A method for controlling rock or concrete breakage patterns

A concrete and concrete roof technology, which is applied in earthwork drilling, blasting, wellbore/well components, etc., can solve problems such as cracks and broken modes that are difficult to control, increase workload and construction cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

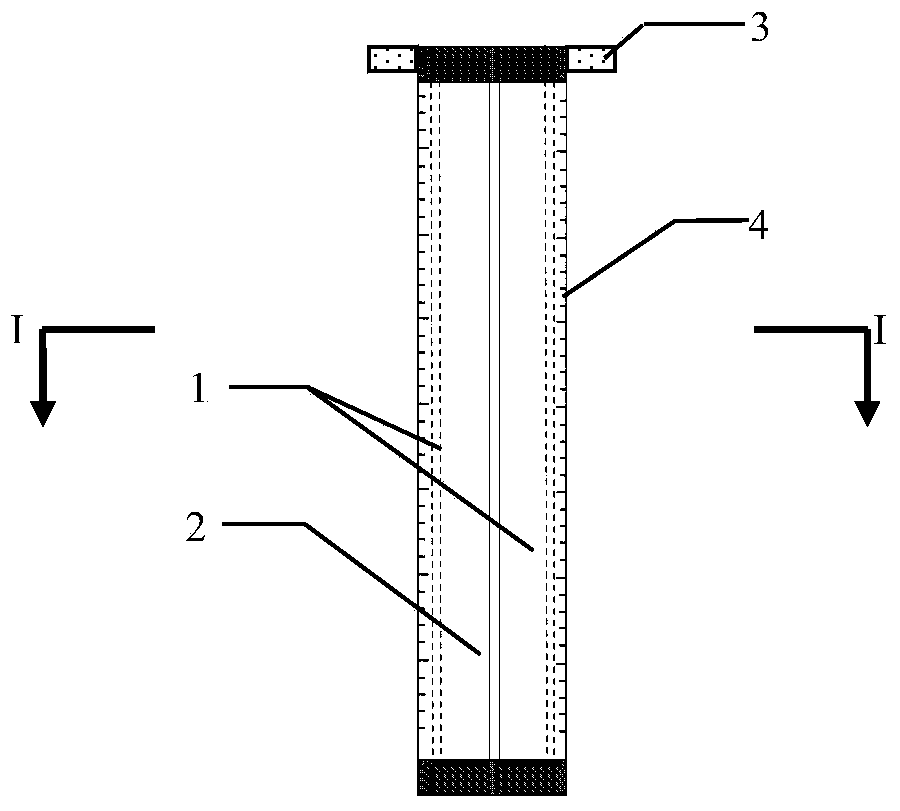

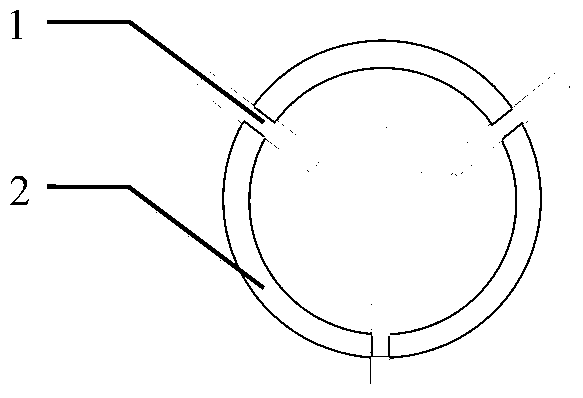

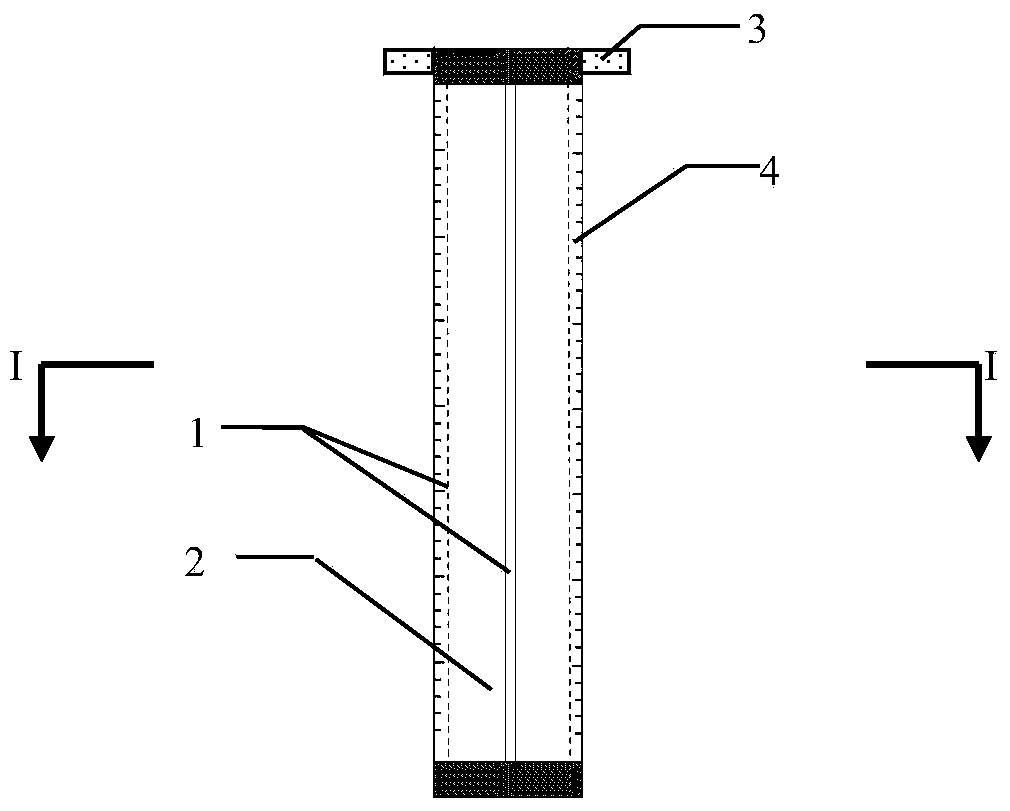

[0015] The patent of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

[0016] The purpose of crushing needs to be clarified before construction. If the crushed body is expected to be crushed in a plum blossom shape, the hole layout method should be a plum blossom shape, and the selected guide devices are three-way guide devices and four-way guide devices. Drilling, place the guide device inside the drill hole, place the three-way guide device on the top and bottom two rows of drill holes, and place the four-way guide device on the drill hole in the middle position, such as Figure 5 As shown, the cutting direction of the cylinder is the same as the expected crack propagation direction, then design the mixing ratio, stir the static breaking agent and water evenly and pour it into the drilling hole, observe the slurry pouring situation through the scale line on the side wall of the cylinder, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com