A molecular pump and its control method

A control method and molecular pump technology, applied in the direction of pump control, pump, axial flow pump, etc., can solve the problems of high energy consumption, influence of product manufacturing uniformity, and uniformity of pumping efficiency of reaction chamber, etc. Improved control and uniformity, reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

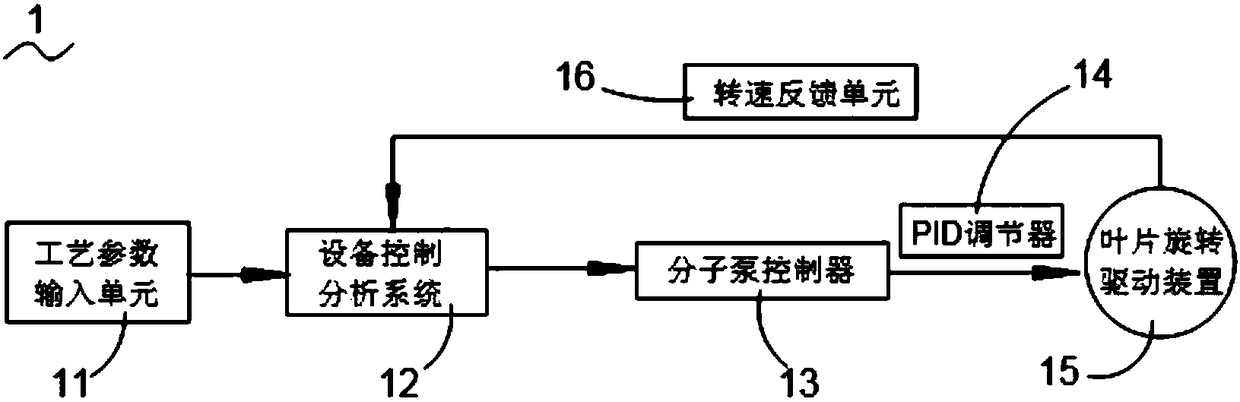

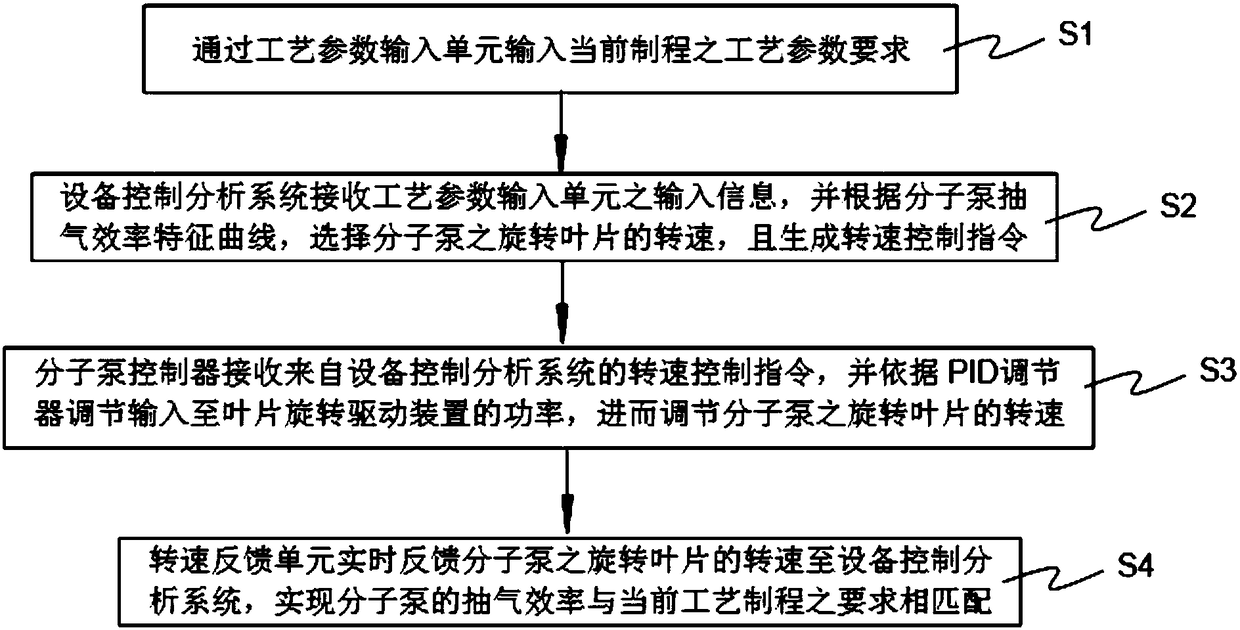

[0023] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following will be described in detail in conjunction with embodiments and accompanying drawings.

[0024] Semiconductor manufacturing requires specific physical and chemical reaction processes in a certain vacuum environment. The acquisition and maintenance of higher vacuum requires the use of molecular pumps. Molecular pumps are widely used in semiconductor manufacturing processes due to their high pumping efficiency and stable operation.

[0025] In the existing molecular pump working mode, the blade speed is maintained at the highest speed, and the upper-stage swing valve is adjusted to achieve pressure control under different process conditions. Obviously, the above-mentioned molecular pump has the highest energy consumption in the working mode. At the same time, because the pumping efficiency of the molecular pump cannot be fully utili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com