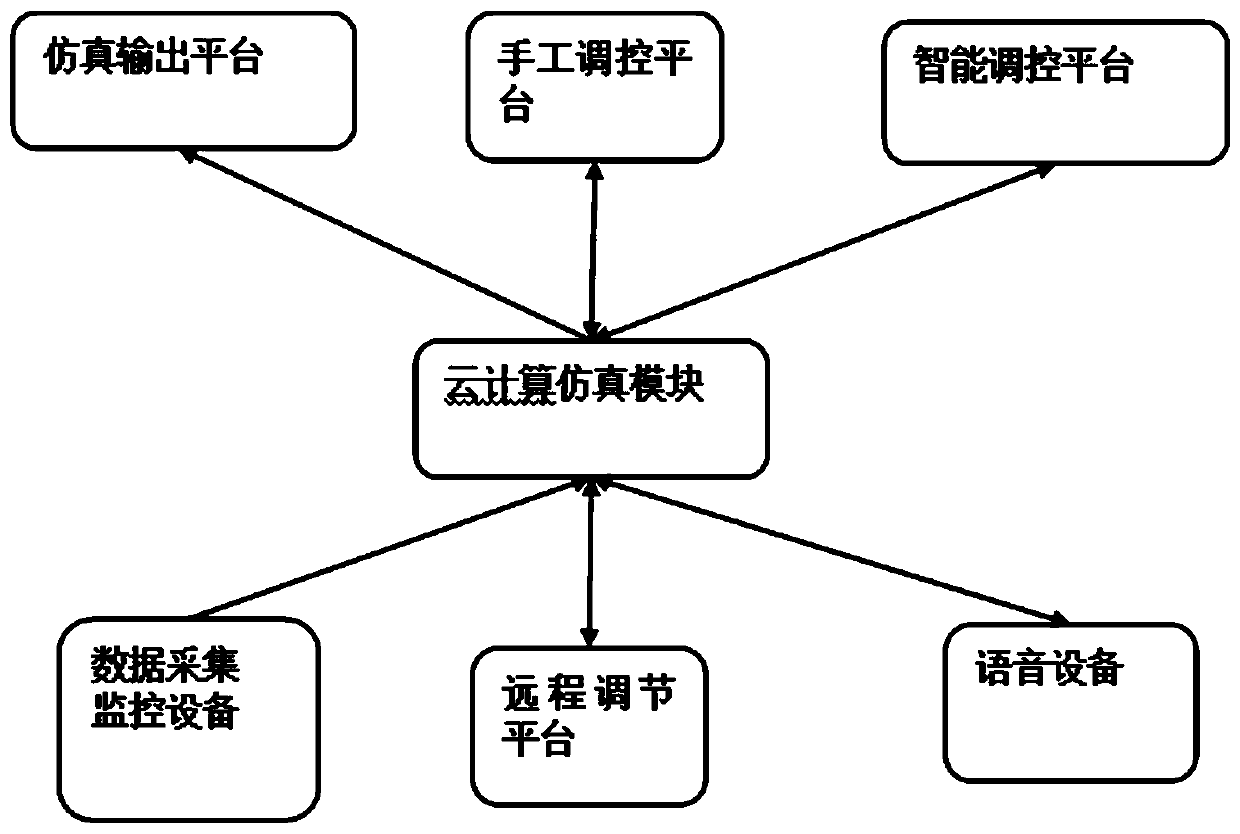

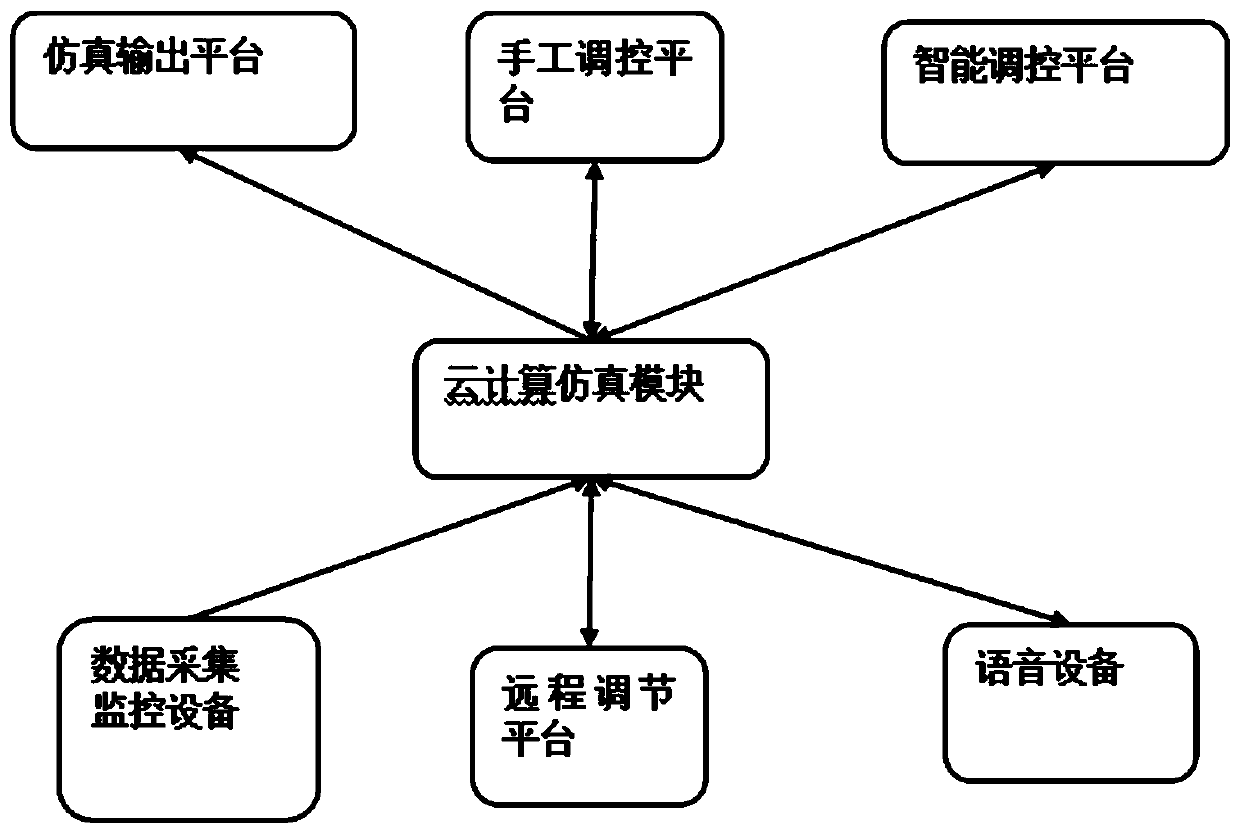

Cloud module-based remote-control intelligent electro osmosis seepage prevention and moisture prevention system

A remote control and intelligent technology, applied in the field of remote control intelligent electro-osmosis anti-seepage and moisture-proof systems, can solve the problems of decreased combined water content, decreased concrete strength, carbonization, etc., to prevent excessive electro-osmosis, realize real-time performance, and facilitate operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In Example 1, the repair of this example is exemplified by a defect in the form of an interfacial crack at the joint between the concrete and the base.

[0029] Using ordinary cement as the binder, the fine material is river sand (density 2.61, water absorption 1.72%, fineness modulus 2.7), the coarse material is crushed sandstone (density 2.62, water absorption 0.67%, fineness modulus 6.67), For the main rod and stirrups, the diameters of the steel bars are 12mm and 5mm, respectively. The chemical composition of steel bars is listed in Table 1;

[0030] C Si mn P S Fe 0.12 0.11 0.42 0.02 0.02 99.3

[0031] Table 1 Chemical composition percentage of steel bars

[0032] The proportion of concrete is shown in Table 2. The slump of the freshly mixed concrete is 11 ± 1 cm, and the air content is 3 ± 1%. The water-cement ratio is 0.6. In order to accelerate the corrosion process, add 9kg / m-3 solid NaCl during the concrete mixing process;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com