In-line production of silica for retention purpose

A technology of silica and retention aids, applied in the direction of addition of retention aids, inorganic chemistry, silicon compounds, etc., can solve the problems of unfriendly transportation, expensive environment, low solid content, etc., and achieve the improvement of colloidal instability and improvement The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

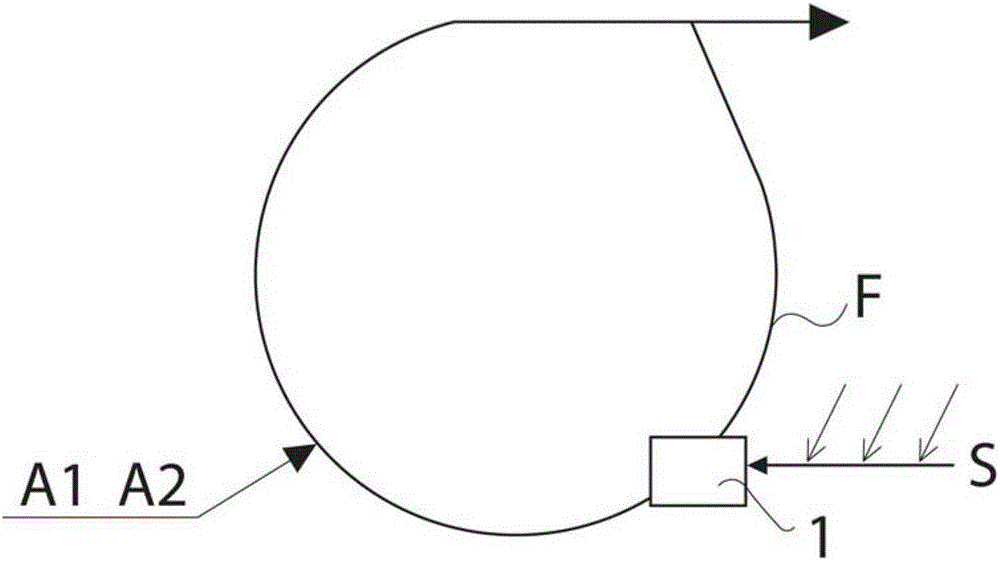

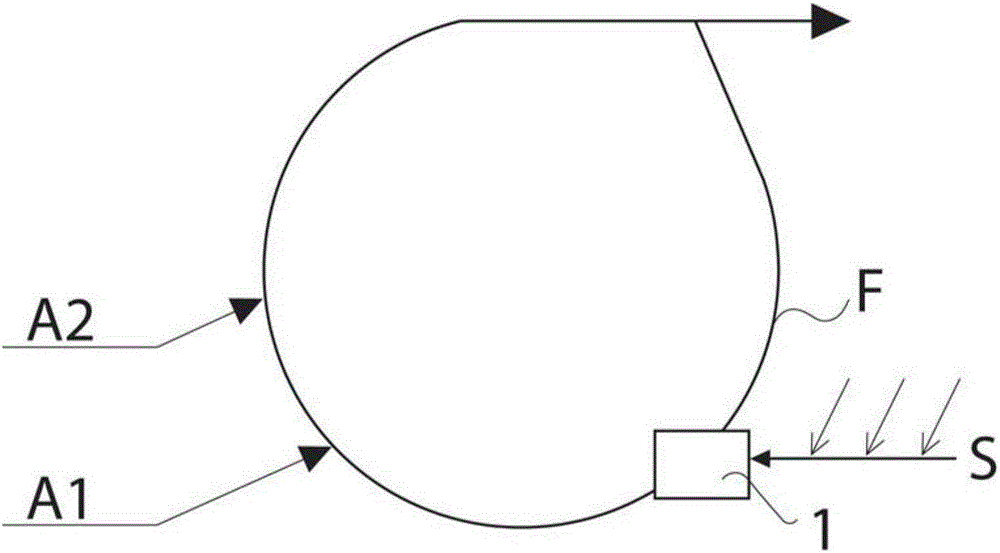

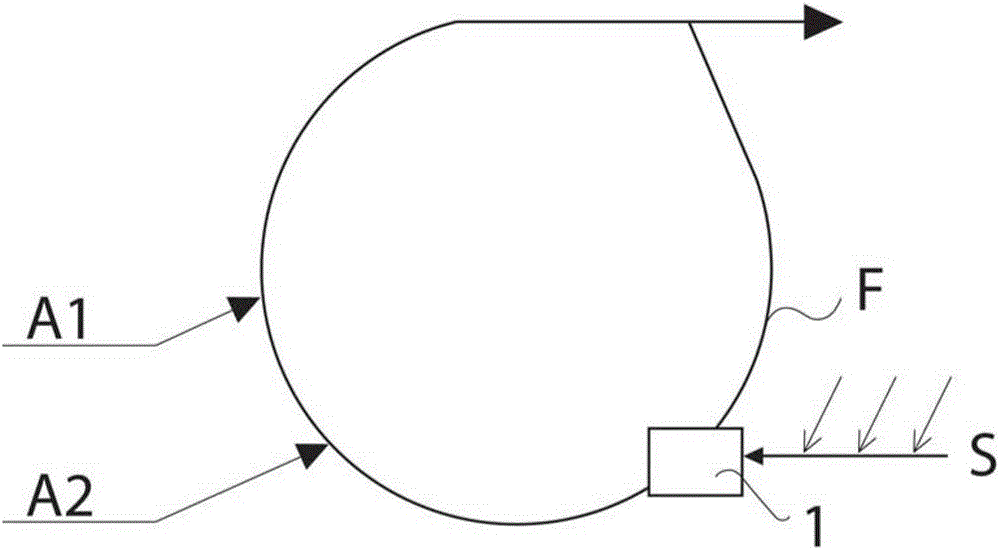

[0040] "In-line production" means that the retention aid is at least partially formed directly in the papermaking stock stream, rather than being produced separately from the papermaking process.

[0041] Different types of dosing systems that may be used in conjunction with the present invention are disclosed in eg WO20111 / 110744, US2007258316, WO0225012, US2007258315 and US20080011788.

[0042] According to the present invention, there is provided an in-line production process in which additives such as sodium silicate and acidic medium are fed into the short cycle of the paper machine, ie into the fiber web or paper stock. When forming silica-based retention aids according to the invention, the reaction between acid and silicate to form silicic acid and further polymerization to colloidal silica can take place in the stock suspension. Alternatively, also within the scope of the present invention, the silicic acid can already be formed in the dosing device, but the polymeriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com