Eddy current flaw detection device and bearing detector using same

A detection device and eddy current flaw detection technology, which is used in measurement devices, mechanical bearing testing, instruments, etc., can solve the problems of complex positioning mechanism, reduced detection efficiency, detection head damage, etc., to achieve high adjustment accuracy, improve detection efficiency, and improve adaptability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

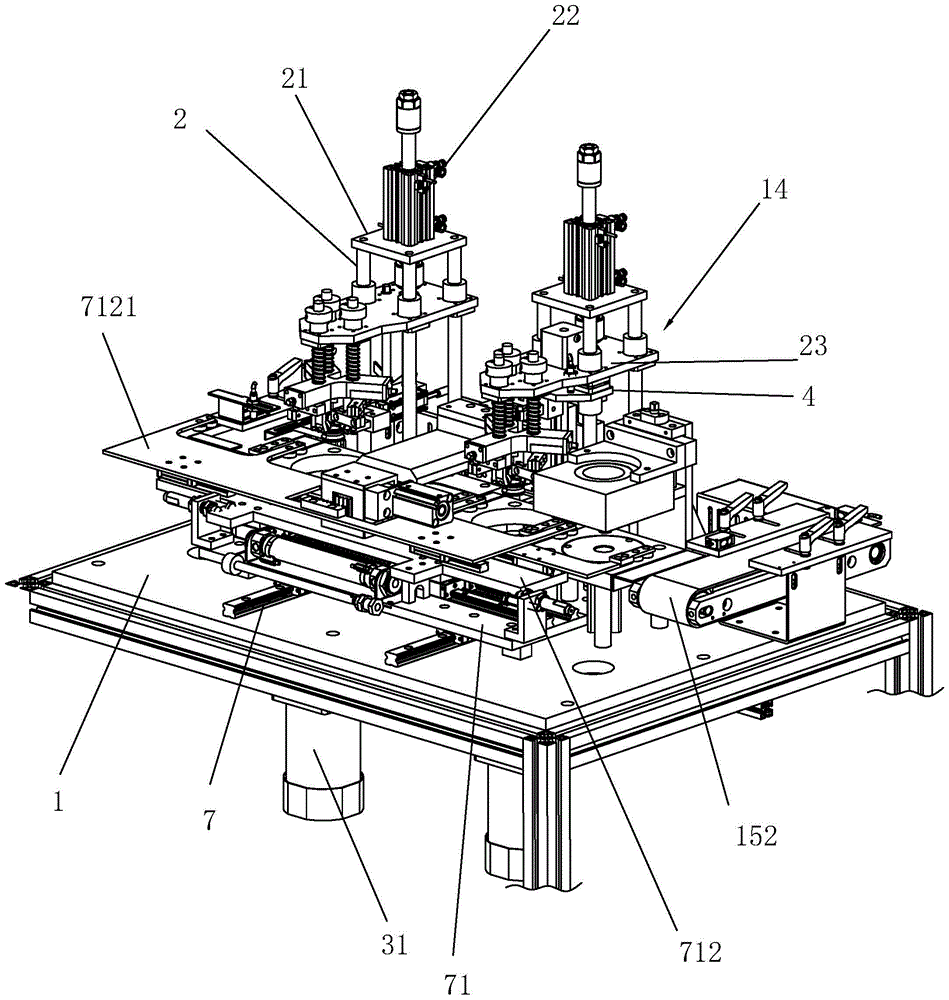

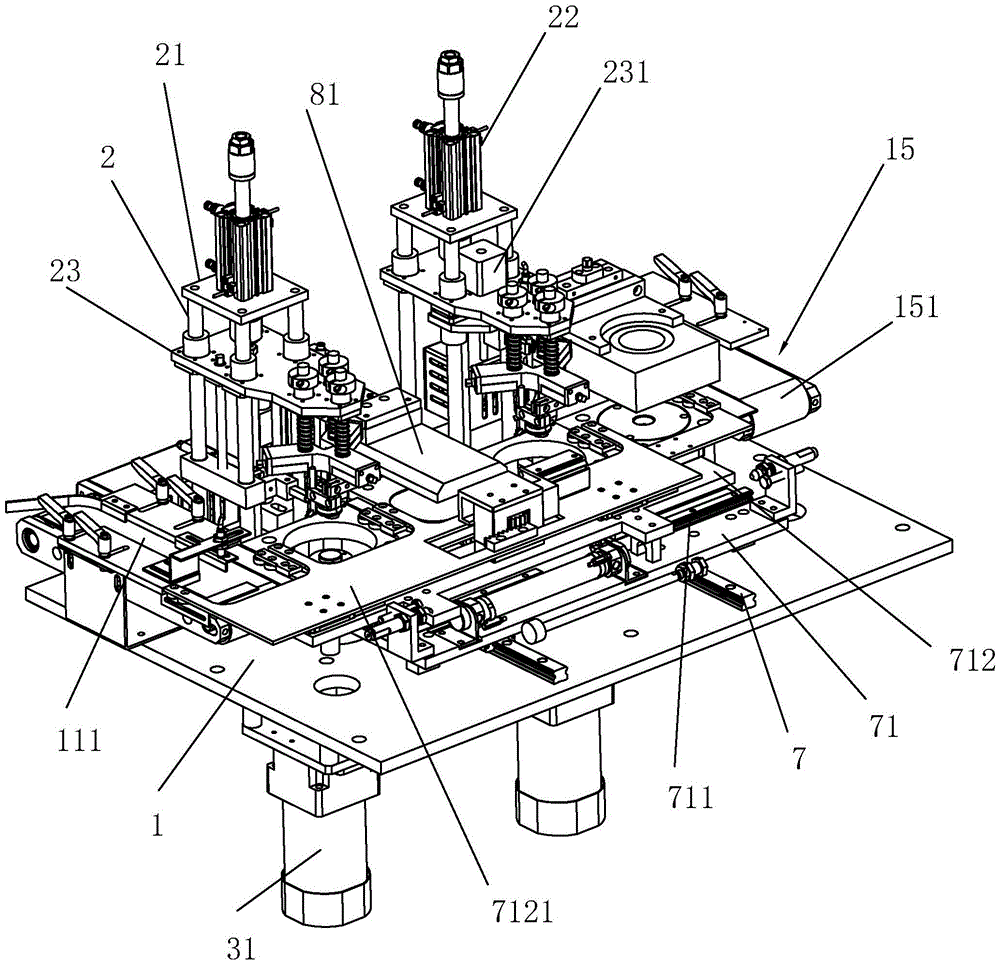

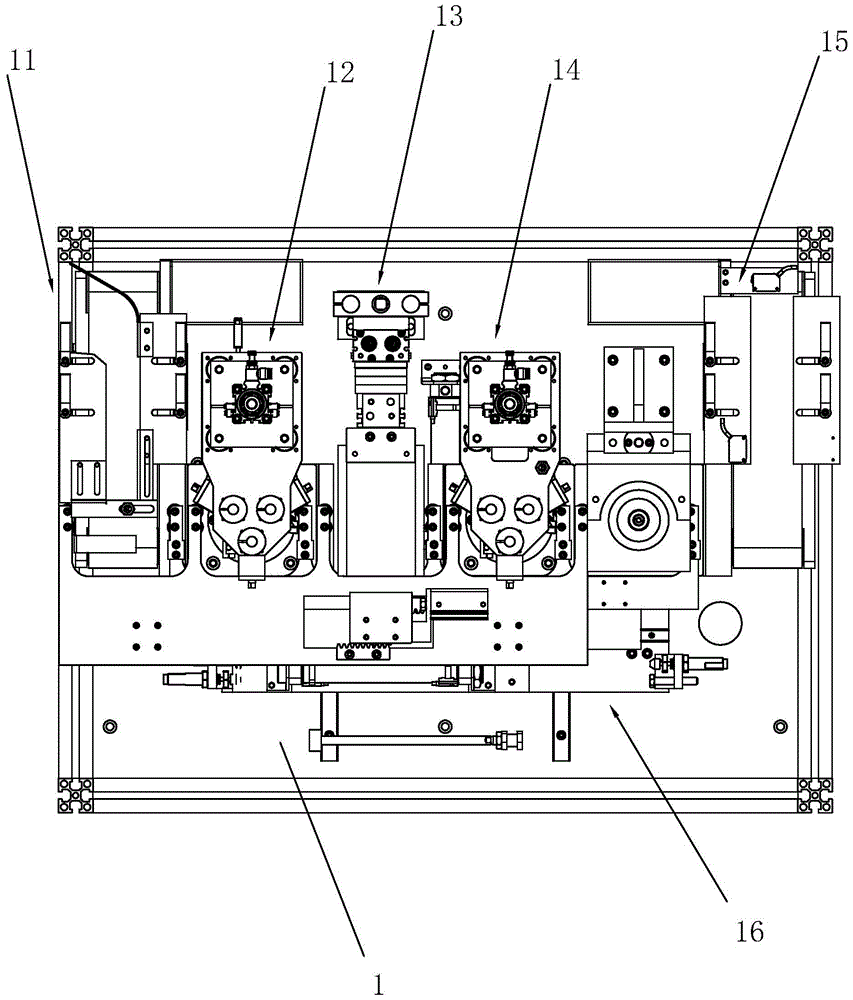

[0039]An eddy current flaw detection device, comprising a workbench 1, on which a pan plate 3 for placing a bearing 9 to be tested is rotated, and a drive motor 31 is provided at the bottom of the workbench 1 to drive the pan plate 3 to rotate, The output shaft of the driving motor 31 is connected with the flat rotating plate 3, and an annular groove 32 is arranged on the flat rotating plate 3. The bearing is placed at the center position of the flat rotating plate 3, and the annular groove 32 is set. When the detection head 61 moves to the outermost position of the outer ring At the lower end, the annular groove 32 can prevent the detection head 61 from colliding with the pan plate 3. After the bearing 9 to be detected is pressed on the pan plate 3, the drive motor 31 drives the pan plate 3 to rotate, and the detection head 61 is vertically synchronized. Mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com