Sliding cutting device suitable for novel fusion splicer

A technology of optical fiber fusion splicing machine and cutting device, which is applied in the field of optical fiber fusion, can solve the problems of high processing cost, complicated fusion steps, and low efficiency, and achieve the effects of improving work efficiency, low cost, and reducing operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

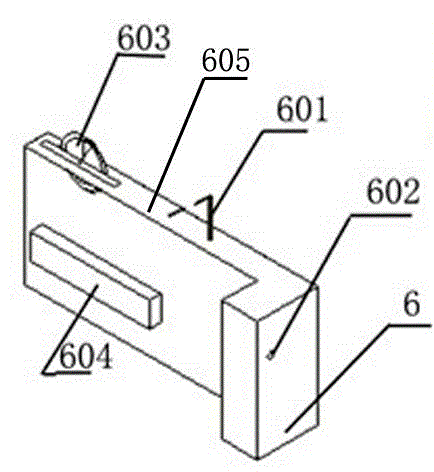

[0019] A sliding cutting device suitable for a new type of optical fiber fusion splicer, characterized in that an optical fiber cutting blade 603, a discharge electrode 601, and a stroke control mechanism are arranged on the moving slider 6; the linkage mechanism 5 includes a positioning groove, a spring, and a state control slider , the state control slider is installed on the motion slider; the stroke control mechanism determines the position of the fiber cutting blade, and the hammer breaks the scratched fiber under the drive of the linkage mechanism.

[0020] Such as figure 1 As shown, a protruding structure 604 is provided on the side of the moving slider to make the moving slider move stably in the sliding cavity of the frame. The moving slider is processed as a metal piece; the positioning pin 602 for determining the discharge electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com