Construction device and construction method using sea sand as concrete fine aggregate

A technology of fine aggregate and concrete, which is applied in building thermal insulation materials, formwork/formwork/work frame, on-site preparation of building components, etc. Guaranteed not to be corroded, thoroughly dechlorinated, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the drawings and specific embodiments.

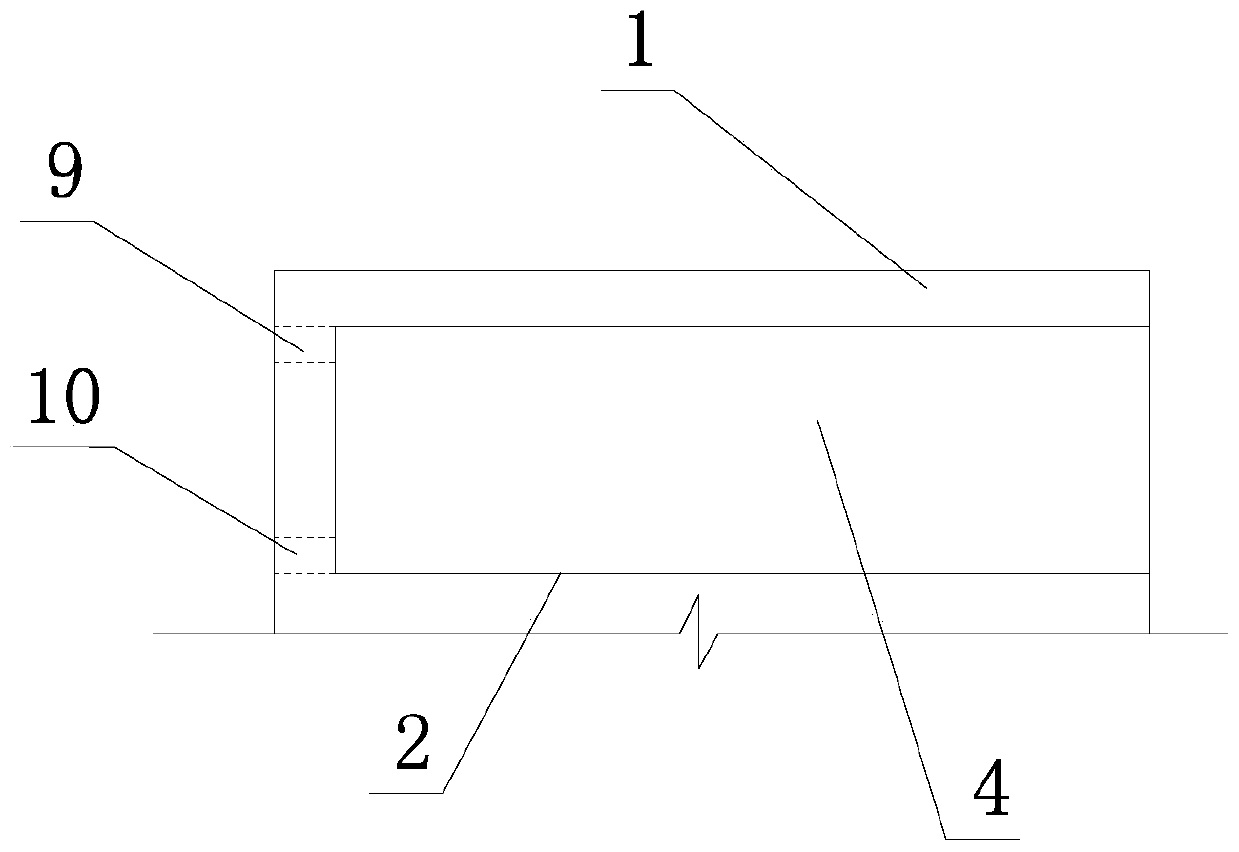

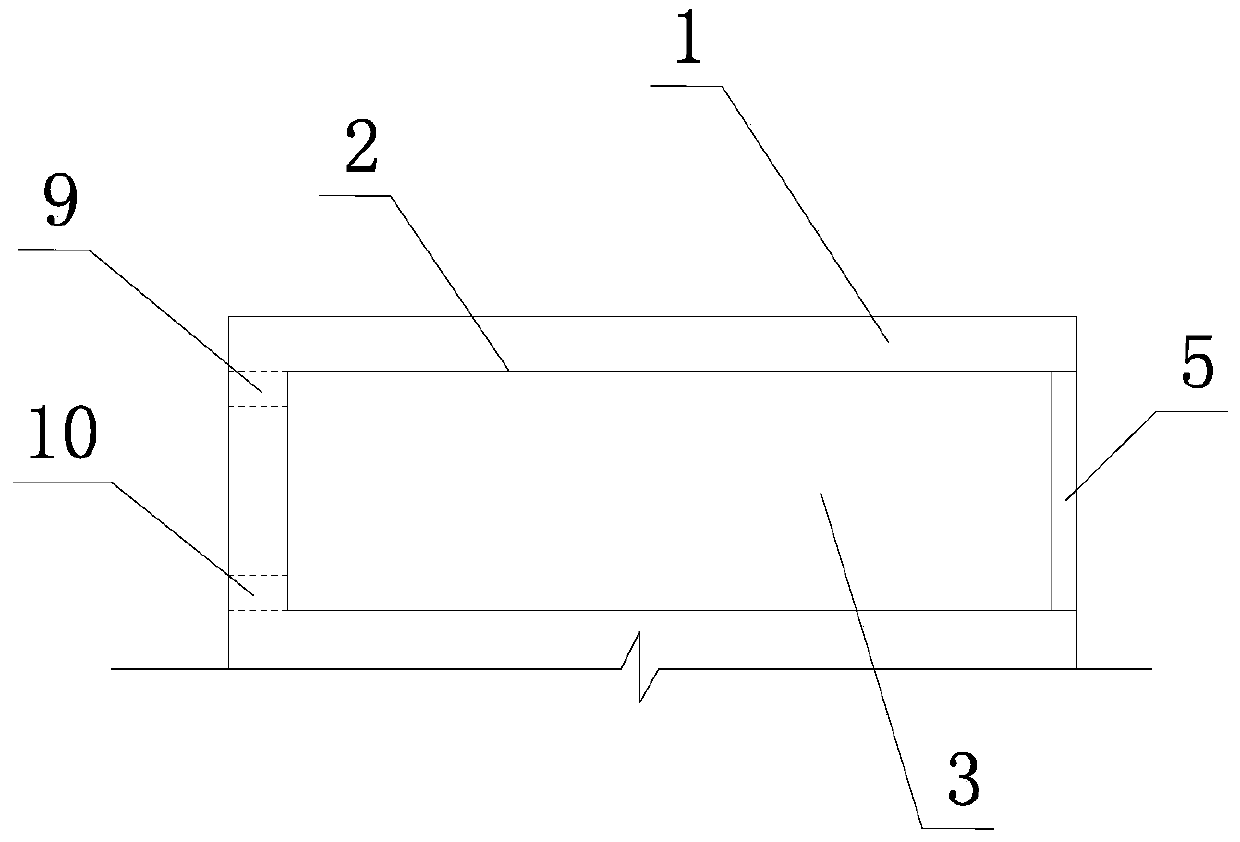

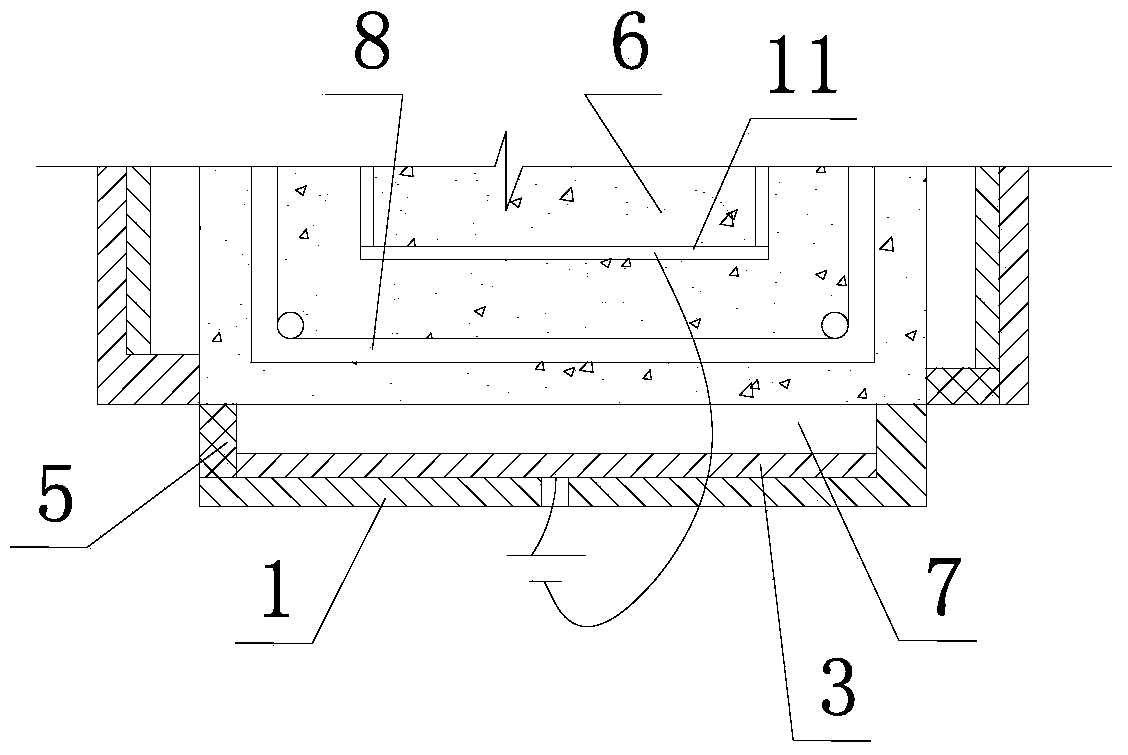

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention uses sea sand as a device for concrete fine aggregate construction, which includes a DC power supply and a formwork 1 for pouring concrete. The inner surface of the template 1 is provided with a sliding groove 2, the bottom of the sliding groove 2 is fixed with a stainless steel plate 3, and the sliding groove 2 is slidably fitted with a drawing plate 4 having the same length as the sliding groove 2. When the drawing plate 4 is fitted in the chute 3, the drawing plate 4, the stainless steel plate 3 and the bottom of the chute 2 abut in sequence. The opening of the chute 2 is located on one side of the template 1, that is to say, one end of the chute 2 is open and one end is closed. The open end of the chute 2 extends to one side of the template 1, so as to ensure that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com