Production method for fused sheet and production method for absorbent article

A manufacturing method, a technology of sheet welding, applied in the fields of absorbent pads, medical science, clothing, etc., can solve the problem of how to fix the unrecorded film superimposed body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

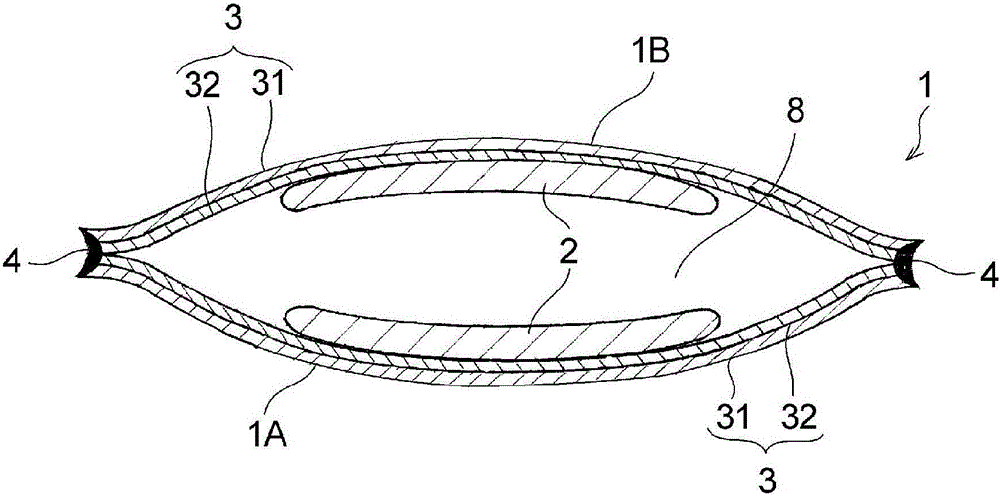

[0023] In practice, a sheet-welded body in which a plurality of sheets are welded to each other in an overlapping state requires sufficient weld strength so that the plurality of sheets welded to each other at the welded portion will not be peeled apart during normal use. However, in the sheet welded body obtained by performing fusing and welding at the same time described in Patent Documents 2 and 3, the welded portion (sealing edge in which the edges of a plurality of sheets are welded in a state where the edges of the sheets are overlapped) formed by irradiating laser light Since the welding strength between the sheets of the part) is insufficient, the welded part may be broken during normal use and a plurality of sheets may be scattered. In addition, when the sheet welded body is used to manufacture products (sanitary products) that are used in contact with the skin, such as absorbent articles, the welded part is required to have good softness and skin feel, but in Patent D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com