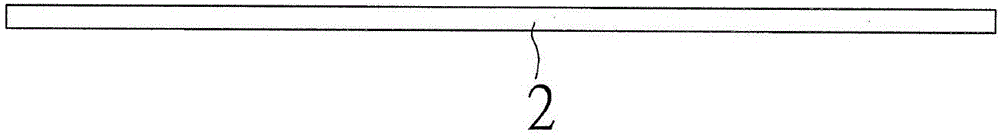

[0048] A fine metal wire 2 wound on the outside of the main axis 1, using conductive metal filaments (for example: gold, silver, copper, tungsten and molybdenum, etc. fine wires), and the diameter is between 0.02 ~ 0.12mm is the best , that is, the fine metal wire 2 is a metal filament with a diameter of 0.02-0.12 mm and made of a conductive metal, wherein,

[0049] Guided by a device, the fine metal wire 2 is spirally wound outside the main axis 1 to form a stretchable and elas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com