A heat exchange system for a gallery type incubator

A heat exchange system and roadway-type technology, applied in the field of heat exchange systems, can solve the problems that the quality of chicks is not as good as that of single-stage incubators, the temperature gradient is not obvious, and waterfowl eggs cannot be hatched, so as to improve the hatching efficiency and practicality. The effect of using range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following will be further elaborated in conjunction with specific embodiments and diagrams.

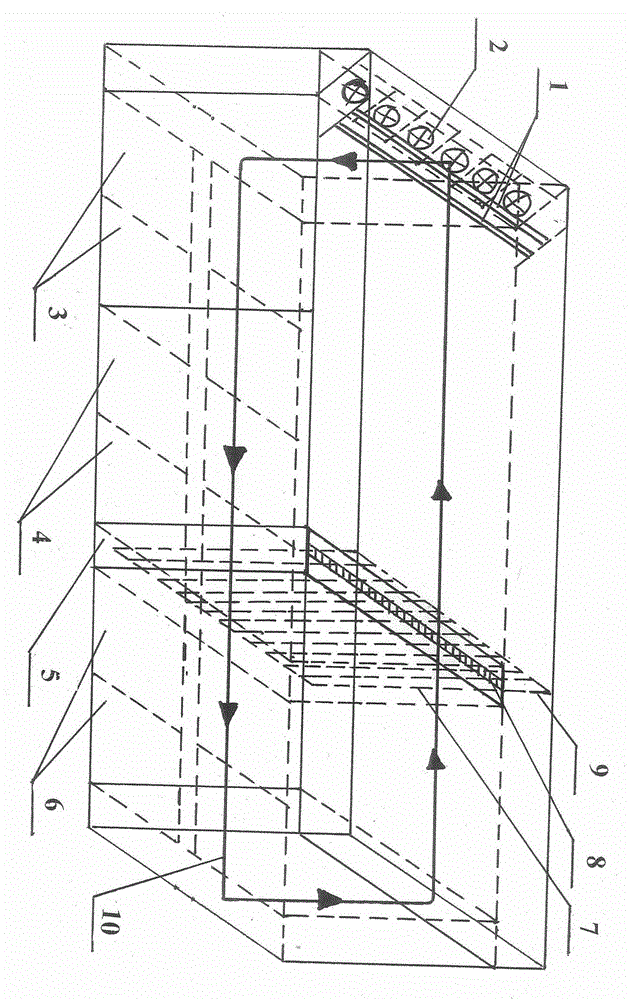

[0008] Such as figure 1 As shown, the heat exchange system of the roadway incubator includes a heating device 1, a fan 2, a pre-stage area 3, a mid-stage area 4, a buffer zone 5, a post-stage area 6, a refrigeration device 7, a heat exchange device 8, a heating device 9, Composed of "O" type airflow 10, the tunnel type incubator can be divided into a return air area and an incubation area, and the incubation area includes the early stage area 3, the middle stage area 4 and the later stage area 6, and is characterized in that: in the middle stage area 4 of the incubation area A buffer zone 5 is further set up between the buffer zone 6 and a cooling device 7 in the buffer zone 5 to reduce a certain temperature. The buffer zone 5 is equipped with a heating de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com