Automatic spray dust suppression device for overrun of dust concentration

A technology of dust concentration and spray dust reduction, applied in safety devices, mining devices, dust prevention and other directions, can solve the problems of inconvenient use, small spray area, damage to connecting lines, etc., to achieve improved dust reduction efficiency, large coverage area, consumption low water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

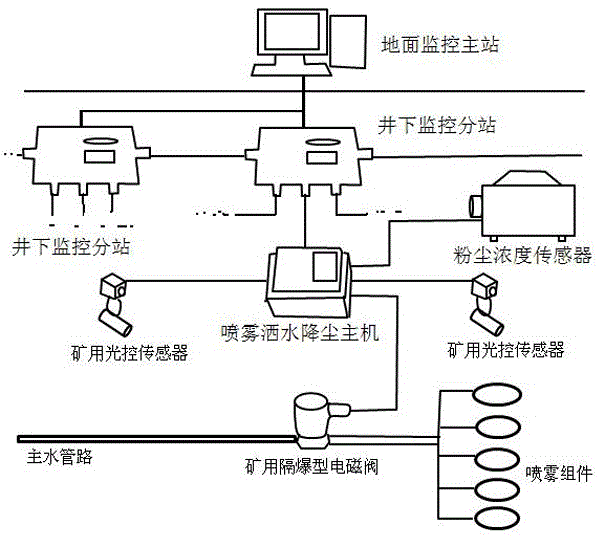

[0013] Such as figure 1 As shown, an automatic spraying and dust suppression device with dust concentration exceeding the limit includes a main ground monitoring station, several underground monitoring sub-stations connected to the ground monitoring main station, several spraying and dust-reducing hosts connected to the underground monitoring sub-stations, and spraying and dust-reducing The dust concentration sensor connected to the host, the mine light control sensor, and the mine explosion-proof solenoid valve, the mine explosion-proof battery valve is installed on the main water pipeline, and its output end is connected to the spray assembly; the spray assembly is installed on the A number of high-pressure nozzles on the water pipe rack are arranged in a spiral fan; the ground monitoring master station manages the underground monitoring sub-stations and the spraying and dust reduction hosts in a hierarchical manner, and regularly reports their status words. All equipment is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com