Five-stroke engine

An engine, five-stroke technology, used in combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems such as inability to fully utilize exhaust gas, alleviate in-cylinder knocking, improve intake density, and optimize combustion. Phase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

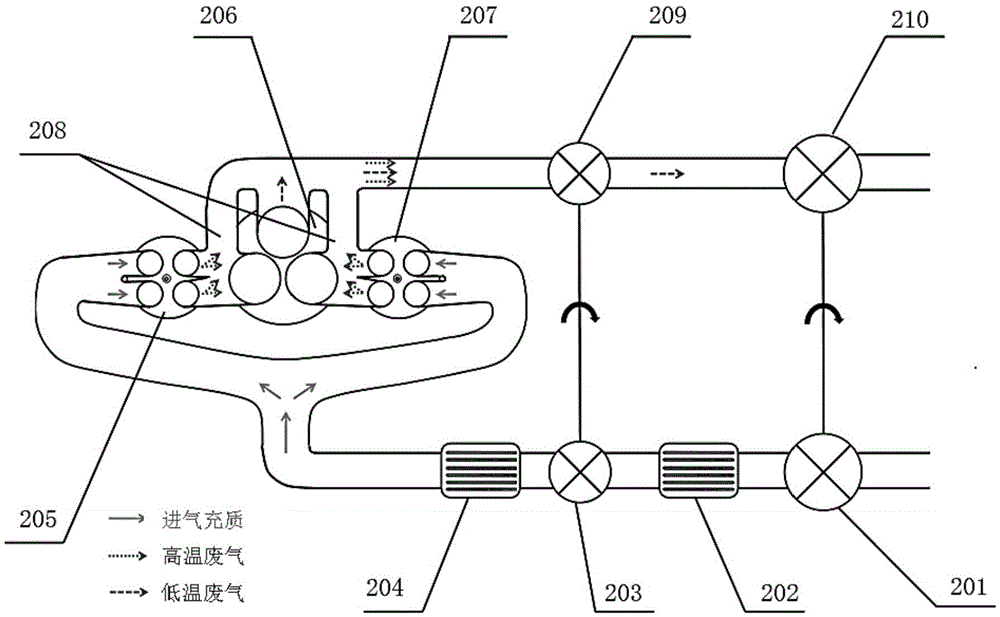

[0020] Such as figure 1 As shown, this embodiment includes: a first cylinder 205, a second cylinder 207, an auxiliary cylinder 206 and a supercharging mechanism, wherein: the intake port and the exhaust port of the first cylinder 205 are connected with the supercharging mechanism, and the first The exhaust port of the cylinder 205 is connected with the intake port of the auxiliary cylinder 206, the intake port and the exhaust port of the second cylinder 207 are connected with the supercharging mechanism, and the exhaust port of the second cylinder 207 is connected with the intake port of the auxiliary cylinder 206. The gas port is connected, and the exhaust port of the auxiliary cylinder 206 is connected with the supercharging mechanism.

[0021] The booster mechanism includes: a high-pressure end turbine 209, a low-pressure end turbine 210, a high-pressure end compressor 203, and a low-pressure end compressor 201, wherein: one end of the high-pressure end turbine 209 is conne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap