Lateral-directional single-hoop mounting structure for airplane gas cylinder

A technology of installation structure and horizontal direction, which is applied in the direction of mechanical equipment, gas/liquid distribution and storage, container discharge methods, etc., to facilitate disassembly and inspection and daily maintenance work, improve maintainability and safety, and maximize flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

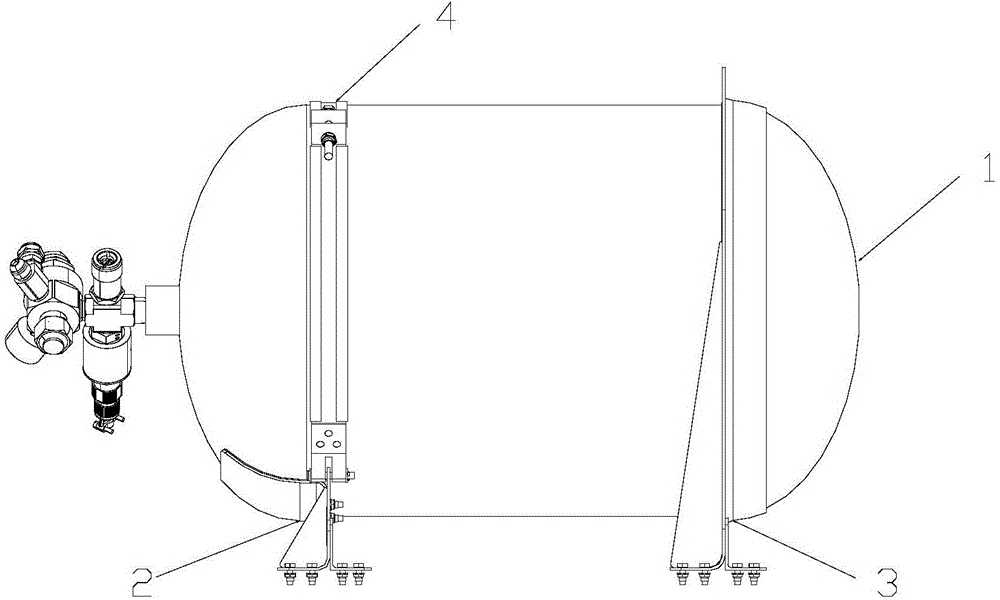

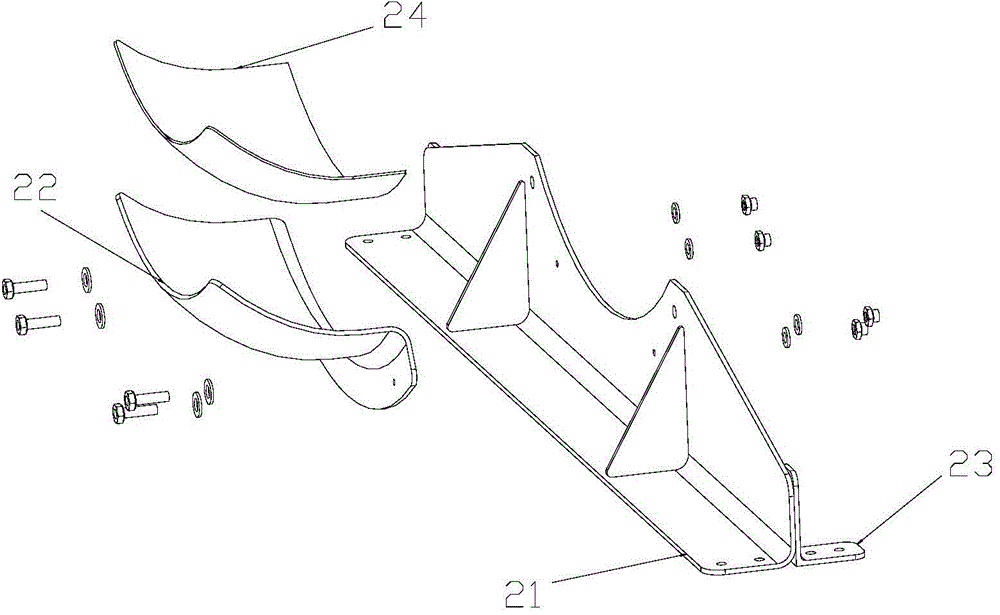

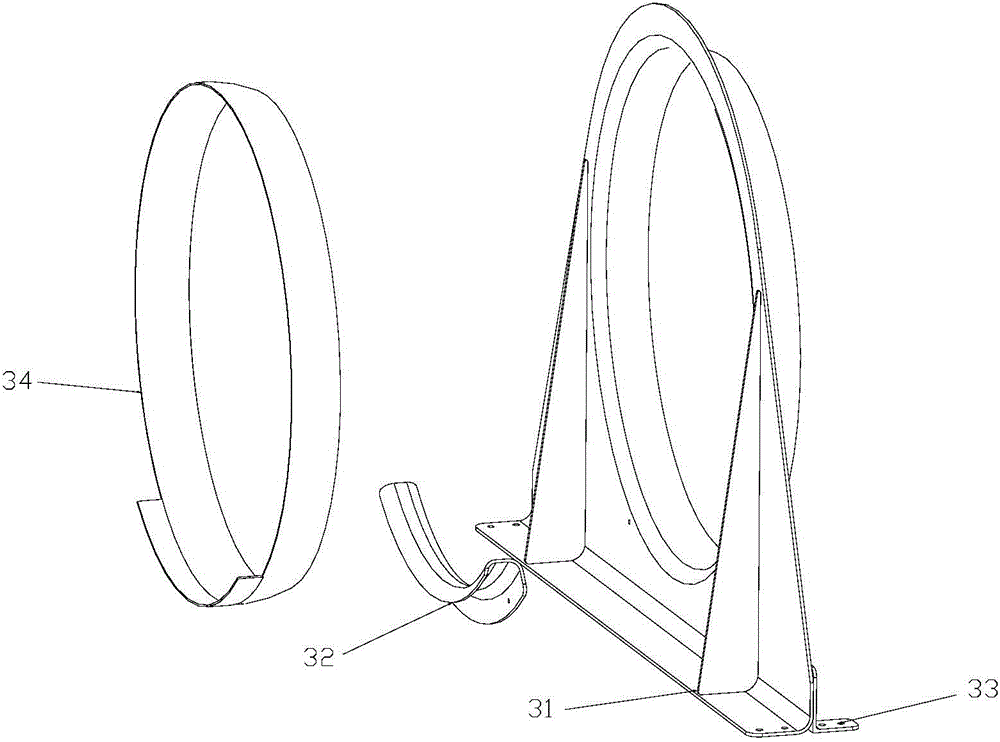

[0013] An aircraft gas cylinder horizontal direction single clamp installation structure, such as figure 1 , 2 , 3, it consists of a gas cylinder 1, a front bracket 2, a rear bracket 3, and a clamp 4. The neck of the gas cylinder 1 is firmly supported by the front bracket 2 and clamped by the clamp 4 to prevent its displacement. The bottom of 1 is limited by rear bracket 3 to prevent its axial and circumferential displacement. Front support 2 is made up of base 21, bowl holder 22, L support 23 and buffer pad 24, bowl holder 22 is connected with base 21 by screws, and the supporting surface of bowl holder 22 is a two-dimensional curved surface shape, which is completely consistent with the shape of cylinder 1 shoulder. Fitting to the maximum extent to ensure that the contact force with the cylinder surface is more uniform under overload conditions, and the cylinder is not worn while limiting; at the same time, there is a buffer pad 24 between the bowl holder 22 and the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com