I type tri-level drive circuit

A drive circuit, three-level technology, applied in electrical components, electronic switches, pulse technology, etc., to achieve the effect of suppressing collector voltage spikes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

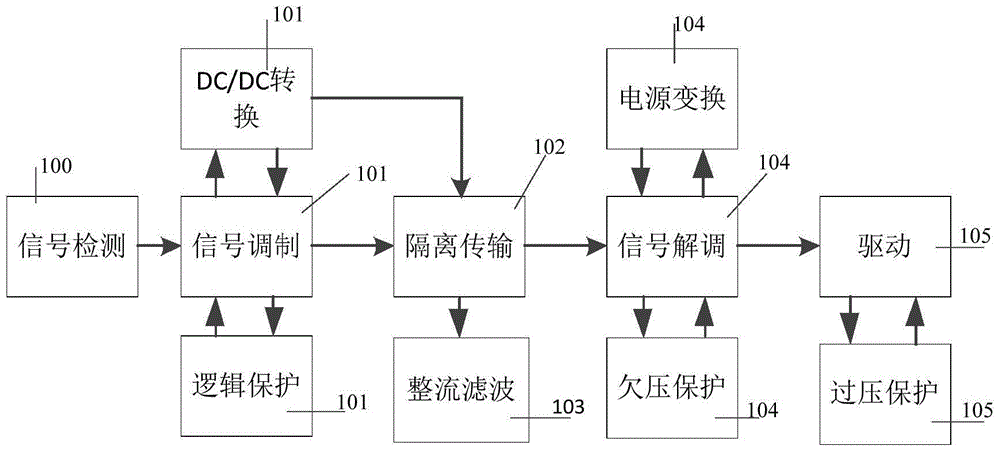

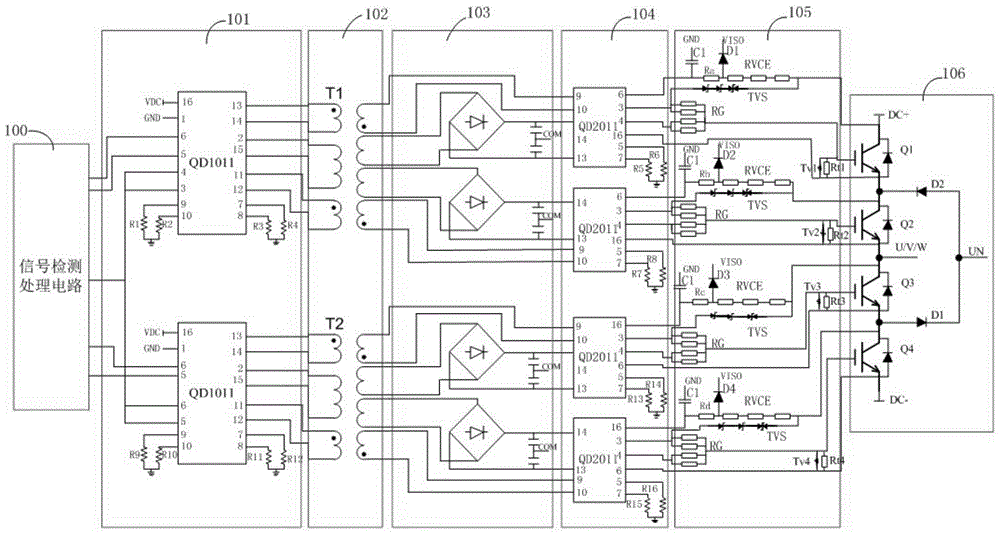

[0041] Such as figure 1 As shown, the I-type three-level drive circuit of this embodiment includes in turn:

[0042] A signal detection circuit 100, which detects the input signal timing of the circuit to prevent damage to the IGBT caused by the abnormal signal timing;

[0043] A signal modulation circuit (a part of 101), which modulates the signal input by the signal detection circuit into a signal that can pass through the isolation transmission device;

[0044] A DC / DC conversion circuit (a part of 101), through the signal modulation circuit, the output frequency of the conversion circuit is adjustable, and according to the power requirement of driving the IGBT, an external MOSFET can be connected to increase the output capacity;

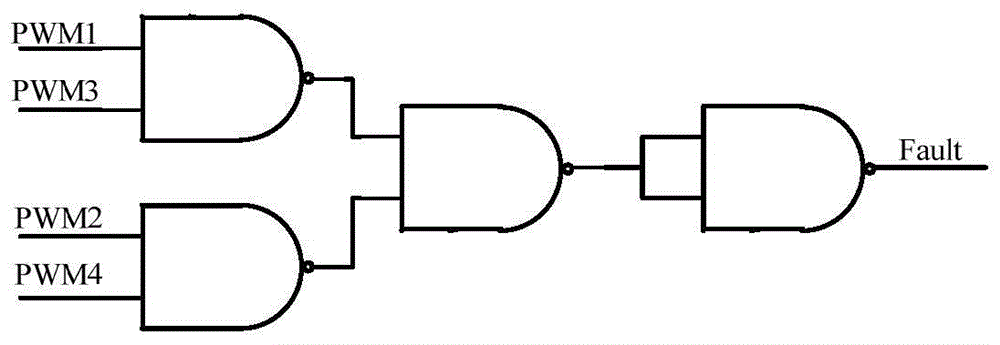

[0045] A logic protection circuit (a part of 101), which monitors external IGBTs or internal faults in real time, and acts quickly to protect IGBTs when a fault occurs;

[0046] An isolated transmission circuit 102, which transmits the modulate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com