Detection fixture for ozone machine power panel

A technology for detecting fixtures and power boards, which is applied in the direction of the measuring device casing, etc., can solve the problems of personal safety threats to operators, unsafe detection equipment, and reduced production efficiency of enterprises. It achieves low professional requirements, simple structure, and convenient control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

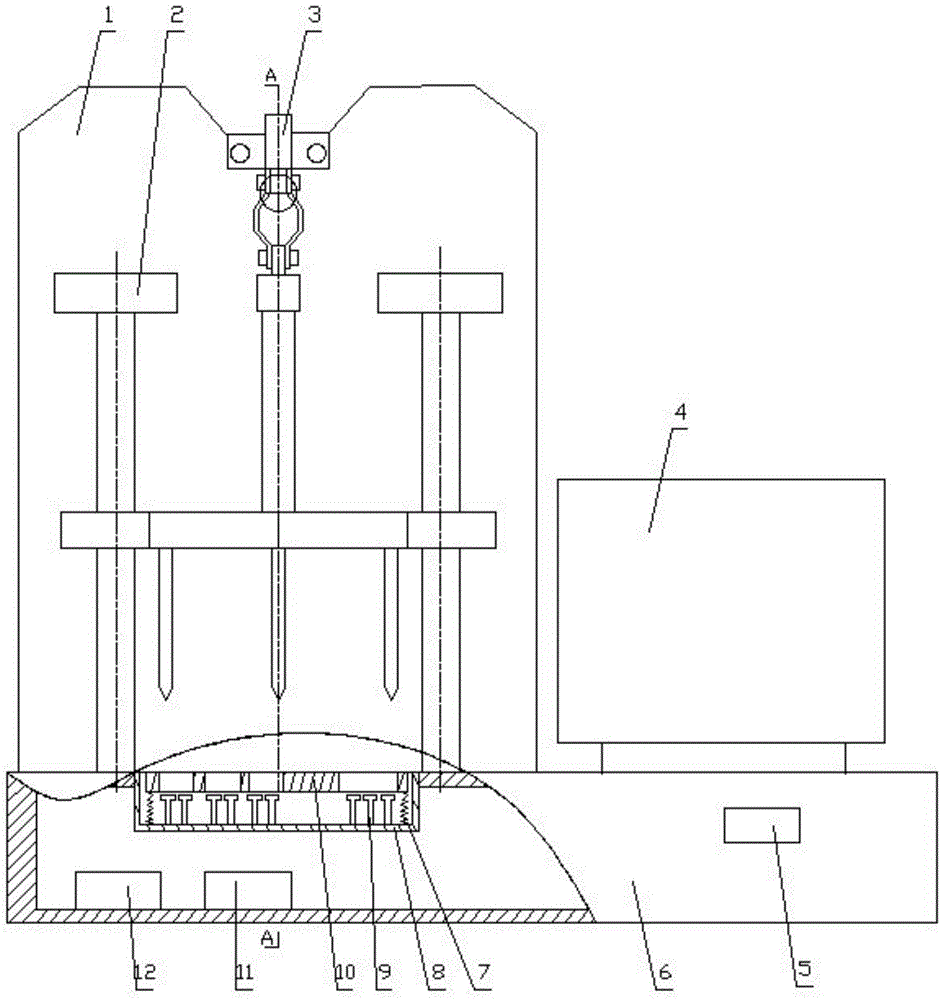

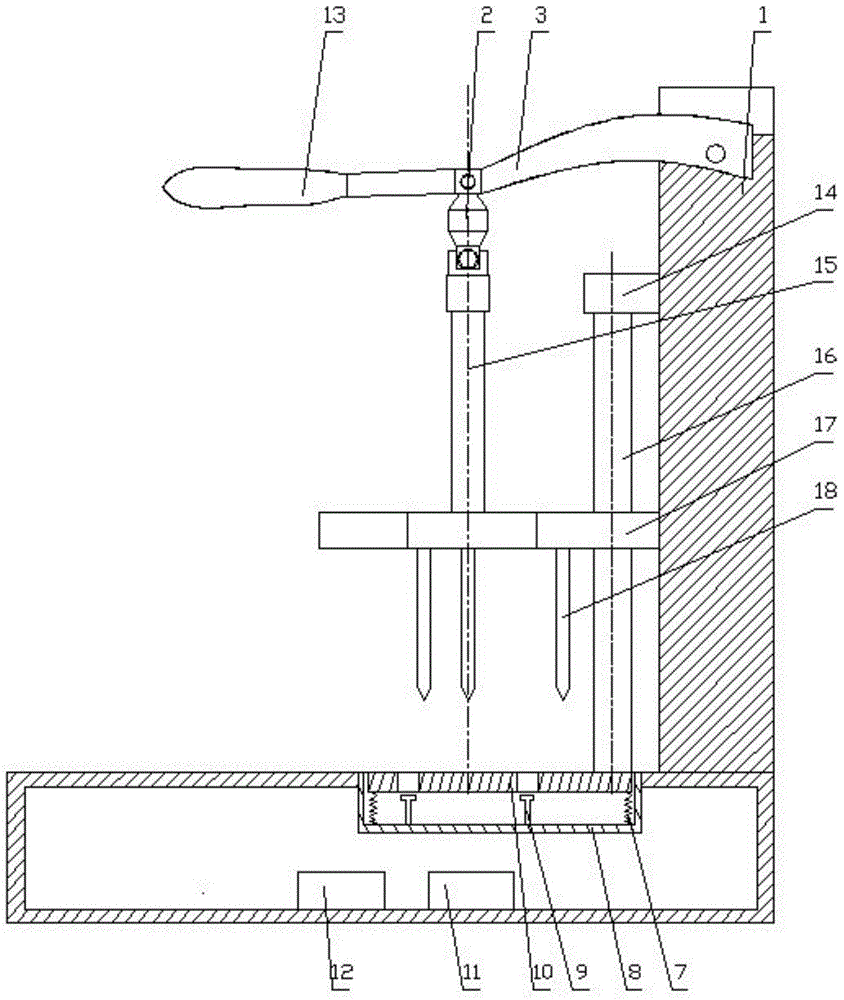

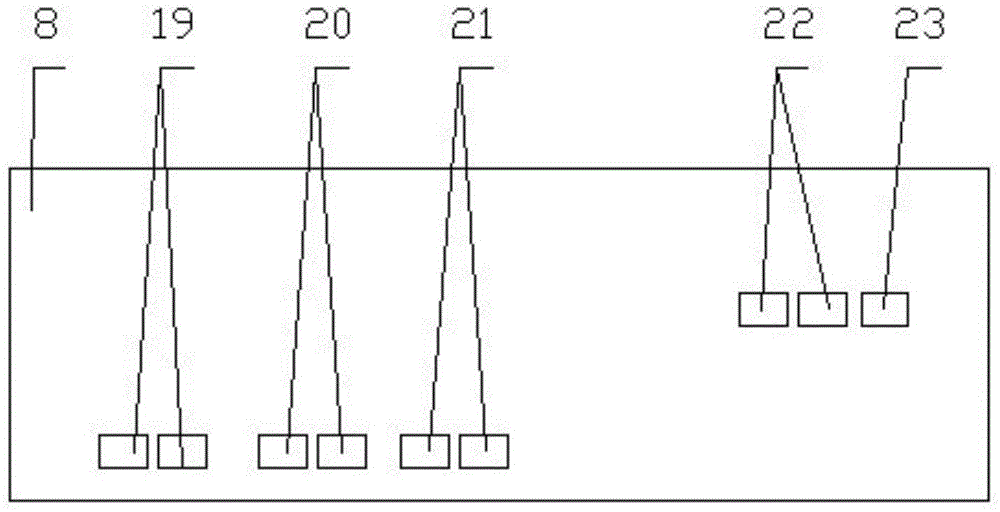

[0021] A detection fixture for an ozone machine power board, such as figure 1 , such as 2 and image 3 As shown, the fixture includes a power switch 5, a frame 1, an air pump 12, an ozone generator 11, a crank handle 3, a platen mechanism 2, a needle bed 8, a pallet box 6, a controller and a display screen 4, and the machine A hollow pallet box is formed in the horizontal direction below the frame, an air pump and an ozone generator are arranged in the pallet box, a power switch is arranged on the outer surface of the pallet box, and a There is a controller and a display screen; the other side of the upper su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com