A kind of production method of sodium iron edetate

A technology of ferric sodium edetate and tetrasodium edetate, which is applied in the field of biology and new medicine, and can solve the problems of difficult separation of by-products, difficulty in separation, and low purity of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

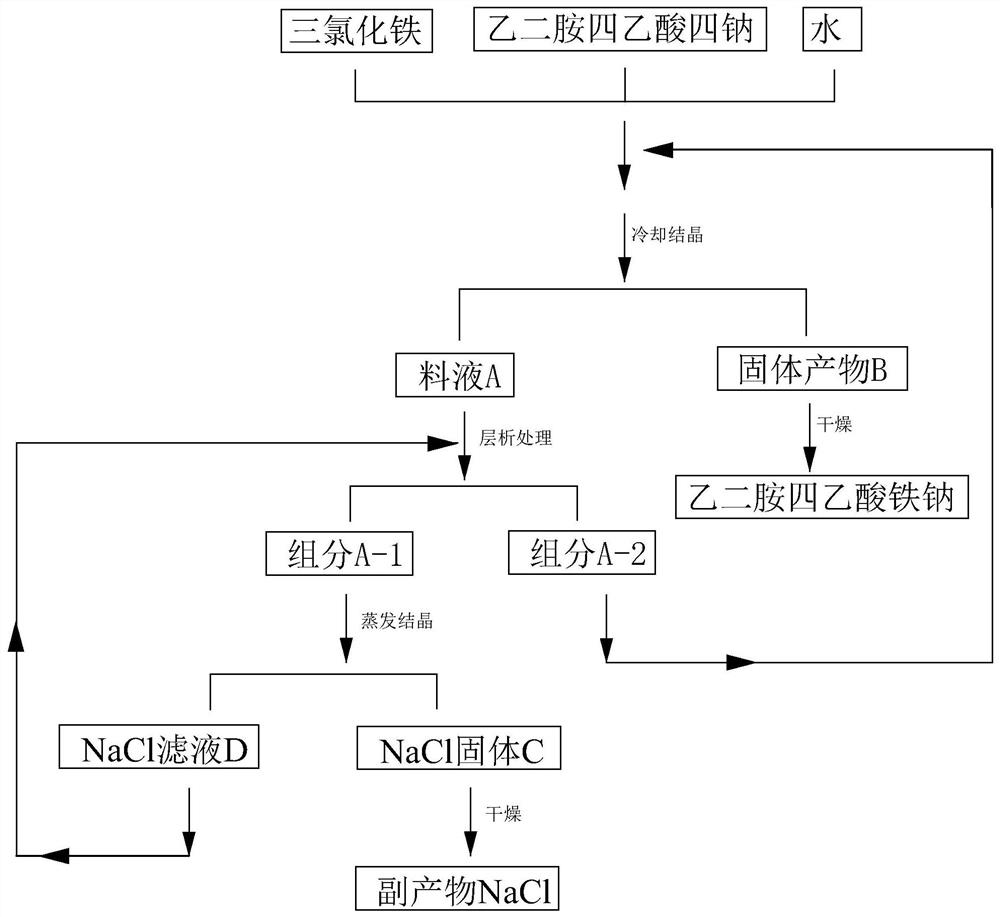

[0041] A kind of production method of ferric sodium edetate, such as figure 1 shown, including the following steps:

[0042] S1. Preliminary reaction: Add ferric chloride, tetrasodium ethylenediaminetetraacetic acid and water into the reactor at a molar ratio of 1:1:25, react for 1 hour, and the reaction is completed to obtain the raw material solution, and then the raw material solution is mixed at 10 Cooling and crystallization at a temperature of ℃ for 1.5h. The cooling and crystallization process can be realized in a cooling crystallizer. After the crystallization is completed, the first separation operation is performed to obtain feed liquid A and solid product B. In this step, the first separation operation can be a filtration operation, or It can be a centrifugal separation operation;

[0043]Specifically, when the first separation operation is a filtration operation, the raw material liquid after cooling and crystallization is filtered in a filter with a mesh size of ...

Embodiment 2

[0054] A kind of production method of ferric sodium ethylenediamine tetraacetate, carry out difference according to the method in embodiment 1 and be,

[0055] S1. Preliminary reaction: Add ferric chloride, tetrasodium ethylenediaminetetraacetic acid and water into the reactor at a molar ratio of 1:1.5:30, react for 100 minutes, and obtain the raw material liquid after the reaction is completed, and then put the raw material liquid at 18 Cool and crystallize at a temperature of 105min for 105min. The cooling crystallization process can be realized in a cooling crystallizer. After the crystallization is completed, the first separation operation is performed to obtain feed liquid A and solid product B. The first separation operation here can be a filtration operation or is a centrifugal separation operation;

[0056] S2, including solid product B processing S2-1 and feed liquid A processing S2-2, step S2-1 operates solid product B to obtain the desired final product sodium ferri...

Embodiment 3

[0064] A kind of production method of ferric sodium ethylenediamine tetraacetate, carry out difference according to the method in embodiment 1 and be,

[0065] S1. Preliminary reaction: Add ferric chloride, tetrasodium ethylenediaminetetraacetic acid and water into the reactor at a molar ratio of 1:2:35, react for 2 hours, and the reaction is completed to obtain the raw material solution, and then put the raw material solution at 25 Cooling and crystallization at a temperature of °C for 2 hours, the cooling crystallization process can be realized in a cooling crystallizer, and the first separation operation is performed after the crystallization is completed to obtain the feed liquid A and the solid product B. The first separation operation here can be a filtration operation or is a centrifugal separation operation;

[0066] S2, including solid product B processing S2-1 and feed liquid A processing S2-2, step S2-1 operates solid product B to obtain the desired final product so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com