Plant area chilled water supplying and air conditioner cabinet condensate water recycling combined system

A combined system and chilled water technology, applied in the direction of preventing condensed water, refrigerators, refrigeration components, etc., can solve the problems of wasting condensed water and wasted cooling capacity of condensed water, and achieve the effects of saving energy, reducing the concentration of chloride ions, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

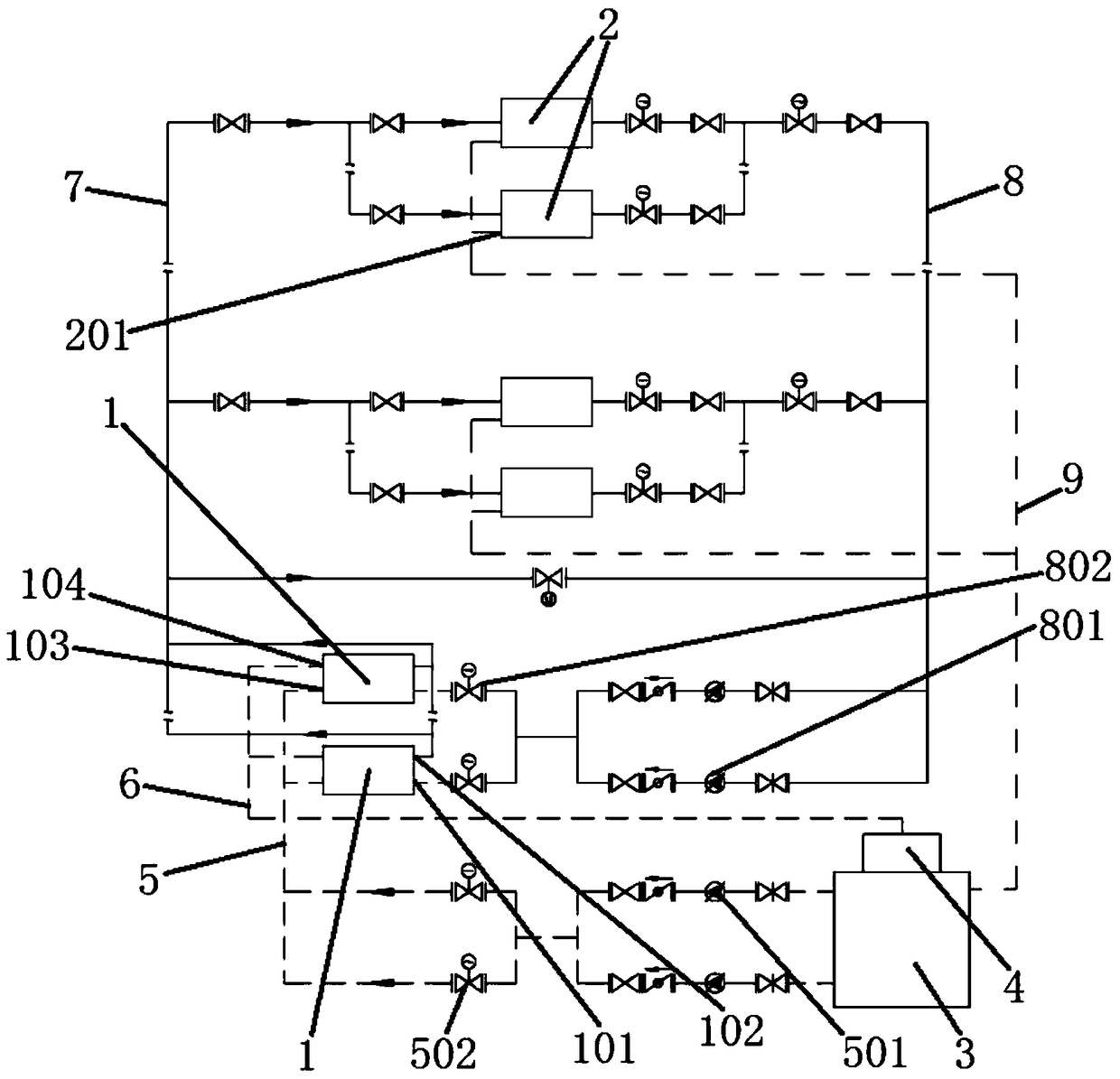

[0025] Such as figure 1 A combined chilled water supply and air-conditioning box condensate recovery system shown in the factory area includes a chiller 1, an air-conditioning box 2, a cooling pool 3, and a cooling tower 4. The chiller 1 is provided with a high-temperature chilled water inlet 101 and a low-temperature chilled water inlet 101. Outlet 102, low-temperature chilled water outlet 102 communicates with high-temperature chilled water inlet 101 through air-conditioning box 2, air-conditioning box 2 is provided with condensed water outlet 201, cooling water pool 3 is connected with condensed water outlet 201, and cooling water pool 3, refrigerator 1. The cooling towers 4 are sequentially connected in series.

[0026] Wherein, the refrigerator 1 is also provided with a low-temperature cooling water inlet 103 and a high-temperature cooling water outlet 104 , the low-temperature cooling water inlet 103 communicates with the cooling pool 3 , and the high-temperature cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com