Array substrate and manufacturing method thereof

An array substrate and substrate substrate technology, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor/solid-state device components, semiconductor devices, etc. The effect of reducing the risk of cracking, enhancing mechanical strength, and strong process compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings, wherein like reference numerals correspond to like elements. However, the present invention has many different embodiments, and it should not be construed as limiting the present invention to the described embodiments; but only by providing the embodiments of the present invention, so that the present disclosure will be comprehensive and complete, and will fully inform those skilled in the art. to convey the concept of the invention.

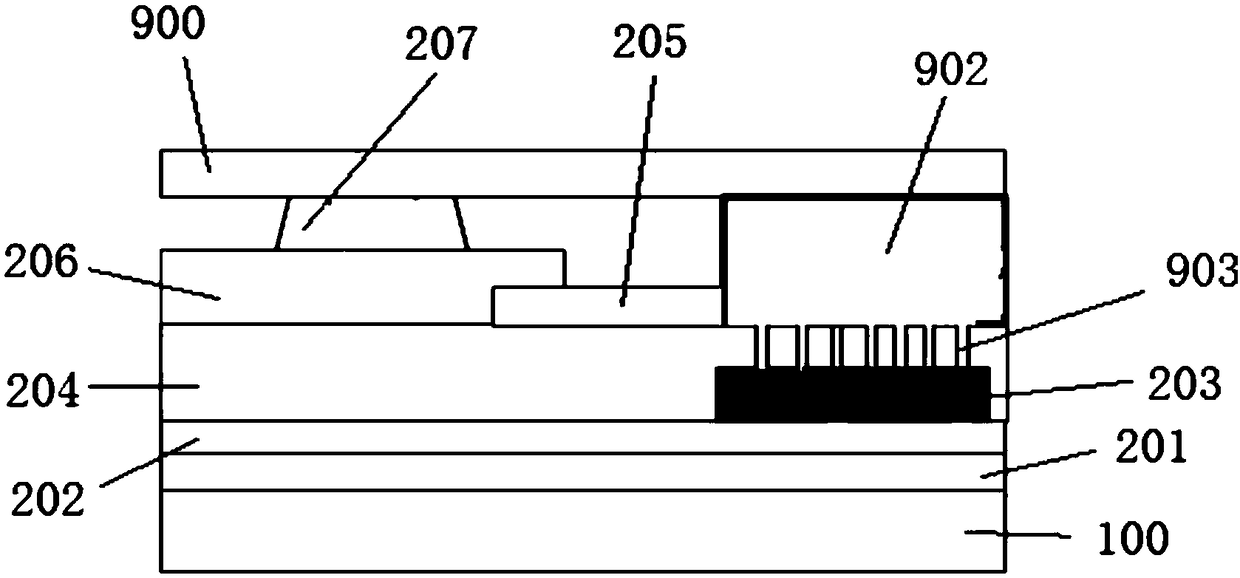

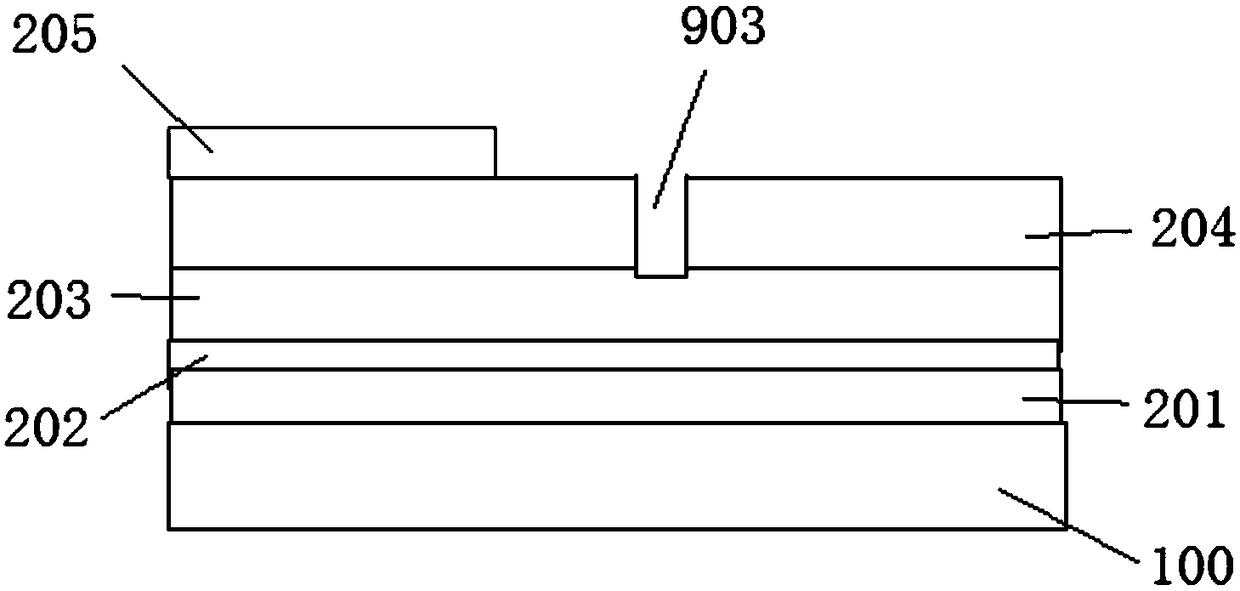

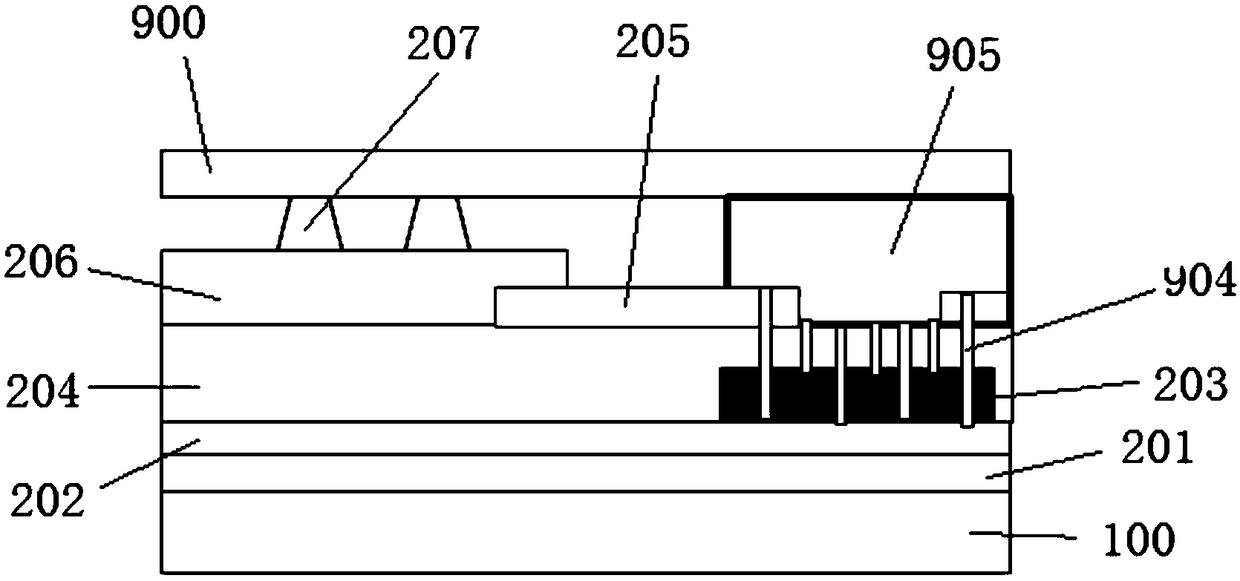

[0033] image 3 An embodiment of the array substrate provided according to the present invention is shown, which includes: a display area and a packaging area, the packaging area includes multiple functional layers, and the packaging area includes: a through hole 904, the through hole Through at least one functional layer, the encapsulation glue flows in through the through hole; the groove 905 is arranged above at least pa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap