Transparent double-measurement-system static force level gauge and use method thereof

A static level and measurement system technology, applied in the direction of hydrostatic pressure equalization, can solve the problems of inaccurate data zero jump, unfavorable on-site operation and installation, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

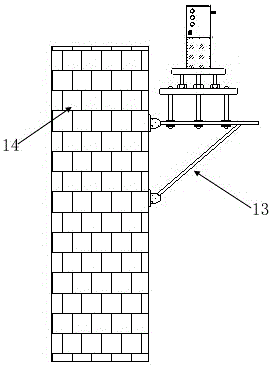

[0024] Below in conjunction with accompanying drawing, the present invention will be further described:

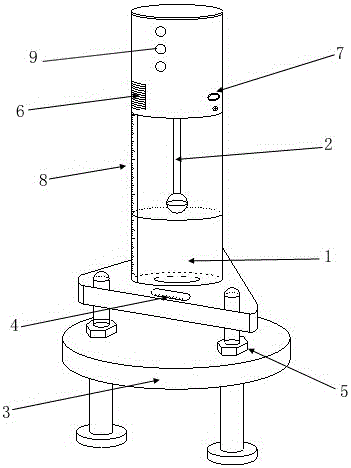

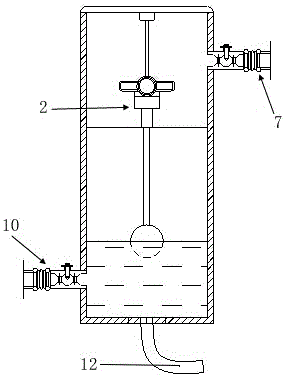

[0025] like figure 1 , 2 As shown, a static level with a transparent dual measurement system includes a transparent liquid storage cylinder 1, a magnetostrictive liquid level gauge 2, a leveling base 3, a leveling system, a circuit module 6, a vertical displacement indicator light 9, and a transparent liquid storage tank. The outer wall of the cylinder is provided with a surface measuring scale 8 (surface resolution is 1mm), and an air pressure balance hole 7 is provided above the transparent liquid storage cylinder, and an air pressure balance valve can be connected to the air pressure balance hole, and a liquid inlet is provided under the transparent liquid storage cylinder. Hole 10, the liquid inlet can be externally connected to the liquid inlet valve, and the bottom of the transparent liquid storage cylinder is provided with a liquid communication pipe 12; the magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com