Web manufacturing method, charge control method, and charge control device

A manufacturing method and electrification control technology, which can be applied to devices for coating liquid on surfaces, winding strips, static electricity, etc., and can solve the problems of inability to configure the eliminator, inability to set the eliminator, and low electrification potential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

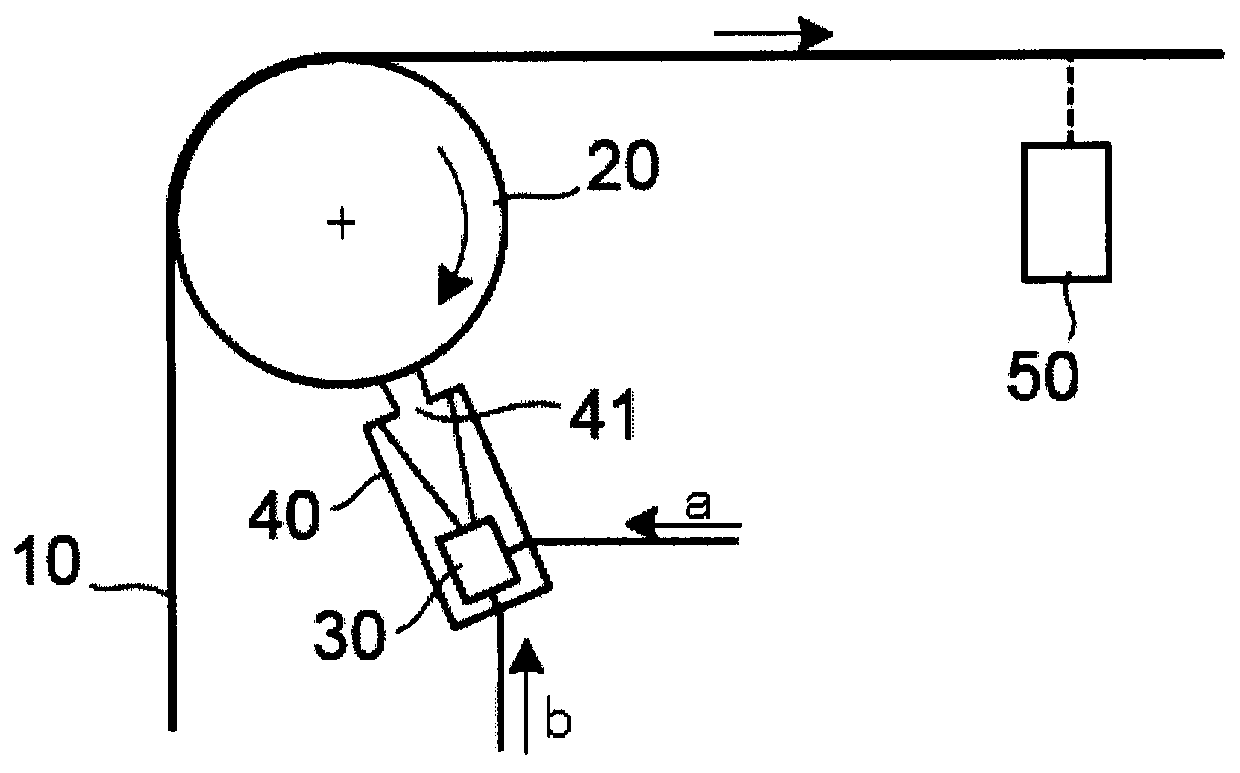

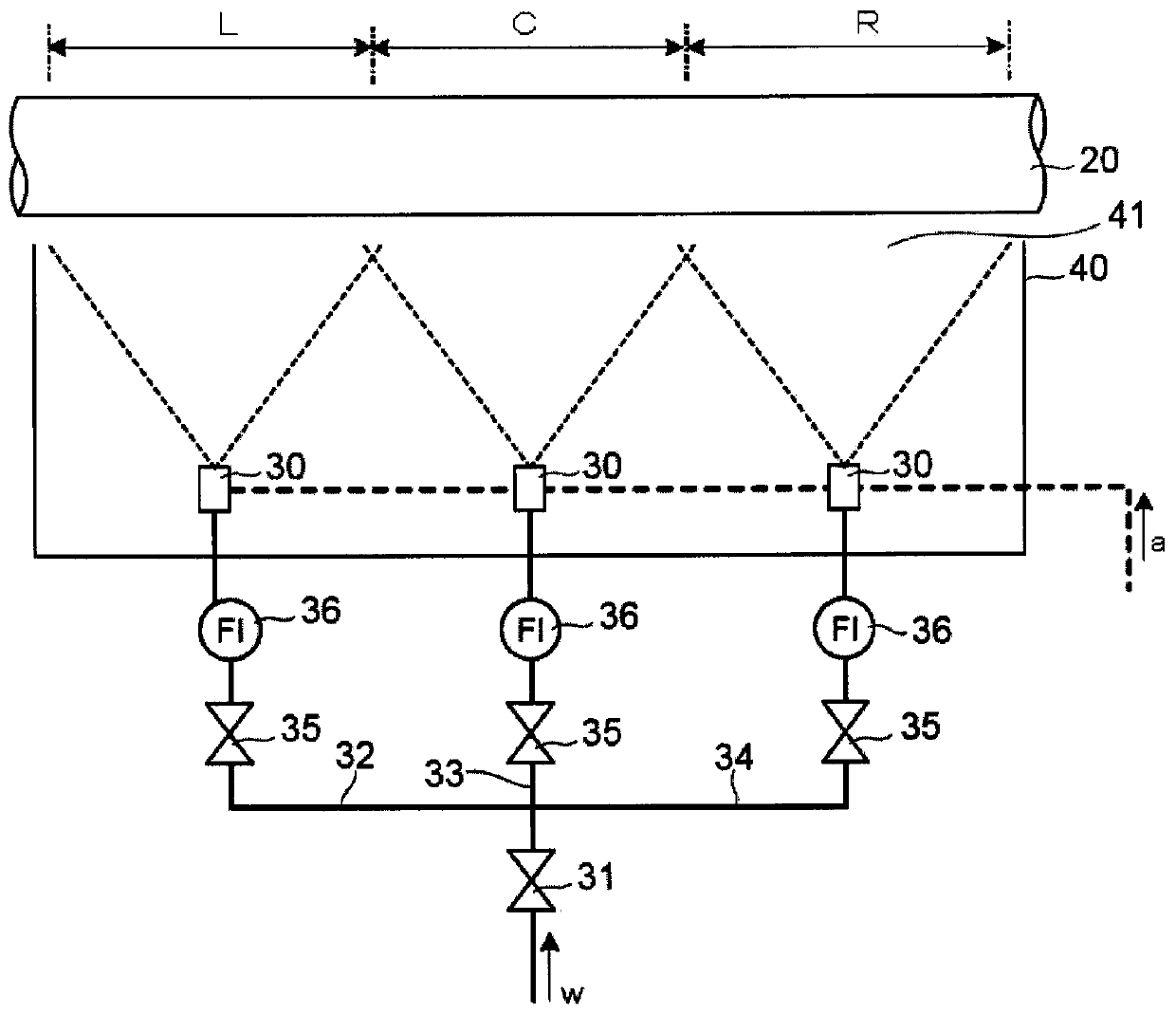

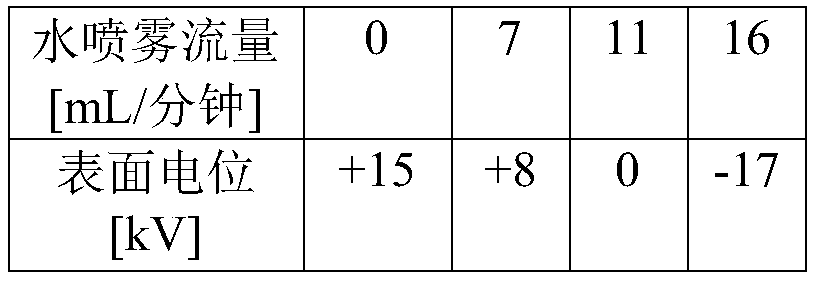

[0045] to assemble figure 1 device shown. Here, a soft polyethylene sheet (manufactured by Kokugo Co., Ltd.) with a thickness of 30 μm was used as the coil 10 , and a metal roller with a diameter of 150 mm and whose surface was hard chrome-plated was used as the transport roller 20 . A two-fluid nozzle (model number: SCBIMV80005S) manufactured by Ikeuchi Co., Ltd. was used as the spray nozzle 30 which is a sprayer. By using tap water as the liquid b for charge control, and supplying the tap water and air a to the spray nozzle 30 , water can be sprayed on the transport roller 20 . The conveying roller 20 was rotated and the web 10 was conveyed at a speed of 30 m / min. Then, the surface potential of the web 10 was measured by the potentiometer 50 provided on the downstream side of the transport roller 20 while changing the presence or absence of water spray and the flow rate of the water spray. The results are shown in Table 1.

[0046] As can be seen from Table 1, when water...

Embodiment 2

[0050] The same procedure as in Example 1 was performed except that a glass cover roller was used as the transport roller 20 and 1,2,4-trichlorobenzene was used as the liquid b for charge control. The results are shown in Table 2. As can be seen from Table 2, when the liquid is not sprayed, the surface potential of the coil 10 is negative at approximately -9 kV, but when the liquid is sprayed, the surface potential changes to a positive direction. When the spray flow rate of the liquid is set at 10 mL / min, the surface potential shifts to the positive side and becomes about -5 kV, and when the spray flow rate is set at 15 mL / min, the surface potential becomes almost 0 kV. That is, by setting the spray flow rate of the liquid to 14 mL / min to 16 mL / min, frictional electrification of the coil 10 can be prevented. If the spray flow rate is further increased to 20 mL / min, the surface potential can be shifted to +8 kV. It can be seen that even when the web 10 is negatively charged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com