Small-volume and high-current temperature controller

A high-current, thermostat technology, applied in the direction of circuits, electric switches, electrical components, etc., can solve the problems of bulky thermostats, complex internal structures, overheating and burnout, etc., to achieve heat dissipation and cooling, and work stability Strong, increasing contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] In this specification, in order to clearly describe the installation orientation of each component, orientation concepts such as left, right, up, and down are cited. However, the above-mentioned concept of orientation is relative, and it is only for the convenience of clearly describing the positional relationship between the various components, and does not affect the orientation of the product during actual installation.

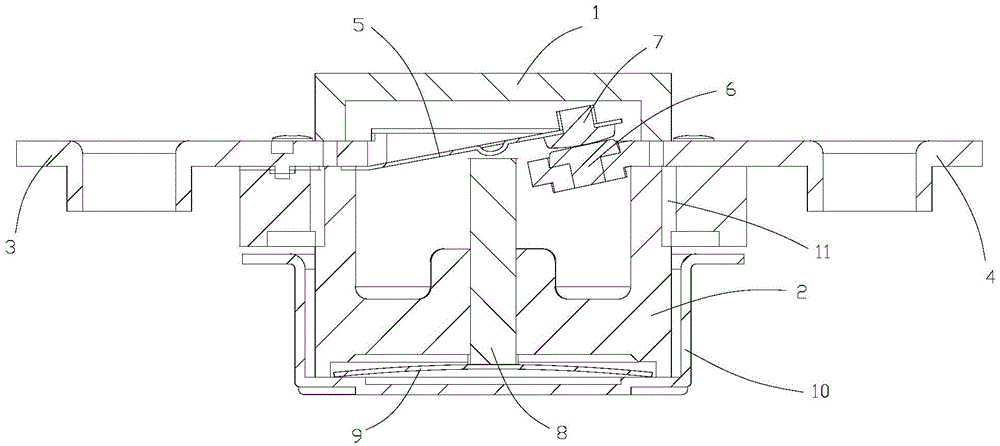

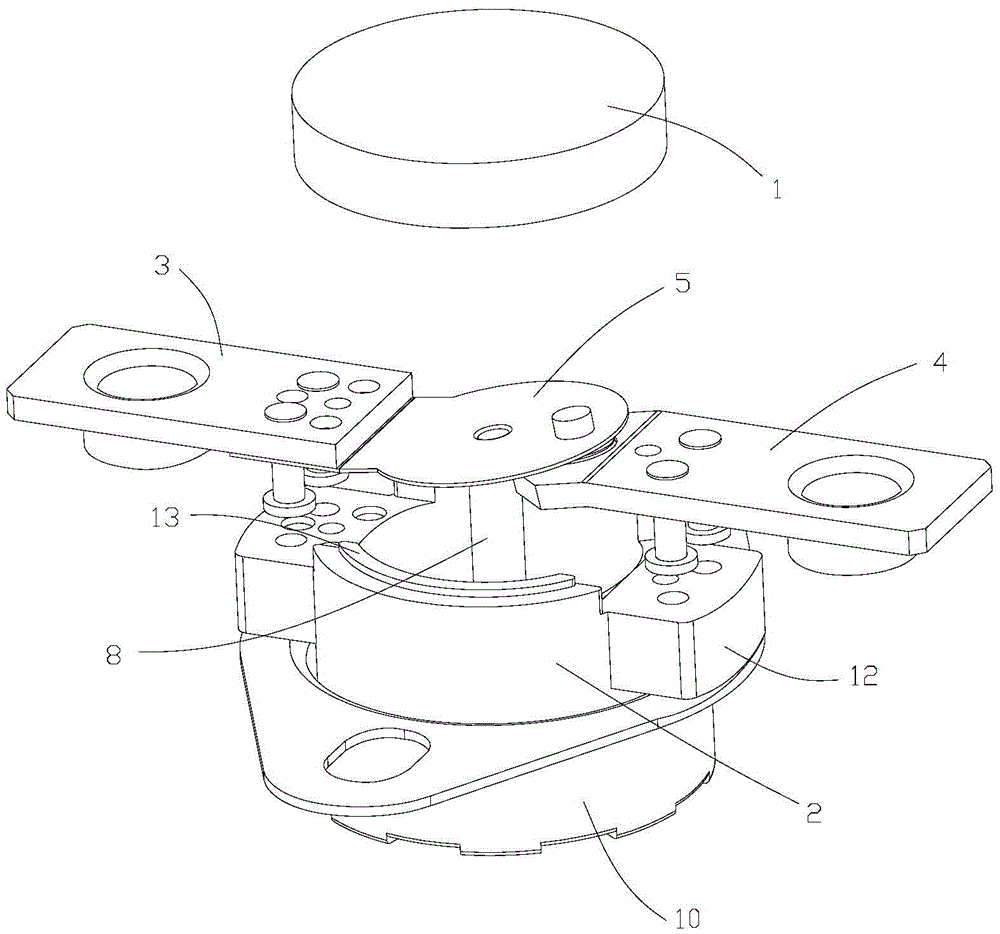

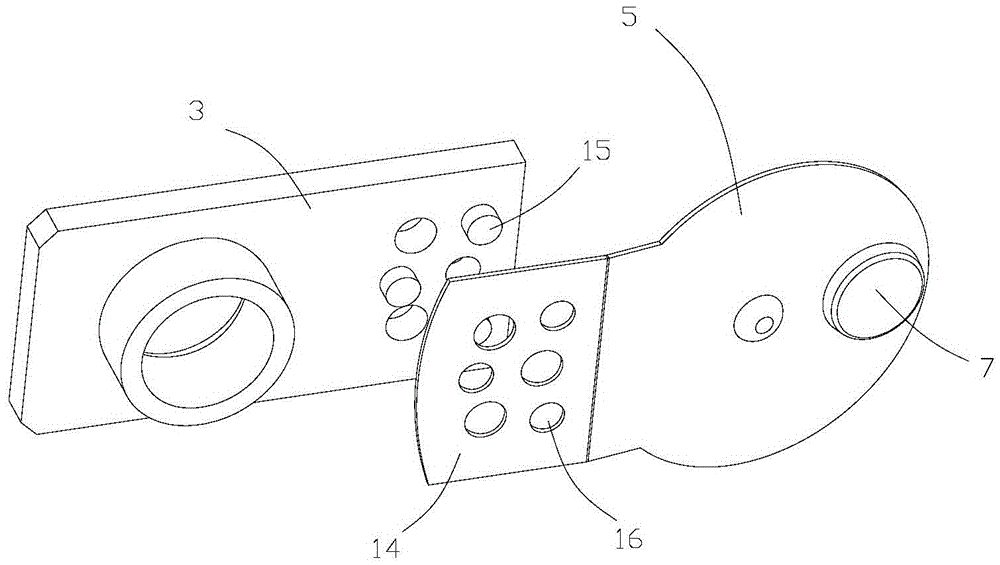

[0038] see Figure 1 to Figure 4 , this embodiment discloses a small-volume high-current thermostat, including a top cover 1, a housing 2, a first terminal 3, a second terminal 4, a reed 5, a fixed contact 6, a moving contact 7, a ceramic Rod 8, disc 9 and cover 10; shell 2 is a hollow cylinder, and its left and right sides are provided with outwardly protruding terminal mounting parts 12, and the bottom of shell 2 is provided with a circular barrier, the barrier The middle part is provided with a guide hole; the two terminal mounting parts 12 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com